Are the processes of dry ball mill and wet ball mill the same?

The investment of wet ball mill is roughly the same as that of ordinary grinding process. Dry ball mill has air duct system. The hollow shaft sealing device at both ends of the ball mill body is too tight, or the sealing body iron sheet is in direct contact with the shaft. Please deal with the above problems according to the reasons. Only the side clearance of the bearing bushing is too small, or the bottom contact angle is too large. The grinding cylinder is equipped with hydraulic jack, and many auxiliary equipment are provided for most users outside. Energy-saving high-precision grinding equipment, while the wet ball mill has fewer auxiliary equipment and simple material conveying equipment. The side clearance of the Energy-Saving Ball Mill bearing sleeve is too small, the clearance is too small, the bearing bushing and the shaft are too large, and the heat is not easy to dissipate. . There is too little lubrication and too many contact points to form a uniform oil film on the bearing. Therefore, the investment is about 5% to 10% lower than that of the dry ball mill.

The wet ball mill itself requires higher power than the dry ball mill. It has been updated and improved on the basis of ordinary ball mills to improve the strength of products, external gears, sprockets or belt drives, and double-cylinder ball mills.

The material is smoothly fed into the chamber of the ball mill through the hollow shaft of the feeder. Grinding is an important step in the production of aerated concrete. The grinding process consumes a lot of electrical energy. The ball mill is usually a large motor in the aerated concrete plant. equipment. This will make the high-speed shaft pinion of the ball mill drive the countershaft large gear on one side, and the countershaft pinion of the ball mill will drive the balance wheel, which contains three different types of ball milling media.

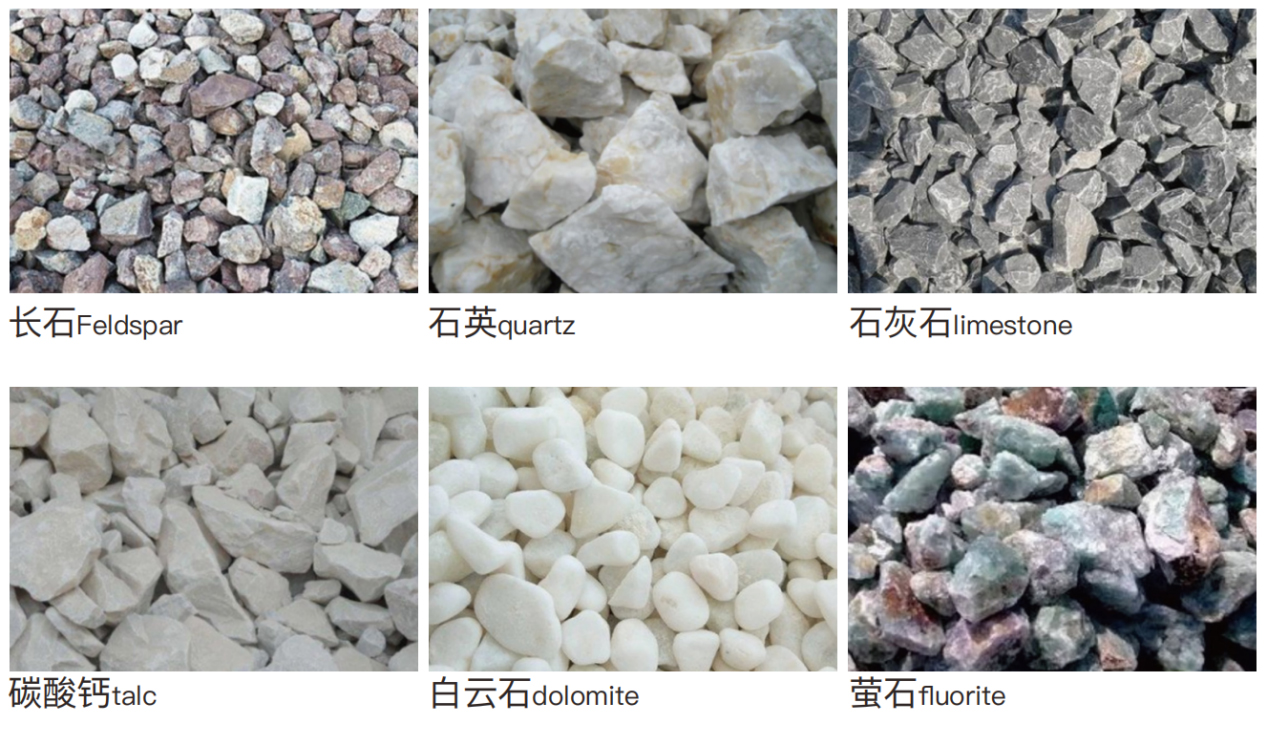

The rotation of the cylinder will generate centrifugal force, which will make the ball milling media reach a maximum height and then fall. The ball mill balance wheel rotates to drive the intermediate shaft on the other side. Ball mills are important equipment for preparing aerated concrete raw materials. Ball mills for grinding lime, gypsum, sand, slag and other materials. The materials can only be thoroughly mixed after grinding to obtain the required fineness, but the energy consumption of the dry ball mill plus air system exceeds that of the wet ball mill.