Those Things About Chromium Ore Mining: Processes, Challenges and Underlying Value

Statistics show that over 90% of global chromium ore is mined through open-pit mining. This is mainly because chromium ore is primarily found in ultra basic magma. To put it simply, the magma contains a large amount of chromium. As the magma erupts, massive chromium is brought to or near the Earth's surface. After cooling and crystallization, this forms large-scale chromium ore layers suitable for open-pit mining.

In terms of the global distribution of chromium ore resources, the top-ranking countries include South Africa, Kazakhstan, and India.

Now let’s talk about the chromium ore mining process.

Although most chromium ore is distributed near the Earth's surface, the ore still contains a large amount of gangue (waste rock). Therefore, pre-treatment is required before rough separation.Chromium ore has a Mohs hardness of approximately 5.5-7.5, so it needs to undergo multi-stage crushing and fine grinding:

Coarse crushing: As the initial size-reduction step, raw ore is crushed to a particle size of 200–300 mm using a jaw Crusher, which provides the foundational particle size needed for subsequent processing.

Medium crushing: Following coarse crushing, the previously crushed ore is further reduced to 10–20 mm via a cone crusher, refining the particle size to bridge the gap between rough and fine processing stages.

Fine crushing: Next, an impact crusher and a roll crusher are used in tandem to crush the ore to less than 10 mm, ensuring the material meets the strict size requirement for the final grinding step.

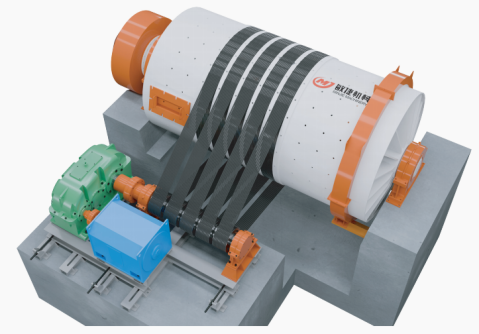

Fine grinding: Finally, a wet ball mill is employed to grind the ore to a particle size of around 200 meshes exactly, completing the size-reduction process to prepare the ore for downstream mineral separation.

Next is the Mineral Processing process:

● Rough Separation: Following the completion of fine grinding, the ore enters the initial stage of mineral processing, where gravity separation is first employed to separate and remove the majority of gangue, laying a foundational step for subsequent concentration processes by reducing unnecessary material load.

Equipment Selection

● Jig separator: In the operation of this equipment, the material that sinks to the bottom is classified as coarse concentrate, while the tailings—carried by the flow of water—are discharged from the system, ensuring efficient separation of valuable minerals from waste.

● Spiral chute: Moving on to this next processing tool, it is specifically designed to handle fine-grained pulp ore with a particle size ranging from 0.074 to 1 mm. This separation process works by utilizing the combined forces of centrifugal motion and gravity, which together drive the effective sorting of mineral particles based on their density differences.

Concentrate Separation

At this concentrate separation stage, even after the prior rough separation process, the ore pulp still contains residual impurities such as iron ore and serpentine, which need to be further removed to improve the purity of the target chromium concentrate.

Equipment Selection

● Permanent magnetic drum separator: In the concentrate separation process, this equipment leverages its magnetic properties to target chromium spinel— a mineral with weak magnetism— which gets adsorbed onto the drum surface. In contrast, other non-magnetic ores (such as the residual iron ore and serpentine mentioned earlier) are carried away and discharged along with the flowing ore pulp, ensuring the initial purification of the chromium concentrate.

● Alternative equipment option: When dealing with scenarios where there is a significant density difference between the remaining gangue and chromium spinel, shaking tables or centrifugal concentrators can be selected as effective separation tools. These devices utilize the density variation between the two materials to achieve precise sorting, complementing the magnetic separation method and further enhancing the purity of the final chromium product.