Du Rubber Belt Vacuum Filter

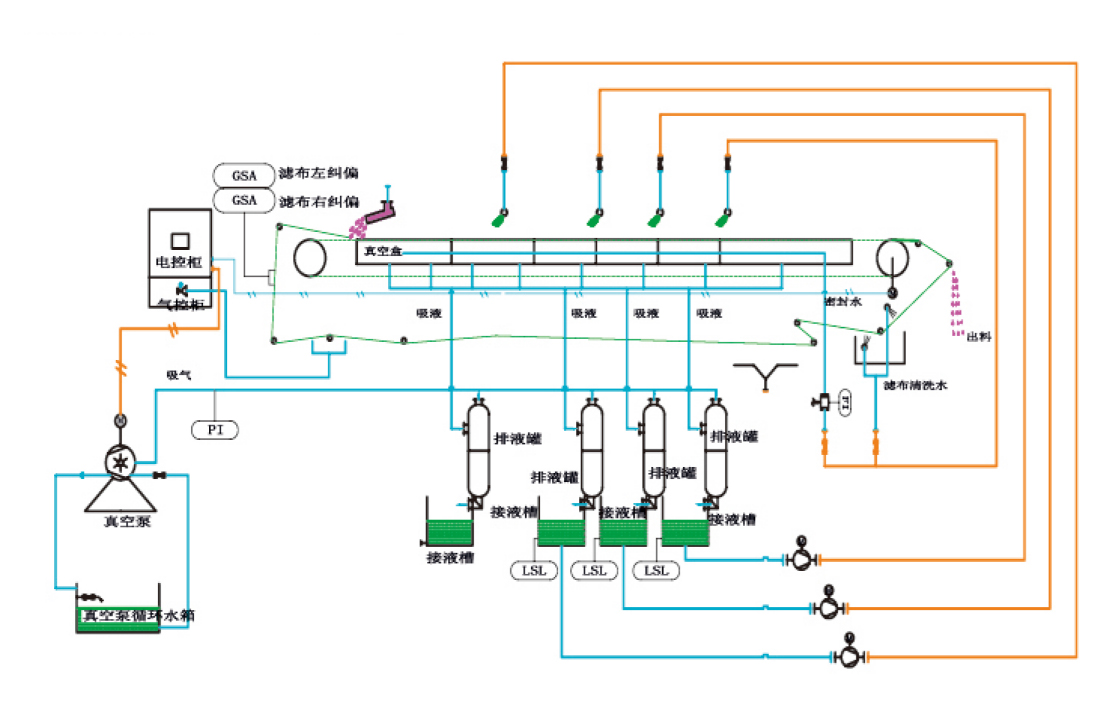

Working principle

The rubber belt vacuum filter adopts a fixed vacuum box, and realizes solid-liquid separation equipment with vacuum negative pressure as the driving force. It is a new type of solid-liquid separation equipment with high efficiency and continuous operation. The tape slides on the vacuum box, and the structure of the motion seal is formed between the vacuum box and the tape. It can continuously and automatically complete filtration, filter cake washing, slag unloading, filter cloth regeneration and other process operations, and the mother liquid and filter cake washing liquid can be collected in stages. It has the advantages of high filtration efficiency, large production capacity, good washing efficiency, low water content of filter cake, flexible operation and simple maintenance. After years of improvement and improvement, the technical performance and quality of the products have reached the international advanced level, and have been widely used in metallurgy, mining chemical industry, power plant wet flue gas desulfurization, coal chemical industry, paper making, food, pharmaceutical and environmental protection industries.

Process flow

Desulfurization process

Main technical parameters

| series | Filter area (m²) | Effective width (m) | Effective length (m) | Fuselage width (m) | Fuselage width (m) | Fuselage height (m) | Fuselage Weight (t) | Vacuumconsumption (m³/min) |

| 500 | 3 | 500 | 6000 | 10200 | 1250 | 2070 | 4.6 | 12 |

| 4 | 80000 | 12200 | 4.9 | 14 | ||||

| 5 | 10000 | 14200 | 5.7 | 16 | ||||

| 6 | 12000 | 16200 | 6 | 20 | ||||

| 600 | 4.8 | 600 | 8000 | 12200 | 1350 | 2070 | 5.1 | 16 |

| 6 | 10000 | 14200 | 6.2 | 20 | ||||

| 7.2 | 12000 | 16200 | 6.8 | 22 | ||||

| 84 | 14000 | 18200 | 7.3 | 26 | ||||

| 1000 | 8 | 1000 | 8000 | 12200 | 1750 | 2070 | 7.1 | 26 |

| 10 | 10000 | 14200 | 7.5 | 28 | ||||

| 12 | 12000 | 16200 | 8.4 | 30 | ||||

| 14 | 14000 | 18200 | 9.1 | 32 | ||||

| 1300 | 10.4 | 1300 | 80000 | 12200 | 2050 | 2070 | 7.7 | 28 |

| 13 | 10000 | 14200 | 8.5 | 30 | ||||

| 15.6 | 12000 | 16200 | 9.3 | 35 | ||||

| 18.2 | 14000 | 18200 | 9.9 | 38 | ||||

| 20.8 | 16000 | 20200 | 11.5 | 40 | ||||

| 1500 | 13 | 1500 | 8600 | 12800 | 2250 | 2120 | 8.3 | 28 |

| 15 | 10000 | 14200 | 9.1 | 30 | ||||

| 18 | 12000 | 16200 | 10.1 | 36 | ||||

| 20 | 13300 | 17500 | 11.9 | 40 | ||||

| 24 | 16000 | 20200 | 14.8 | 45 | ||||

| 1800 | 144 | 1800 | 8000 | 12200 | 2550 | 2170 | 9.4 | 32 |

| 18 | 10000 | 14200 | 10.8 | 38 | ||||

| 21.6 | 1000 | 16200 | 12.6 | 40 | ||||

| 25.2 | 14000 | 18200 | 15.7 | 45 | ||||

| 30.6 | 16000 | 20200 | 17.2 | 50 | ||||

| 32.4 | 18000 | 2200 | 18.5 | 55 | ||||

| 2000 | 20 | 2000 | 10000 | 14200 | 2750 | 2170 | 12.9 | 38 |

| 24 | 12000 | 16200 | 14.7 | 42 | ||||

| 28 | 14000 | 18200 | 164 | 46 | ||||

| 32 | 16000 | 20200 | 18.5 | 50 | ||||

| 2500 | 20 | 2500 | 8000 | 12200 | 3250 | 2270 | 11.9 | 40 |

| 25 | 10000 | 14200 | 15.9 | 45 | ||||

| 30 | 12000 | 16200 | 17.8 | 50 | ||||

| 35 | 14000 | 18200 | 19.9 | 55 | ||||

| 40 | 16000 | 20200 | 22.3 | 60 | ||||

| 3000 | 30 | 3000 | 10000 | 14300 | 3750 | 2270 | 17.6 | 50 |

| 36 | 12000 | 16300 | 19.7 | 55 | ||||

| 42 | 14000 | 18300 | 23.1 | 60 | ||||

| 3500 | 35 | 3500 | 10000 | 14300 | 4250 | 2470 | 20.7 | 55 |

| 42 | 12000 | 16300 | 23.5 | 62 | ||||

| 49 | 14000 | 18300 | 29.7 | 70 | ||||

| 4000 | 48 | 4000 | 12000 | 16400 | 4800 | 2470 | 32.6 | 70 |

| 56 | 14000 | 18400 | 37.7 | 82 | ||||

| 64 | 16000 | 20400 | 41.5 | 95 | ||||

| 72 | 180000 | 22600 | 62 | 120 | ||||

| 4500 | 50 | 4500 | 11000 | 15500 | 5350 | 2600 | 33.9 | 70 |

| 54 | 12000 | 16500 | 36.6 | 82 | ||||

| 60 | 13000 | 17500 | 40.3 | 95 | ||||

| 72 | 16000 | 20600 | 60.8 | 120 | ||||

| 81 | 18000 | 22600 | 66 | 125 |