Analysis of Types and Characteristics for Liners of Ball Mills and Crushers

In the material grinding process of mining, building materials, chemical industry, and other industrial fields, the stable and efficient operation of Ball Mills is inseparable from the crucial support of liners. As the "protective barrier" and "grinding auxiliary body" for the inner wall of the ball mill cylinder, liners not only have to resist the continuous impact and wear from grinding media and materials but also need to adjust their own performance according to different grinding conditions and material characteristics to meet diverse production requirements. Based on differences in material and performance, ball mill liners are mainly divided into two major categories: metal liners and non-metallic liners. Relying on their unique structural designs and material advantages, these two types of liners play important roles in different working environments and together form a liner system that meets the differentiated needs of industrial grinding.

Whether it is metal liners with high strength and impact resistance or non-metallic liners with the advantages of light weight and low noise, ball mill liners of different materials have different focuses in terms of performance. They are not only suitable for a variety of grinding conditions but also have their own applicable scopes and limitations. Below, we will conduct a detailed analysis of the core advantages and potential shortcomings of various liner materials, providing a reference basis for subsequent selection and application.

● Metal Liners

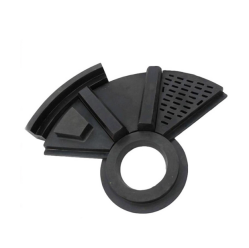

High-Manganese Steel Plates for Ball Mills: These are used to protect the ball mill cylinder, preventing the cylinder from direct friction and impact from materials. Meanwhile, high-manganese steel liners of different designs are also used to adjust the movement state of grinding media, so as to enhance the grinding and crushing effect on materials.

High-Chromium Cast Iron Liners for Ball Mills: They possess excellent wear resistance and high-temperature ductility, along with high hardness. Especially under low-load impact, they exhibit superior resistance to wear.

Alloy Liners for Ball Mills: Depending on the added elements, combined with appropriate smelting and heat treatment processes, these liners obtain special properties such as high strength, high toughness, high wear resistance, corrosion resistance, low-temperature resistance, high-temperature resistance, and non-magnetism.

● Non-Metallic Liners

Rubber Liners: Compared with manganese steel liners, rubber liners have the advantages of low density, light weight, energy saving, wear resistance, impact resistance, low noise, easy installation, and corrosion resistance. They can significantly reduce the consumption of steel balls, thereby lowering production costs and improving production efficiency. However, their drawback is poor high-temperature resistance, making them unsuitable for dry-process mills.

● Crusher Liners

High-Manganese Steel Liners: As the most traditional liner material, they undergo work hardening when subjected to strong impact. Their surface hardness increases rapidly, and wear resistance is significantly enhanced. They are suitable for crushing high-hardness and high-impact materials such as granite and basalt, and are often used in parts like the plates of jaw Crushers.

High-Chromium Cast Iron Liners: With extremely high hardness and resistance to wear, they are often used in components such as the liners of cone crushers.

Alloy Wear-Resistant Steel Liners: By adjusting the alloy composition, these liners achieve a balance between hardness and toughness. They can withstand a certain degree of impact while having excellent wear resistance, making them an ideal choice for complex working conditions and applicable to various types of crushers.

In summary, the selection of liner materials for ball mills and crushers always centers on two core aspects: "adaptation to working conditions" and "balance of performance". Metal liners excel in high strength and impact resistance, making them suitable for heavy-load scenarios such as rough grinding and crushing of high-hardness materials. Non-metallic liners, on the other hand, meet special needs like high-purity material grinding and environmental noise reduction with their characteristics of low noise, corrosion resistance, and high precision. In actual production, comprehensive considerations should be given to material hardness, grinding/crushing precision requirements, operating temperature, environmental standards, and cost budgets. Only in this way can liners fully play their role in protecting equipment and improving efficiency, providing solid support for the stable production in fields such as mining, building materials, and chemical industry.