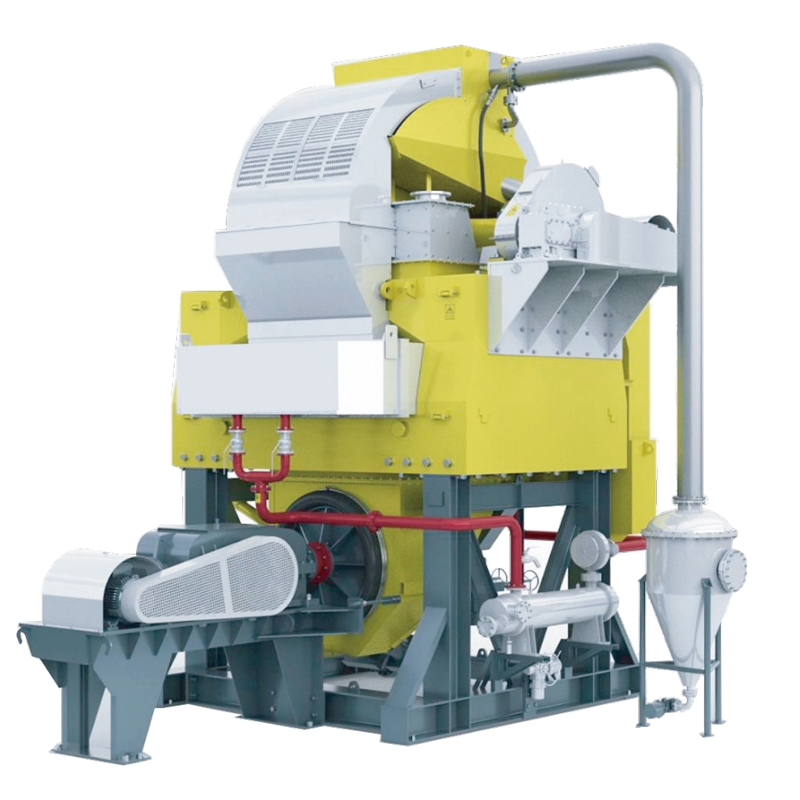

Magnetic Separator for Mineral Processing

Product features

1. Oil-water composite cooling vertical ring high gradient magnetic separator has an advanced cooling system, the coil is fully sealed forced oil cooling external circulation, the principle of oil-water heat exchange, with flushing water quickly take away the heat generated by the coil, so that the coil temperature rise is less than 25℃, the magnetic field thermal attenuation is minimal.

2. Both ends of the coil are wrapped with iron armor, which improves the utilization rate of magnetic energy, so that the magnetic field strength of the selection is increased by more than 8%, and the background magnetic field is more than 1.4T.

3. The coil shell is fully sealed, rain, dust and corrosion proof, to ensure that the equipment can work in a variety of harsh environments.

4. The use of unloading water cooling transformer oil, no additional use of cooling water, energy saving, environmental protection, saving water resources.

5. The magnetic medium adopts the rod medium structure of different cross sections, the magnetic field gradient is large, the field strength is high.

6. With advanced fault diagnosis system and remote control system, the intelligent operation control of the equipment is realized.

7. According to the characteristics of different materials, can be selected gas-water composite ore flushing and pulsation device, with high mining efficiency, good sorting effect, water saving and other characteristics.

Main technical parameters

| model | LHGC-1000 | LKGC-1250F | LHGC-1500F | LHGC-1750F | LHGC-200F | UKGC-2250F | LHGC-2500F | UHGC-2750F | LHGC-3000F | LHGC-3600F | LHGC-4000F | LHGC-500F |

| Rated background field strength (T) | 1.1/1.44(0.6) Constant current, continuously adjustable | |||||||||||

| Medium induced magnetic field | 2.0/2.4(1.1) Constant current, continuously adjustable | |||||||||||

| Rated excitation power (kW) | ≤17/28(10) | ≤19/38(12) | ≤27/48(15.5) | ≤37/58(23) | ≤42/70(29) | ≤51/73(32) | ≤57/76(37) | <70/100(42) | ≤74/10B(48) | 90/115(50) | 98/128(58) | 120/138(75) |

| Dry ore processing capacity lt/h) | 2-3,5 | 5-9 | 10-15 | 15-25 | 25-40 | 40-60 | 50-75 | 50-100 | 75-125 | 125-200 | 175-275 | 300-400 |

| Slurry throughput capacity (m ³/h) | 12.5~20 | 20~50 | 50~100 | 75~150 | 100~200 | 160~300 | 200~400 | 200~500 | 350~650 | 550~950 | 750~1400 | 1400~2000 |

| Excitation current (A) | 85/85(70) | 85/100(85) | 110/140(110) | 125/170(1251 | 130/170(130) | 146/175(120) | 195/192(90) | 130/205(100) | 175/250(140) | 210/250(180) | 310/345(2051 | 320/365(200) |

| Mineral concentration (%) | 10-35 | |||||||||||

| Feed particle size (mm) | -1.2 | |||||||||||

| Rotating speed (r/min) | 2~4 | |||||||||||

| Outer diameter of swivel ring (m) | 1000 | 1250 | 1500 | 1750 | 2000 | 2250 | 2500 | 2750 | 3000 | 3600 | 4000 | 5000 |

| Rotary motor power (kw) | 1.1 | 15 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | 37 | 55 |

| Excitation Voltage (DCVI) | 0~514(Change with current) | |||||||||||

| Unloading water pressure (Mpn) | 0.2-0,4 | |||||||||||

| Unloading water consumption Im ³/h) | 8-12 | 12-20 | 20-30 | 30-50 | 40-80 | 60-100 | 80-120 | 100-150 | 120-220 | 150-250 | 200-400 | 350-550 |

| Host weight (t) | 9,5/13(7) | 13/22(11) | 21/31(20) | 32/42(28) | 45/60(39) | 65/72(62) | 98/120(80) | 130/150(95) | 165/185(138) | 275/310(230) | 375/400(315) | 498/528(430) |

| Maximum weight (t) | 2.3/3.342) | 4/6(3.5) | 9/744) | 13/15(9) | 16/20(13) | 24/28(16) | 25/32(18) | 26/33(19) | 28/35(191 | 32/36(28) | 35/35(28) | 35/35(30) |

| Dimensions (length x straight x height mm) | 2000×2340×2400 2100×2470×2400 | 2500×2340x3200 2600×3400×3010 | 2720×3120x3300 3640×3700×3200 | 3300×3650×3760 3300×4270×4073 | 3405×3800×4000 3780×4400×4400 | 4460x4700×4800 4460x4700×4880 | 4250x4830×5400 4450×5400×5300 | 4400x5510x5920 4620x5600x6200 | 4500×580×6450 4750×630×6800 | 5500x6500x7660 5800×6800×7860 | 6000×7200×6450 6200×7500×6650 | 7100×7650x9500 7550×8000×9570 |

| Round and simple sieve matching type | YTS-810 YTS-1210 | YTS-810 YT5-1210 | YTS-810 YT5-1210 | YTS-1415 YTS-2019 | YTS-1415 YTS-2019 | YT5-2019 YT5-2529 | YTS-2019 YTS-2529 | YTS-2529 | YTS-2529 | YTS-2529 | YTS-2529 | YTS-2529 |

Note: 1. This data is for reference only. The blue word is the corresponding parameter of 1.4T high-intensity magnetic field magnetic separator, and the red word is the corresponding parameter of 0.6T medium-intensity magnetic field

magnetic separator.