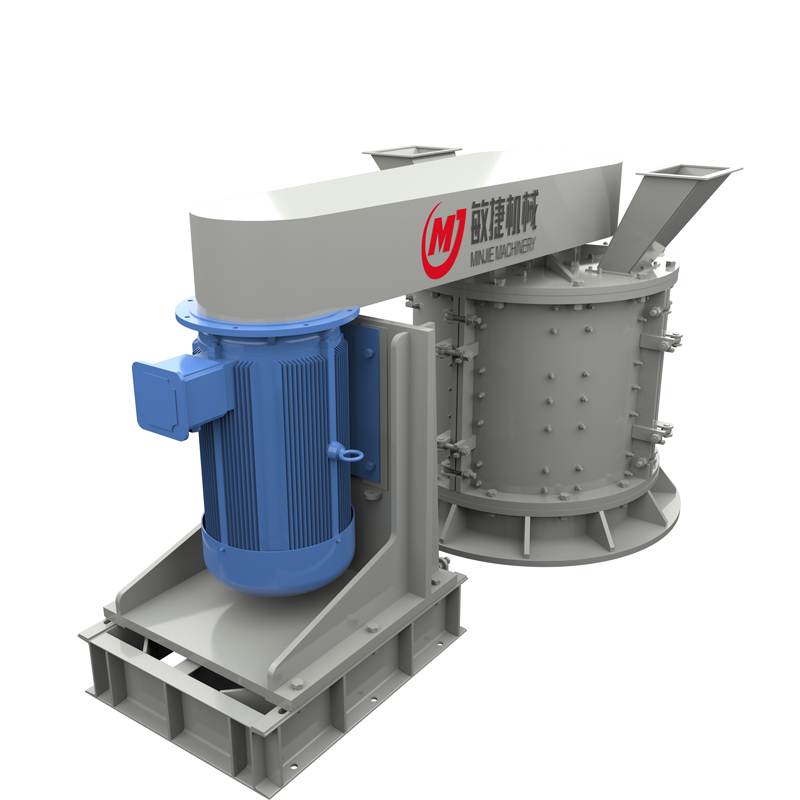

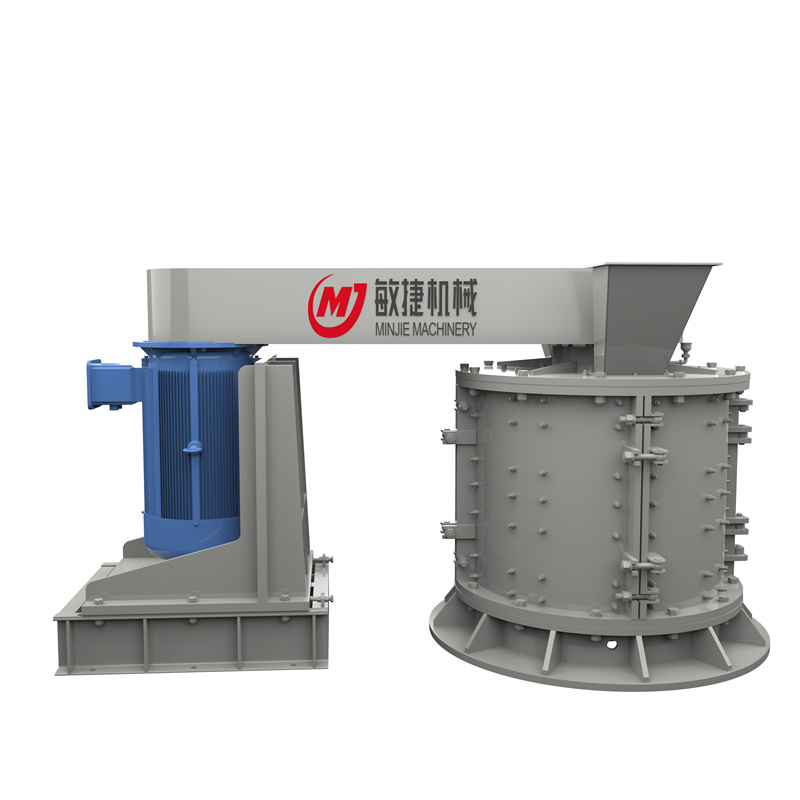

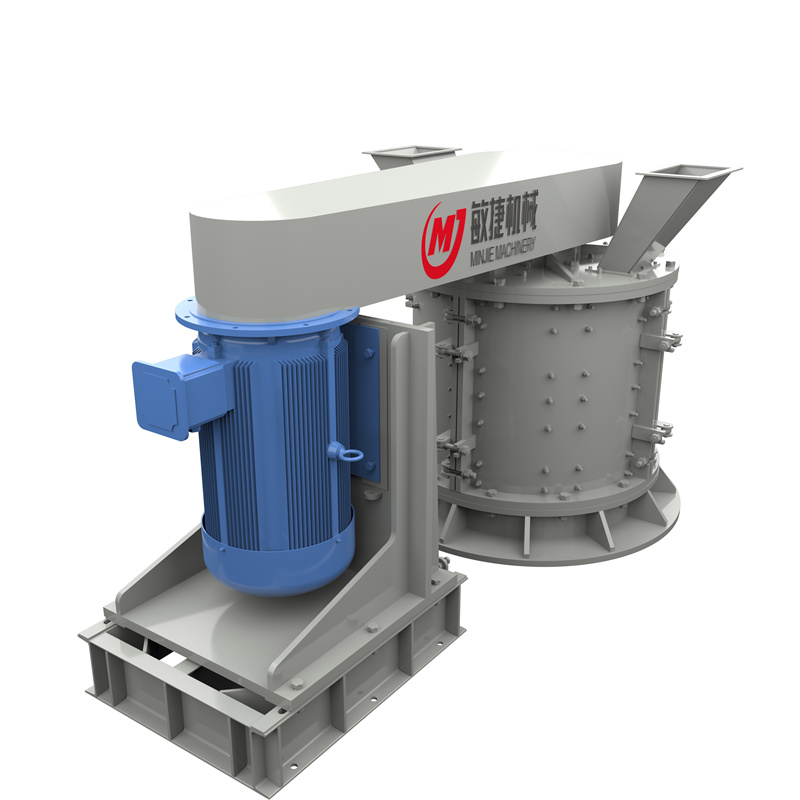

Vertical Crusher for Ore Processing

Product Introduction

The working principle of vertical composite crusher is to use plate hammer impact and extrusion to break materials. The general material is added to the finished product from the feed port, and the time in the crushing chamber is only 2 ~ 3s. So the material through the large volume, high output. The crusher has two upper and lower hammer frames, the upper hammer frame has 4 plate hammers, and the lower hammer frame has 6 plate hammers.

The vertical composite crusher is a collection of two crushing material methods in one body: the first reflects the characteristics of the impact crusher, the large material is broken by high-speed impact, and becomes a small piece of material; The second reflects the characteristics of the extrusion machine, small pieces of material after impact, extrusion and broken, the product into powder and small particles; The broken material falls in a rotating motion in the body, so that the material is fully broken. In this way, the material discharged under the impact and extrusion is not the cake, but the loose body of the material. Therefore, the products of the vertical composite crusher do not need to use the breaking equipment.

The rotor component is the key component in the vertical composite crusher. The upper and lower hammer frame is cast as a whole, with good rigidity and balance. The static balance treatment after the rotor assembly further ensures the balance.

The machine is widely used in building materials, metallurgy, mining, coal, chemical and power industries, such as crushing cement clinker, gypsum, limestone, sandstone, blast furnace slag, iron ore, gold ore, molybdenum ore, stone, lump coal, asbestos ore, phosphate rock and other medium hardness materials. For example, the vertical composite crusher using a new type of high chromium alloy plate hammer can break high hardness materials such as river pebbles.

Main technical parameters

| Model | PLF-1000 | PLF-1500 |

| mm Cylinder diameter | Ø1000 | Ø1500 |

| r/min Spindle speed | 620 | 410 |

| mm Feed size | ≤80 | ≤120 |

| mm Discharge particle size | 5-8 | ≤5 |

| (t/h) Production capacity | 30~50 | 50~70 |

| kW Motor power | 75 | 132 |

| kg Weight | 7850 | 15243 |

| mm External dimensions(length,width,height) | 2838x1500x1800 | 4248x2100×2250 |

| Starting method | Soft startup | Soft startup |