Quartz Powder Production Line for Ceramics & Sanitaryware and Construction Matetrial

Key Features

High Efficiency Grinding: Utilizes ball mills, Raymond mills, or vertical roller mills to achieve ultra-fine powder with customizable mesh sizes (from 100 mesh to 2500+ mesh).

Precision Classification: Equipped with air classifiers or cyclone separators to ensure uniform particle size distribution.

Dust-Free Operation: Features advanced dust collection systems and enclosed processing to maintain environmental safety and minimize material loss.

Automation & Control: Integrated with PLC systems for real-time monitoring, easy operation, and consistent product quality.

Customizable Capacity: Designed to meet production capacities ranging from a few tons per day to hundreds of tons per day, depending on the client's requirements.

Applications

Glass and Ceramics Manufacturing

Electronics and Semiconductors

Paints, Coatings, and Plastics

Construction Materials (e.g., engineered stone)

Foundry and Metallurgical Processes

Advantages

High product purity (SiO₂ content typically >99.5%)

Low maintenance and long service life

Energy-efficient design

Flexible configurations for different industrial uses

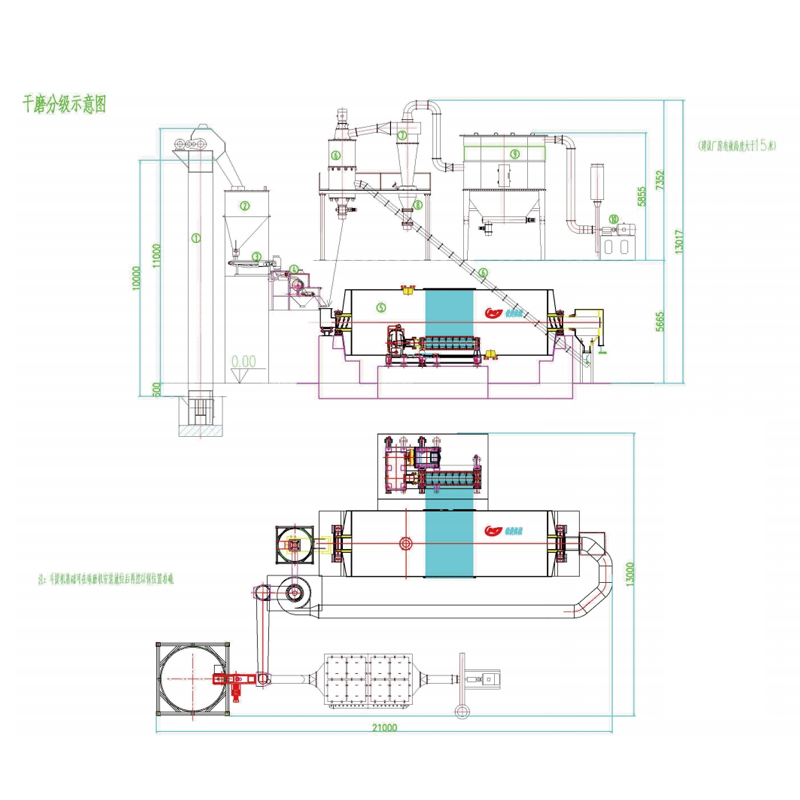

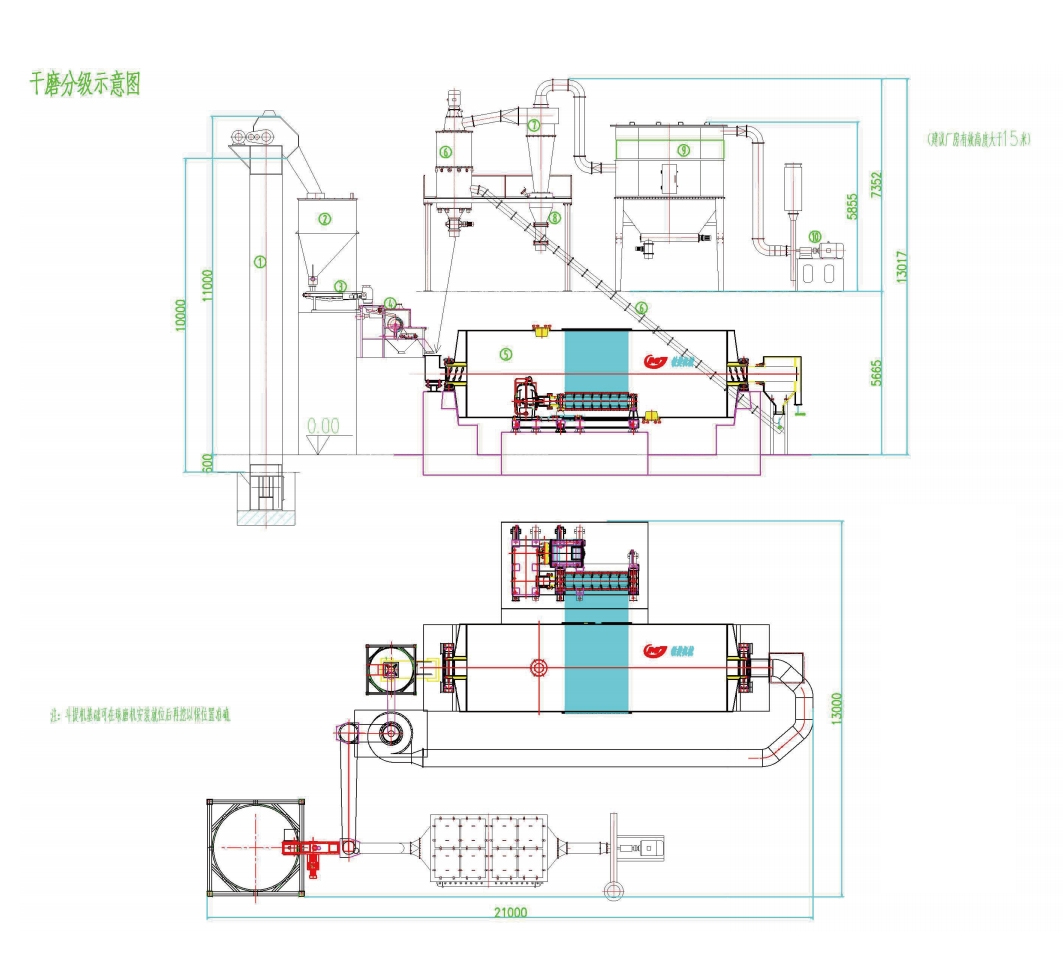

Equipment configuration

1 bucket elevator

2 transfer material bin

3 weighing belt machine

4 magnetic separator

5 grinding ball mill

6 Air classifier

7 cyclone collector

8 powder buffer bin

9 bag dust collector

10 high pressure induced draft fan

Product features

1. Theory and practice optimize system configuration, minimize energy consumption, scientific dust removal design of each dust point of the system, effectively control dust spillover, in line with national environmental protection requirements;

2. International standard production line, according to the different requirements of customers, customized design and manufacturing, equipment stable and reliable operation;

3, The equipment is easy to operate. PLC automatic control can be designed according to the requirements. From grinding to grading to packaging, the whole process is automatically controlled, reducing labor intensity and saving production costs;

4. The graded impeller blade adopts polymer wear-resistant material, which effectively solves the wear problem of the graded impeller;

5. The entire production process for ultra-pure wear protection, according to the difference in production conditions, ball mill lining can be selected ceramic lining or quartz lining, grinding medium can choose ceramic ball or quartz ball, the entire classification system is protected by ceramic sheets, so that the entire production process does not contact metal, to ensure product purity and extend the service life of the equipment.

Main technical parameters

| Item | Model | ||||||

| AMF-50 | AMF-100 | AMF-200 | AMF-400 | AMF-600 | AMF-800 | AMF-1200 | |

| Ball mill model | Ø1200x4500 | Ø1500x5700 | Ø1830x7000 | Ø2200x7000 | Ø2400x7500 | Ø3000x9000 | Ø3500x13000 |

| Class type number | HFZ050 | HFZ100 | HFZ200 | HFZ400 | HFZ600 | HFZ800 | HFZ1200 |

| Total production line power(Kw) | ≤7.5 | 145 | 225 | 345 | 550 | 850 | 1650 |

| Processing capacity(Kg/h) | 800-1800 | 1200-1800 | 3500-4000 | 5000-6000 | 7000-8000 | 10000-20000 | 15000-30000 |

| Output(kg/h) | 480-600 | 720-1080 | 2100-2400 | 3000-3600 | 4200-4800 | 6000-15000 | 10000-20000 |

| Fineness(um) | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 | 5-50 |

| Classification accuracy | D97 | D97 | D97 | D97 | D97 | D97 | D97 |

| Filter area(m2) | 50 | 70 | 100 | 200 | 200 | 360 | 440 |

| Dust concentration (mg/m3) | 40 | 40 | 40 | 40 | 40 | 40 | 40 |