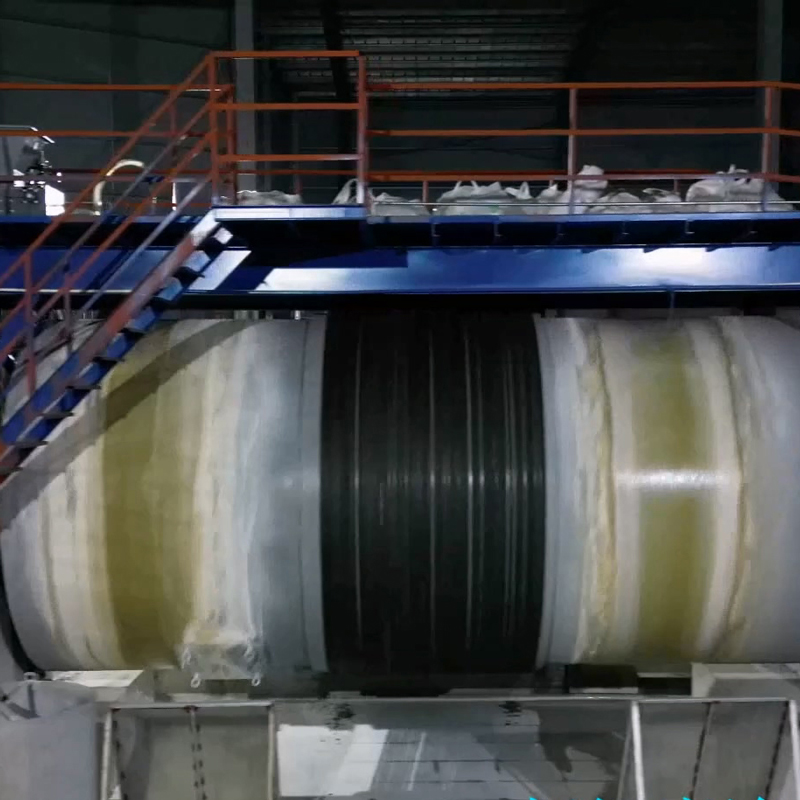

Ultrafine Grinding Continuous Ball Mill

Product Video

Product Introduction

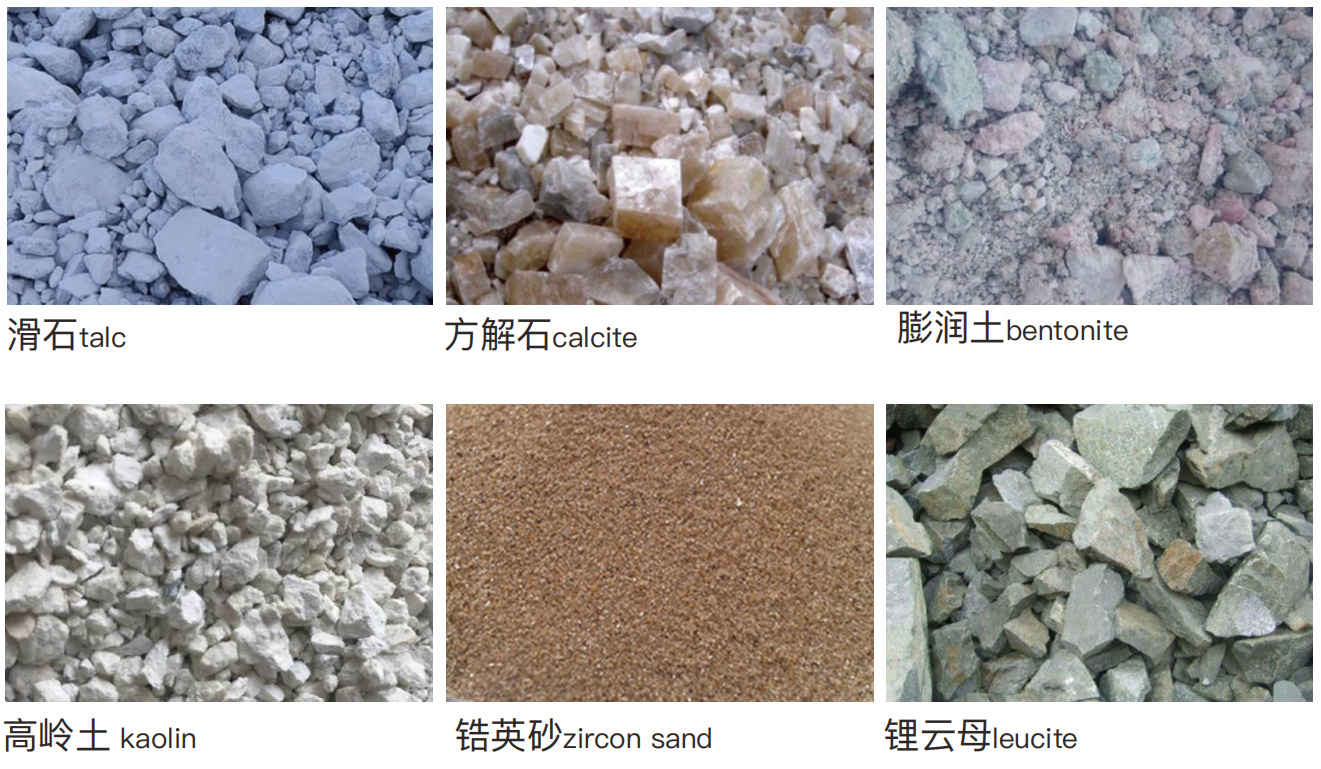

The ultrafine ball mill is suitable for wet ball milling and dry ball milling. Operation mode can be intermittent ball milling, continuous ball milling. Can be used for grinding potassium albitite, quartz, limestone, talc, calcite, dolomite, fluorite, bentonite, kaolin, zirconite sand, lepiolite and other materials, is the necessary grinding industry of medium and high hardness material grinding equipment, grinding fineness of 100~10000 mesh, can be customized according to customer needs.

Key Features

Continuous Operation: Materials are fed and discharged simultaneously, allowing uninterrupted production and stable output.

Ultrafine Grinding Capability: Achieves particle sizes typically in the range of 1 to 20 microns, suitable for high-precision applications.

Optimized Design: Features specially designed grinding media and liners for enhanced energy efficiency and reduced wear.

Adjustable Parameters: Fine control over residence time, speed, and media size for customizable fineness and throughput.

Closed System Compatibility: Can be operated in a closed-loop with classifiers or cyclone separators to control particle size distribution precisely.

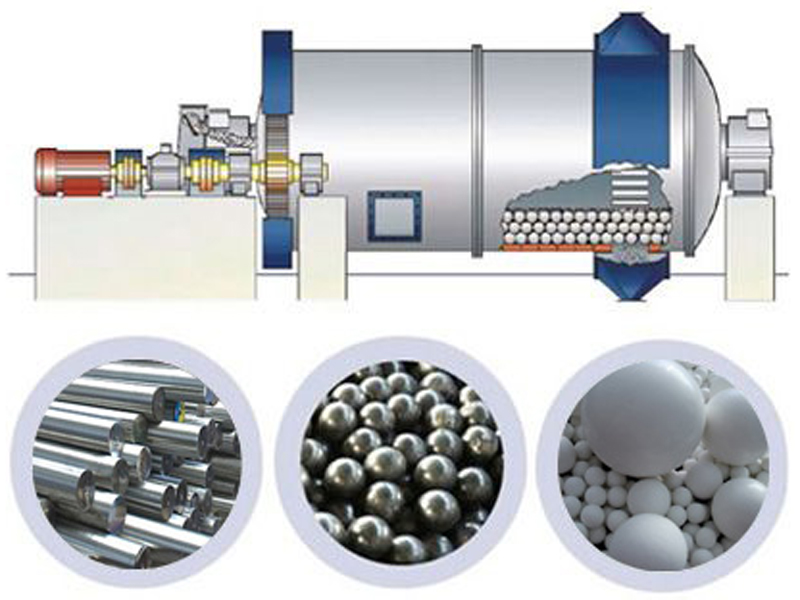

Product Accessories

Specialized Grinding Balls and Liners for Ultrafine Continuous Ball Mills

Minjie’s specialized grinding media and liners for ultrafine continuous ball mills offer precise and stable solutions for demanding materials such as lithium ore, graphite, zirconium silicate, and pigments or dyes. The grinding media, including high-alumina balls and zirconia balls, feature excellent wear resistance and minimal contamination—ideal for applications requiring strict control of purity and particle size distribution.

For lithium mica, spodumene, and other new energy materials, the grinding balls maintain high efficiency and low wear even under heavy loads, ensuring zero metallic contamination. For flake materials like graphite or sticky pigment compounds, the optimized size and density of media improve dispersion and prevent agglomeration.

Liners are made from high-strength ceramic plates or high-alumina materials, providing tight structure and excellent impact resistance. Custom formulas are available based on the corrosiveness and hardness of different raw materials, extending equipment life and reducing maintenance frequency.

This integrated solution delivers stable performance, high throughput, and low energy consumption—making it a top choice for industries in new energy, advanced materials, and fine chemicals.

Applications

Quartz and other silicate materials

Calcium carbonate, talc, barite, and other minerals

Ceramic raw materials

Pigments and fillers

Advanced materials in chemical and electronic industries

Advantages

Consistent and uniform particle size

High throughput with reduced energy consumption

Low contamination and high product purity

Minimal manual intervention and easy integration into automated systems