The Entire Process of Tile Manufacturing: A Craftsmanship Journey from Ore to Home Aesthetics

A seemingly ordinary tile, from ore buried deep underground to decorative material that covers home floors and walls, hides a sophisticated and complex industrial process behind it.

The first step in tile manufacturing is "raw material selection and pretreatment", which is the foundation for determining tile quality. In factories, high-purity natural minerals such as quartz sand, feldspar, and clay are preferred as raw materials. Quartz sand enhances the hardness and wear resistance of tiles; feldspar lowers the firing temperature and improves tile stability; while clay gives the raw materials plasticity, facilitating subsequent shaping.

These raw materials are not used directly but undergo multiple screening processes: first, a vibrating screen removes large impurities and stones, and then they are sent to a Ball Mill for wet grinding. During the grinding process, raw materials are mixed with water in a specific ratio and ground into a fine, uniform slurry. Only in this way can it be ensured that the raw materials bond tightly during subsequent shaping, preventing issues such as cracking and delamination of tiles.

The ground slurry then enters the "press forming" stage, which is equivalent to "shaping" the tiles. The fine slurry is first processed by a spray dryer, forming loose dry powder particles at a high temperature of 180-220°C. This not only retains the plasticity of the raw materials but also prevents tile deformation due to excessive moisture during forming. Subsequently, the dry powder particles are sent to a large hydraulic tile press, where they are pressed into "green bodies" with the same dimensions as the final tiles under high pressure of thousands of tons.

"Glazing and decoration" is a crucial step that transforms tiles from "plain green bodies" into "aesthetic products". Depending on the type of tile, glazing methods vary: for ordinary glazed tiles, factories use methods such as glaze pouring and glaze spraying to evenly coat the surface of the green bodies with glaze. Glaze not only improves the waterproofness and stain resistance of tiles but also can present rich colors and textures by adding different colorants.

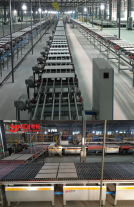

The subsequent "high-temperature firing" is the core link for tiles to "harden and set their shape". The glazed green bodies are neatly stacked in a kiln and undergo three stages of high-temperature processing: "preheating - firing - cooling".

- The preheating stage mainly removes moisture and organic matter from the green bodies to prevent tiles from cracking during firing.

- The firing stage is critical: at this point, a series of physical and chemical reactions occur in the minerals of the raw materials, gradually sintering into a dense ceramic structure, and the glaze layer also melts, flows, and bonds tightly with the green body.

- The cooling stage requires slow temperature reduction to avoid internal stress in tiles caused by excessive temperature differences. The entire firing process usually takes 20-40 hours, and parameters such as temperature and transmission speed inside the kiln need to be monitored in real-time. Any deviation may affect the strength, flatness, and color of the tiles.

Tiles after firing are not directly delivered from the factory; they also undergo strict screening in the "post-processing and quality inspection" stage. First, the tiles undergo edge grinding: edge grinders smooth the edges of the tiles to ensure uniform gaps when joining. Some tiles also require polishing: the surface of the tiles is polished to a mirror-like finish using the grinding heads of a polishing machine to enhance glossiness.

In the quality inspection link, specialized mechanical equipment checks each tile for dimensional deviation, flatness, and flexural strength to ensure consistent color of products in the same batch.

From raw material grinding to high-temperature firing, from aesthetic decoration to strict quality inspection, I can feel the "precision and craftsmanship" of modern tile manufacturing in every link. A small tile not only carries the essence of natural minerals but also embodies the wisdom of industrial technology.