Wholesale Quartz Mineral Processing Solutions - Leading Exporters & Suppliers

For high-quality Mineral Processing Of Quartz, turn to us. With extensive experience in the industry, we offer innovative solutions tailored to meet your specific needs. Our processing methods enhance the purity and efficiency of quartz, positioning us as a trusted choice among buyers in China. As a leading exporter and supplier, we pride ourselves on delivering state-of-the-art machinery and equipment that optimize your operations. Our advanced technologies guarantee excellent results, whether in mining, ceramics, or other sectors reliant on quartz. At Fujian Minjie Machinery Co., Ltd., we prioritize reliability and performance, ensuring our products surpass industry standards. Partner with us for your mineral processing requirements and achieve your business objectives effectively.

The Ultimate Guide to Mineral Processing Of Quartz Delivers Unmatched Quality Service

In the dynamic world of mineral processing, quartz stands out due to its versatility and wide applications across various industries. For businesses looking to enhance their product quality while optimizing operational efficiency, exploring advanced mineral processing techniques for quartz is crucial. This guide delves into the essentials of quartz processing, showcasing methods that ensure high purity and superior performance in ceramic applications. With over 30 years of dedicated experience, the development and industrialization of ceramic machinery have reached new heights, focusing on delivering precision and reliability. The latest trends in quartz processing emphasize automated systems and superior technology that streamline operations. By implementing cutting-edge machinery and techniques, manufacturers can significantly reduce waste and enhance the quality of their final products. Investing in advanced processing machinery not only improves efficiency but also allows global suppliers to maintain a competitive edge in the market. Furthermore, understanding the unique characteristics of quartz and its behavior during processing is essential. Proper techniques can lead to consistent particle size, improved material properties, and reduced environmental impact. As industries continue to evolve, businesses must stay informed about the latest innovations in mineral processing to ensure they provide unparalleled quality service. Adopting these practices will not only boost production but also contribute to a sustainable future in the ceramic industry.

The Ultimate Guide to Mineral Processing Of Quartz Delivers Unmatched Quality Service

| Process Stage | Description | Equipment Used | Efficiency (%) | Notes |

|---|---|---|---|---|

| Crushing | Breaking down quartz into smaller pieces | Jaw Crusher | 85 | Initial stage in processing |

| Grinding | Further reducing the size of quartz | Ball Mill | 90 | Important for liberation |

| Flotation | Separating quartz from impurities | Flotation Cell | 95 | High selective separation |

| Dehydration | Removing moisture from quartz | Filter Press | 92 | Critical for final product |

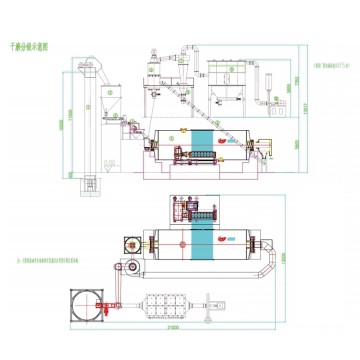

| Drying | Further moisture removal and product stabilization | Rotary Dryer | 97 | Final step in processing |

Comprehensive Comparison of Mineral Processing Of Quartz Stands Out Pioneers in the Field

A

Amelia Thompson

Superior quality and fast delivery! The staff was always courteous and helpful.

03 June 2025

J

James Jones

Incredible item! The quality is evident, and I received superb support.

06 July 2025

W

William Wood

The quality is excellent, and the support staff were professional and attentive.

26 June 2025

A

Austin Thompson

High-quality product delivered with outstanding service. I will definitely be back!

27 June 2025

R

Ruby Hughes

The craftsmanship is top-notch. The customer service team is very diligent!

07 June 2025

G

Grant Phillips

I am thrilled with my purchase! The support team was exceptional and very friendly.

04 July 2025