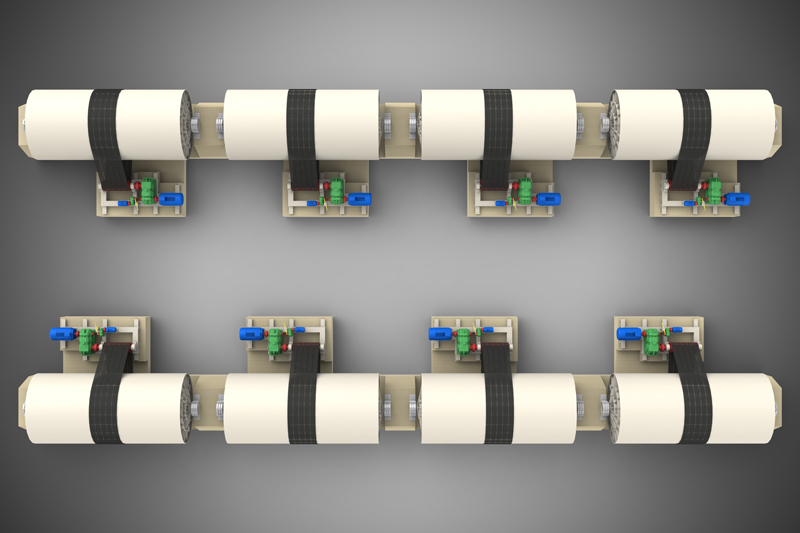

Energy-Saving And High Efficiency Grinding Ceramic Powder Ball Mill Machine

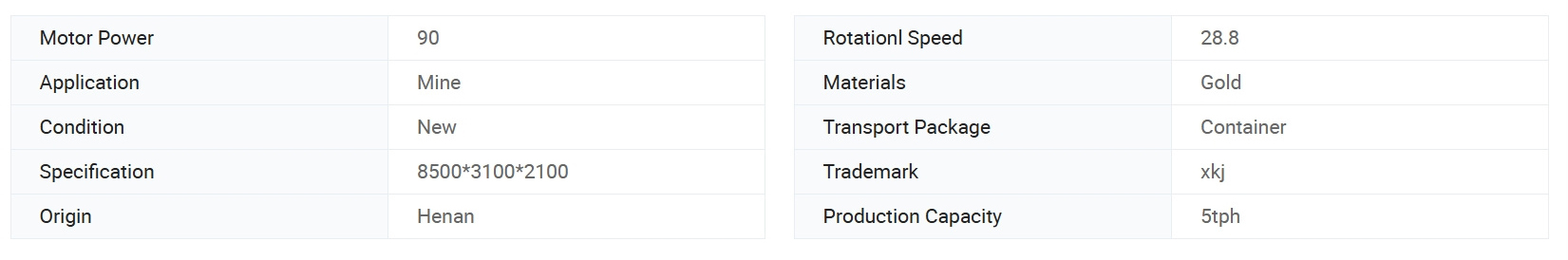

Basic Info.

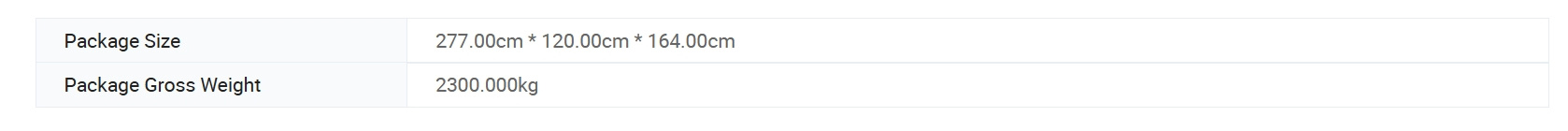

Packaging & Delivery

Product Video

Product Features

1. The cylinder is rolled using a new CNC rolling machine, which produces a cylinder with good ovality and no straight edges;

2. The cylinder adopts vertical splicing to ensure good coaxiality and straightness of the cylinder;

3. The belt position of the cylinder and the bearing positions at both ends are processed using a large floor mounted lathe, ensuring good coaxiality and ovality, ensuring stable equipment operation, low current fluctuations, and energy conservation;

4. After welding the two end heads, annealing treatment is carried out in a large annealing furnace to eliminate welding stress and ensure service life;

5. Non-destructive testing of shaft head, normalizing treatment after rough car, eliminate forging stress, better strength, ensure service life;

6. The hard tooth reducer scheme can be adopted, which has high transmission efficiency, low noise, and saves energy consumption; Equipped with exclusive adjustment technology for gearbox bearing clearance (patent number: 201020685450.6), the service life is longer.

Protective lining plate:

1. High wear-resistant protection plate

2. Choice of lining material (Mn steel casting lining plate / rubber lining plate)

3. Manganese steel lining plate material: Hi-Mn13 alloy casting

4. Rubber lining plate material: butyl super wear resistant rubber

Main technical parameters

| Main parameters of standard ball mill series products | |||||||||

| Serial Number | model | tonnage | (L) capacity | (mm) Cylinder size | kW Main motor power | Maximum usage conditions | start mode | notes | |

| lining | lining | ||||||||

| 1 | Q0607 | 0.05 | 200 | Ø600x700(594x688) Minouchi | 1.5-6 | high alumina | high alumina | direct | |

| 2 | Q0709 | 0.1 | 330 | ø7001900(694x888) Minouchi | 2.2-6 | high alumina | high alumina | direct | |

| 3 | Q0911 | 0.2 | 680 | Ø900x1100(894x1084) Minouchi | 3-6 | high alumina | high alumina | direct | |

| 4 | Q1113 | 0.3 | 1200 | Ø1100x1300(1092x1280) Minouchi | 4-6 | high alumina | high alumina | direct | |

| 5 | Q1315 | 0.5 | 2000 | Ø1300x1500(1290x1480) Minouchi | 5.5-6 | high alumina | high alumina | direct | |

| 6 | Q1618 | 1 | 3500 | Ø1600x1800(1588x1776) Minouchi | 11-6 | high alumina | high alumina | direct | |

| 7 | Q1820 | 1.5 | 5000 | Ø1800x2000(1788x1972) Minouchi | 15-6 | high alumina | high alumina | direct | |

| 8 | Q1920 | 2 | 5320 | Ø1900x2000(1888x1902) Minouchi | 18.5-6 | high alumina | high alumina | direct | |

| 9 | Q2124D | 3 | 7700 | Q2100×2400(2084×2258) Minouchi | 30-6 | high alumina | high alumina | Frequency conversion | |

| 10 | Q2426A | 5 | 10700 | Ø2400x2600(2380×2394) Minouchi | 37-6 | high alumina | high alumina | Frequency conversion | |

| 11 | Q2426C | 5 | 10700 | Ø2400x2600(2380x23) Minouchi | 45-6 | high alumina | high alumina | Frequency conversion | |

| 12 | Q2628 | 6 | 13800 | Ø2600×2800(2580×2594) Minouchi | 45-6 | high alumina | high alumina | Frequency conversion | |

| 13 | Q2628A | 6 | 13800 | Ø2600x2800(2580×2594) Minouchi | 45-6 | high alumina | high alumina | Frequency conversion | |

| 14 | Q2832 | 8 | 18200 | Ø2800x3200(2780×2990) Minouchi | 55-6 | Chalco | Chalco | Frequency conversion | |

| 15 | Q3038 | 10 | 24550 | Ø3000x3800(2976x3530) Minouchi | 55-6 | Chalco | Chalco | Frequency conversion | |

| 16 | QJ3246 QT3246A | 15 | 34000 | Ø3200x4600(3172x4278) Minouchi | 90-4 | high alumina | high alumina | Frequency conversion | |

| 17 | Q3244T | 15 | 32000 | Ø3200x4400(3168x4076) Minouchi | 280-6 | high alumina | high alumina | Frequency conversion | Belt position double layer |

| 18 | Q3352 | 20 | 41200 | Ø3300x5225(3272x4908) Minouchi | 90-8 | Chalco | Chalco | Frequency conversion | |

| 19 | QJ3352 QJ3352A | 20 | 41200 | Ø3300×5225(3272x4908) Minouchi | 110-4 | high alumina | high alumina | Frequency conversion | |

| 20 | Q3358 | 25 | 45000 | Ø3300x5800(3268x5336) Minouchi | 90-8 | Chalco | Chalco | Frequency conversion | |

| 21 | QJ3358 QJ3358A | 25 | 45000 | Ø3300x5800(3268x5336) Minouchi | 132-4 | high alumina | high alumina | Frequency conversion | |

| 22 | QJ3564 QJ3564A | 35 | 58000 | Ø3532x6468(3500x6000) Minouchi | 160-4 | high alumina | high alumina | Frequency conversion | |

| 23 | Q3672 | 40 | 67000 | Ø3600x7200(3564x6700) Minouchi | 160-6 | Chalco | Chalco | Frequency conversion | belt drive |

| 24 | QJ3672 | 40 | 67000 | Ø3600x7200(3564x6700) Minouchi | 200-4 | Chalco | Chalco | Frequency conversion | ZLY400 |

| 25 | QJ3672T | 40 | 67000 | Ø3600×7200(3564x6700) Minouchi | 250-6 | high alumina | high alumina | Frequency conversion | ZLY450 |

| 26 | QJ3875 | 50 | 85000 | Ø3836x8000(3800x7500) Minouchi | 200-4 | high alumina | high alumina | Frequency conversion | |

| 27 | QJ4086 | 60 | 100000 | Ø4000x8600(3964x8000) Minouchi | 280-6 | Chalco | Chalco | Frequency conversion | ZLY450 |

| 28 | QJ4086T | 60 | 100000 | Ø4000x8600(3964x8000) Minouchi | 315-6 | Chalco | Chalco | Frequency conversion | ZLY500 |

| 29 | QJ4290 | 80 | 114100 | Ø4248x9000(4200*8400) Minouchi | 315/355-6 | high alumina | high alumina | Frequency conversion | ZLY500/ZLY560 |

| 30 | QJ42110 | 100 | 144300 | Ø4256x11000(4200*10400) Minouchi | 355/400-6 | high alumina | high alumina | Frequency conversion | ZLY560 |

| 31 | QJ42122 | 120 | 160700 | Ø4256x12200(4200*11600) Minouchi | 450/500-6 | high alumina | high alumina | Frequency conversion | ZLY560 |