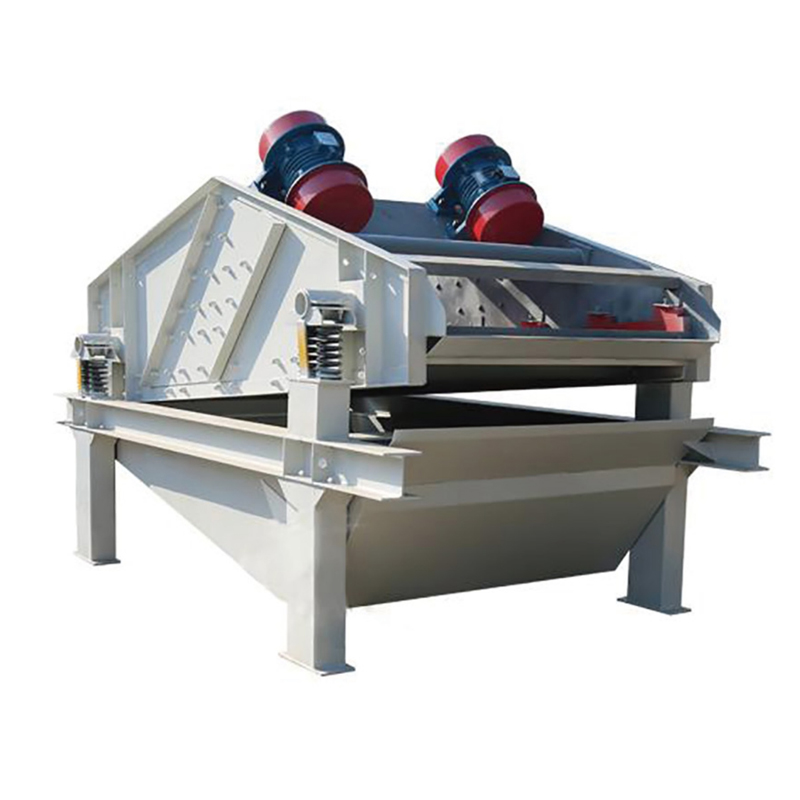

Dewatering Screen for Mineral Processing

Product features

1. The screen material is made of polymer polyurethane (UHMW-PE), which is resistant to impact, low temperature, wear and

chemical corrosion;

2. Vibration motor is easy to replace.Rubber spring of base is used for shock absorption,so that its amplitude is small.Slow vibration,the material can be removed cleanly:

3. Can be customized according to output and water content. Side plate of the body has a reinforcing plate,Equipped bar in the

bottom.and outiet is supported by triangular steel plate,which is thick;

4. Vibration motor is fixed with high-strength bolts.Bottom affect the life of vibration motor.Sieve plate has a high fixed densityand stiffenexs in it.

Screen structure (preparation, punching, seam), mesh size, processing capacity, material granularity.

Main technical parameters

| Model | (m²) Scraen area | (kW) Power | (m/h) Capacity | (mm) Feed particeSize | (t) Weight | (mm) Dimension |

| SYTS-0820 | 1.5 | 0.75×2 | 5-10 | 10 | 0.8 | 2300x1000x750 |

| SYTS-0920 | 1.8 | 1.1x2 | 10-20 | 10 | 1.2 | 2300x1200x750 |

| SYTS-1020 | 2.0 | 1.5x2 | 20-30 | 10 | 1.6 | 2300x1300x750 |

| SYTS-1225 | 3.0 | 2.2×2 | 50-80 | 10 | 2.1 | 2300x1500x750 |

| SYTS-1530 | 4.5 | 3.0x2 | 100-120 | 10 | 3.2 | 2300x1800x750 |