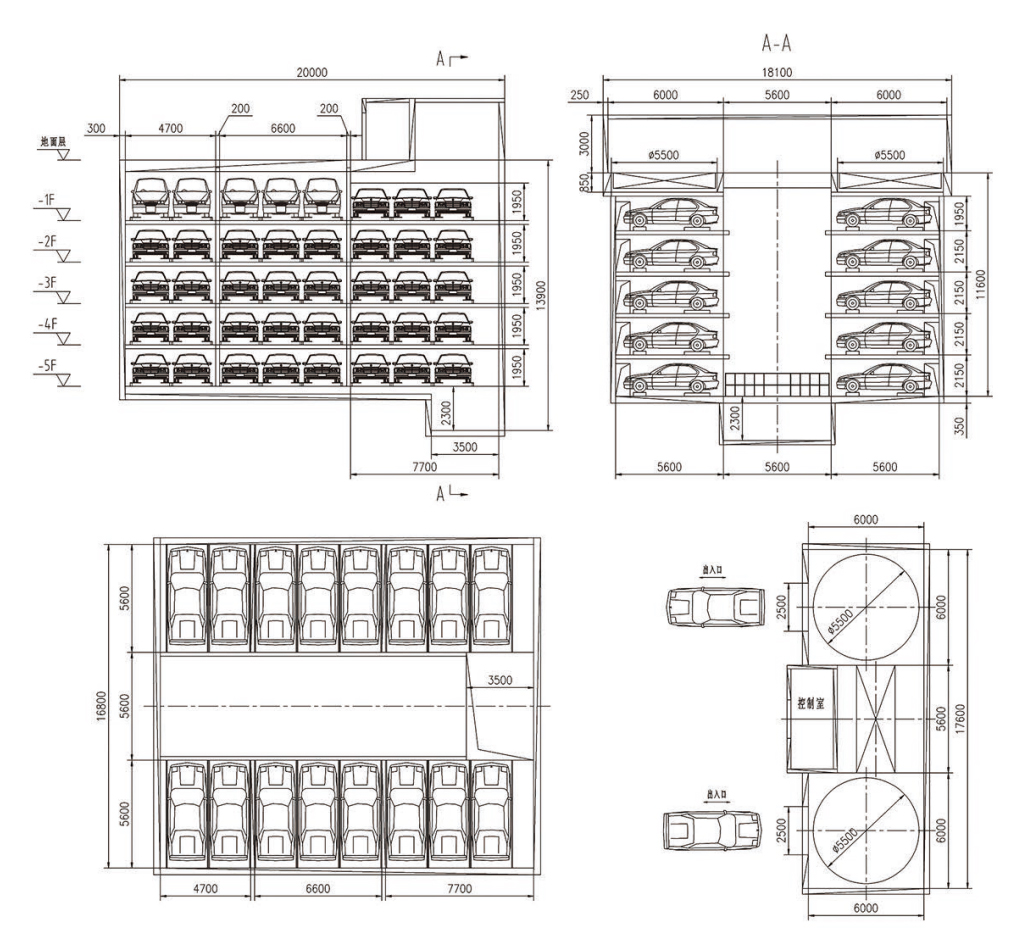

Flat Mobile Stereo Garage

Technical features of the equipment

◆The intelligent transporter supports re-row parking spaces, and the equipment requires a small lane space and a small clearance height requirement for the parking space, which is ahead of the peer level.

◆The equipment cooperates perfectly and moves in coordination to save time for parking and retrieval. The storage and retrieval time of a single car is 60~120 seconds, and the continuous storage and retrieval time is no more than 90 seconds per car on average, with a high degree of automation and high operating efficiency.

◆It has multiple safety protection measures to ensure the safety of people and vehicles.

◆Easy to operate. Customers with fixed parking spaces can swipe their cards to operate; customers with temporary parking spaces are guided by the administrator to store and retrieve cars.

◆When parking and retrieving cars, the vehicles are moving forward, without reversing or turning around, which is convenient for car owners.

Fully enclosed construction ensures the safety and cleanliness of the vehicles.

◆Fully automatic operation, easy operation and control, and the operation and maintenance costs of the garage

◆Flexible system configuration. One or more translation vehicles can be arranged on each floor, or multiple floors can share a translation vehicle (changing floors through elevators). The former is suitable for garages with frequent car storage and retrieval, while the latter is suitable for garages with infrequent car storage and retrieval and short lanes, which is convenient for reducing construction costs.

◆High space utilization and wide application range. The number of garage floors can range from 2 to 12, and the location can be set above ground, underground or semi-underground.

Design parameters

|

Number of floors |

2-6 |

||

|

Car size (length x width x height) |

5300mm×1950mm×1550/2050mm |

||

|

Car weight (kg) |

≤2350 |

||

|

Operation method |

Automatic/Manual |

||

|

Running speed |

Lifting |

30-90m/min |

|

|

Transverse movement |

40-100m/min |

||

|

Storage and retrieval |

25m/min |

||

|

Rotation |

4rpm |

||

|

Motor power |

Lifting |

22-37kw |

|

|

Transverse movement |

2.2-4kw |

||

|

Storage and retrieval |

1.5kw+0.5kw |

||

|

Rotation |

1.5kw |

||

|

Power supply |

AC 380V/50Hz |

||

|

control |

Frequency conversion PLC logic automatic control |

||

|

Safety devices |

●Emergency stop device | ●Transverse over-limit protection device | |

| ●Up and down limit protection device | ●Up and down positioning switch | ||

| ●Operation limit device | ●Current overload protection device | ||

| ●Wheel stop bar | ●Anti-overlap automatic detection device | ||

| ●Anti-fall device | ●Length, width and height detection | ||

| ●Transverse positioning switch | ●Operation warning device | ||

| ●Power-off brake device | ●Automatic door anti-pinch device | ||