Single Continuous Ball Mill for Mineral Processing

Product Video

Product Introduction

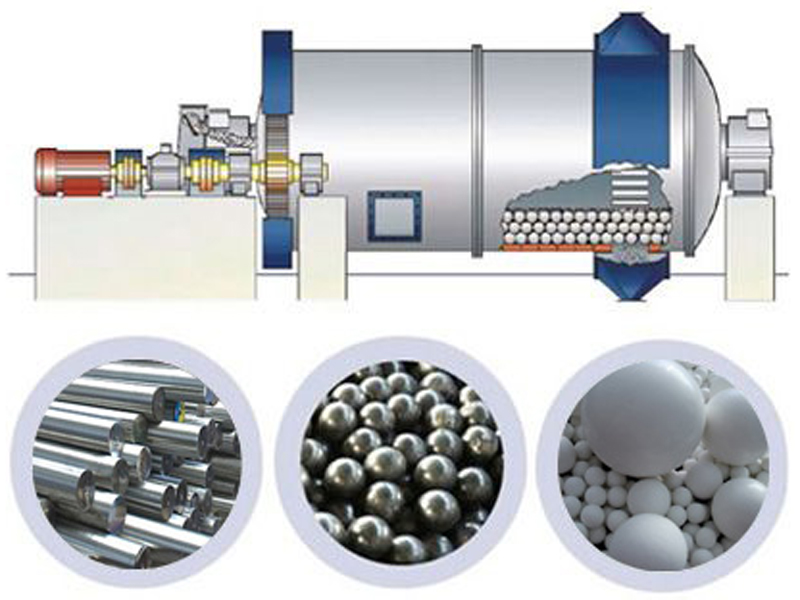

Single continuous ball mill applicable materials: Steel slag, white ash, gold ore, aluminum powder, quartz sand, aluminum powder paste, hematite, high aluminum porcelain, iron concentrate powder, fluorite ore, barite, coal slime, tungsten carbide, copper, potassium albite, talc and other mineral grinding, widely used in cement, silicate products, all kinds of ore, raw materials are sent to the drum feeder at the front of the ball mill. With the operation of the ball mill, raw materials and water are continuously sent into the ball mill cylinder by the drum feeder. The inner wall of the ball mill cylinder can be installed with high manganese steel lining or high aluminum lining brick or rubber lining according to the raw material particles and the fineness of the pulp. At the same time, high chromium steel ball or high aluminum pebble can be loaded as the grinding medium. Finally, the coarse particles are sent back to the ball mill by the return belt, and the finished stock is sent to the subsequent process end.

Product Accessories

Ball Mill Accessories: Steel Balls & Liners

Steel balls and lining plates play a critical role in the efficient operation of a ball mill. Our high-quality steel balls are made from premium alloy steel and undergo strict heat treatment processes to ensure excellent wear resistance and impact toughness. They deliver consistent, high-efficiency grinding performance under continuous rotation.

The wear-resistant lining plates are crafted from high-manganese or high-chromium steel, effectively preventing direct abrasion between raw materials and the mill shell. This extends the service life of the equipment and reduces maintenance costs. Both components are precisely manufactured to ensure uniform size, stable hardness, and compatibility with a wide range of milling requirements.

Whether in ore processing, cement production, or industries like metallurgy and chemical engineering, reliable steel balls and liners are essential for stable operation, reduced energy consumption, and increased overall productivity. Our accessories are available in standard models and can also be customized in size, material, or structure to suit specific working conditions and production needs.

Choosing our ball mill accessories means investing in long-lasting durability, consistent performance, and optimized cost-efficiency. We are committed to delivering dependable components that keep your equipment running at peak efficiency, even under demanding, high-load conditions.