Semi-Continuous Ball Mill for Raw Material Processing

product video

Product Introduction

|

Our ball mill has applied for the following related patents |

||

|

ZL201020685450.6 |

ZL2015106070233.0 |

ZL2015207704250.0 |

|

ZL201220267043.2 |

ZL2015207369816.0 |

ZL2015207368334.0 |

|

ZL201320222036.5 |

ZL2016102972384.0 |

ZL2016204062571.0 |

product accessories

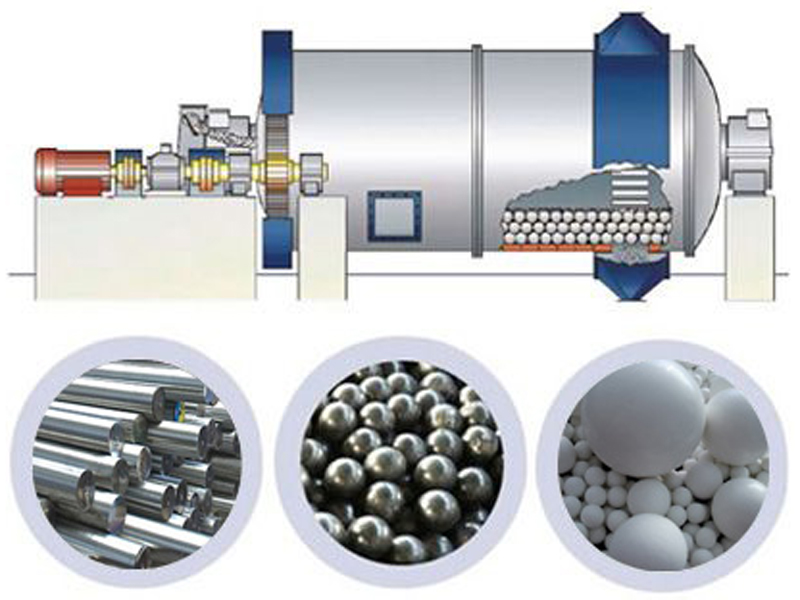

Ball Mill Accessories: Steel Balls & Liners

Steel balls and lining plates play a critical role in the efficient operation of a ball mill. Our high-quality steel balls are made from premium alloy steel and undergo strict heat treatment processes to ensure excellent wear resistance and impact toughness. They deliver consistent, high-efficiency grinding performance under continuous rotation.

The wear-resistant lining plates are crafted from high-manganese or high-chromium steel, effectively preventing direct abrasion between raw materials and the mill shell. This extends the service life of the equipment and reduces maintenance costs. Both components are precisely manufactured to ensure uniform size, stable hardness, and compatibility with a wide range of milling requirements.

Whether in ore processing, cement production, or industries like metallurgy and chemical engineering, reliable steel balls and liners are essential for stable operation, reduced energy consumption, and increased overall productivity. Our accessories are available in standard models and can also be customized in size, material, or structure to suit specific working conditions and production needs.

Choosing our ball mill accessories means investing in long-lasting durability, consistent performance, and optimized cost-efficiency. We are committed to delivering dependable components that keep your equipment running at peak efficiency, even under demanding, high-load conditions.

Process plan description

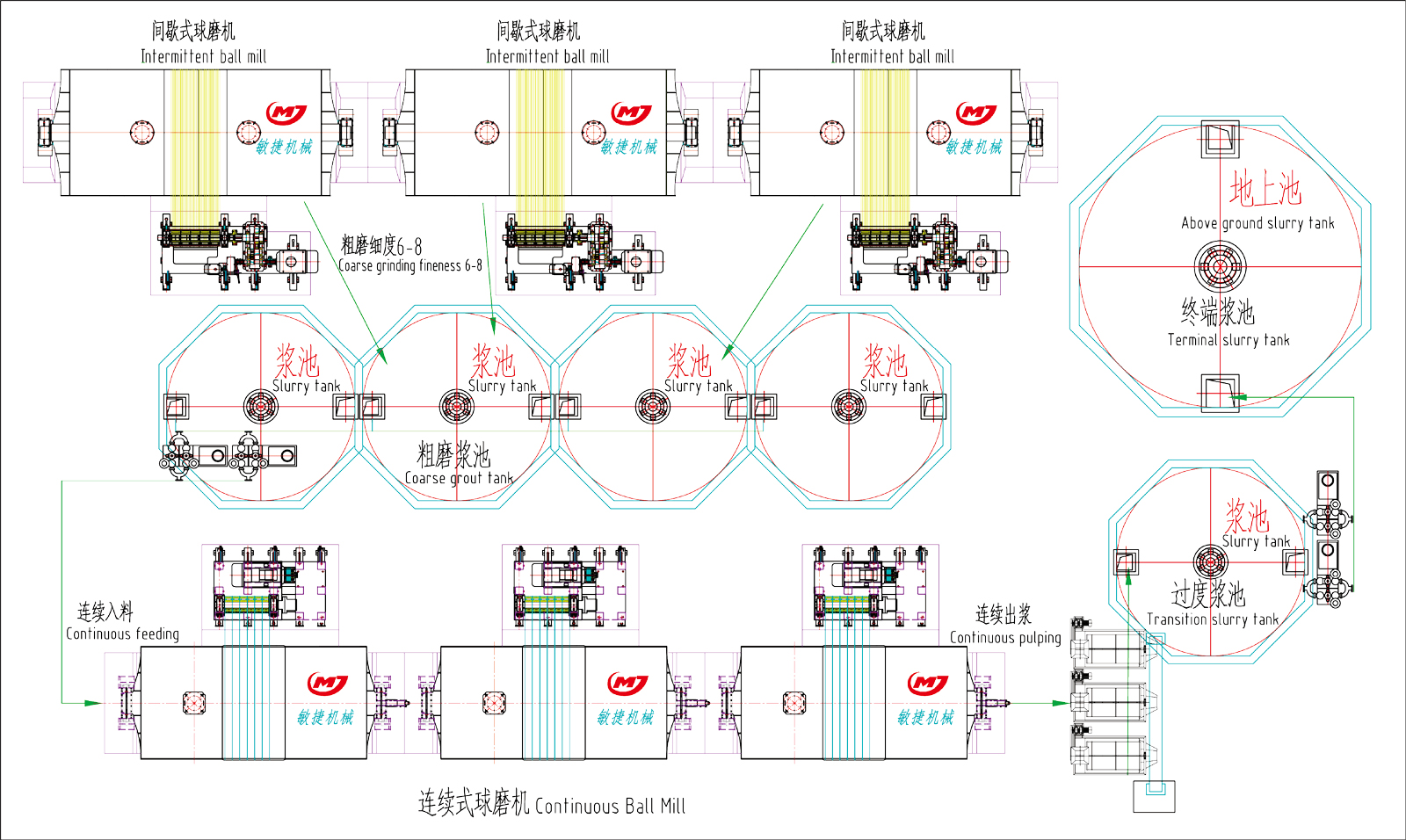

Process scheme description of continuous ball mill supporting intermittent ball mill :(This scheme can use the old intermittent ball mill and is suitable for improvement in the old factory)

1. The pre-treatment and feeding formula of raw materials are directly processed by intermittent ball mill. After grinding to a fineness of 6~8, the slurry is discharged into the underground slurry transfer tank.

2. The slurry in the transfer tank can be directly imported into the inlet of the continuous ball mill through the hydraulic piston pump to adjust the flow rate according to the output and fineness requirements for continuous ball mill operation.

3. continuous ball mill pulp is finished slurry.

Main technical parameters

| model | m ³ volume | m m Cylinder size | k W power | Reducer model | r/min speed | Type of lining | Grinding media |

| QCM3290 | 67 | Ø3200x9000 | 355-6 | ZLY560 | 10-12.5 | Rubber lining | High Alumina Bal |

| QCM3490 | 75 | Ø3400x9000 | 400-6 | ZLY560 | 10-12 | Rubber lining | High Alumina Bal |

| QCM3672 | 67 | Ø3600x7200 | 355-6 | ZLY560 | 9.5-11.5 | Rubber lining | High Alumina Bal |

| QCM3690 | 85 | Ø3600x9000 | 450-6 | ZLY560 | 9.5-11.5 | Rubber lining | High Alumina Bal |

| QCM3890 | 94 | Ø3800x9000 | 500-6 | ZLY560 | 9.5-11.5 | Rubber lining | High Alumina Bal |

| QCM38100 | 105 | Ø3800x10000 | 560-6 | ZLY630 | 9.5-11.5 | Rubber lining | High Alumina Bal |

| QCM4090 | 105 | Ø4000x9000 | 560-6 | ZLY630 | 9-11 | Rubber lining | High Alumina Bal |

| QCM40106 | 123 | Ø4000x10600 | 630-6 | ZLY630 | 9-11 | Rubber lining | High Alumina Bal |

| QCM4286 | 110 | Ø4200x8600 | 630-6 | ZLY630 | 9-11 | Rubber lining | High Alumina Bal |

| QCM42106 | 136 | Ø4200x10600 | 710-6 | ZLY710 | 9-11 | Rubber lining | High Alumina Bal |