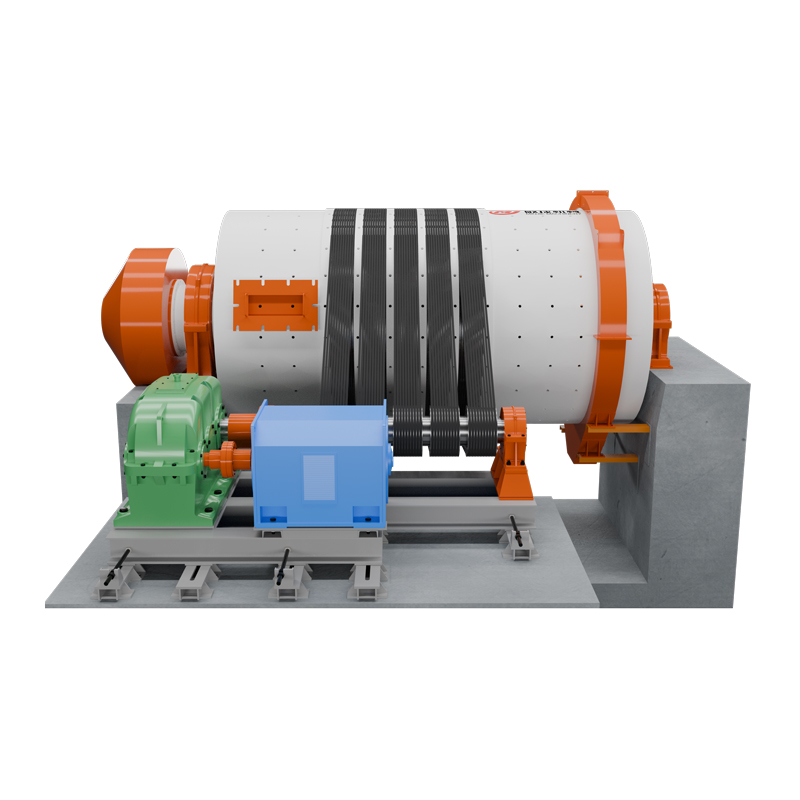

Rod Mill for Mineral Processing

Performance characteristics

The rod mill produced by Minjie Company is different from conventional mining ball mills in that it uses a V-belt drive, and the cylinder belt position is processed into a V-belt groove through a large CNC floor lathe, which can save energy and reduce costs.

Comparison of Belt Drive and Traditional Ring Gear Drive for Minjie Mechanical Mining Ball Mills

| Agile machinery | Transmission form | comparative analysis | |

| transmission structure | belt drive | Ring gear transmission | Ring gear transmission has high noise and maintenance costs |

| Lubrication form | Belt does not require lubrication | Dip-feed Lubrication | The gear ring guard is prone to oil leakage and there is a lot of oil contamination on site |

Main technical parameters

| model | m ³ volume | m m Cylinder size | k W power | r/min speed | m m Ore discharge particle size | t/h production capacity |

| QCZ2736Z | 18 | Ø2800×4100 | 355/400 | 21.7 | 0.15-3 | 40-150 |

| QCZ2745Z | 25.7 | Ø2800×5100 | 400/450 | 21.7 | 0.15-3 | 50-165 |

| QCZ3045Z | 31.8 | Ø3100×5100 | 450/500 | 20 | 0.15-3 | 60-200 |

| QCZ3250Z | 32.3 | Ø3300×5600 | 500/560 | 18.6 | 0.15-3 | 70-230 |

| QCZ3254Z | 39.4 | Ø3300×6000 | 560/630 | 18.6 | 0.15-3 | 80-280 |

Note: The main technical parameters of the standard model are listed in the table above. Corresponding models can be designed according to customer needs, and high-power motors can be designed using medium voltage motors. Customers are welcome to inquire.