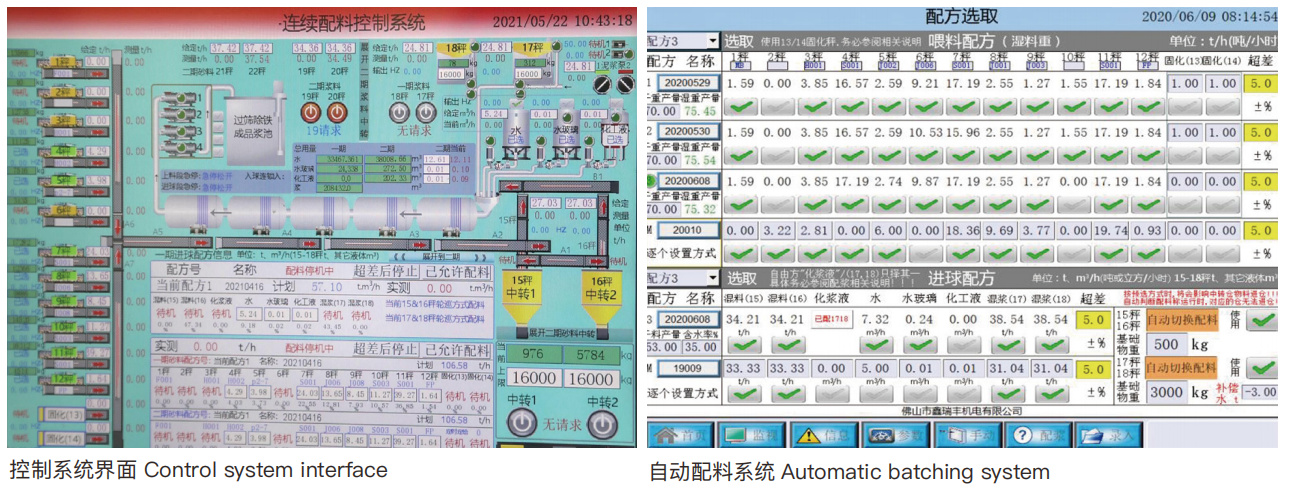

Intelligent Raw Material Batching System

product video

Product display

Product Introduction

Intelligent batching system includes ridge batching system and plastic batching system:

1. The ridge material batching system is composed of multiple feeding units, which are uniformly intelligent controlled by the control system; The feed machine is equipped with sensors, which can feed back the weight of the raw material in the feed machine to the control system, which controls the supply by controlling the speed of the conveyor belt of the feed machine; The feeding machine is loaded with different raw materials, which can be controlled by the central control system with simple one-key. As long as the formula is input in the control terminal, the system can automatically control the amount of each raw material according to the input data; A variety of formulas can be stored in the control system. When the formula needs to be changed, it can be quickly mixed according to the new formula by simple operation in the control terminal.

2. Plastic material batching system: the slurry of the slurry pool is transported to the slurry transfer cylinder in front of the continuous ball through the slurry pump, and then transported to the continuous ball mill by the quantitative pump according to the process requirements.

Main technical parameters

| 4.Comparison of energy consumption among three ball milling methods | |||

| 60T Intermittent ball mill process | Semi-continuous ball milling process | Fullcontinuous ball milling process | |

| Power consumption | 34.55 kW.h | 29.17 kW.h | 25.06 KW.h |

| Power saving rate% | (34.55-28.87)/34.55=15.57% | (34.55-25.06)/34.55=27.5% | |