Bentonite Crushers: Leading Manufacturers & Exporters from China - Top Quality Equipment

If you need a reliable solution for handling bentonite, our advanced Crushers for Bentonite are expertly designed to meet the unique properties of this material, ensuring optimal performance and durability. We source our equipment from leading manufacturers in China, maintaining high standards of quality that align with international benchmarks. With years of experience, we focus on understanding client needs and delivering solutions that boost productivity and efficiency. At Fujian Minjie Machinery Co., Ltd., you will find competitive pricing coupled with exceptional customer service. Our crushers are built for longevity and can be tailored to fit your specific operational requirements, helping you achieve your production goals. Contact us today to discuss how our machinery can enhance your business operations.Expert Choice of Crusher For Bentonite Application Guarantees Peak Performance

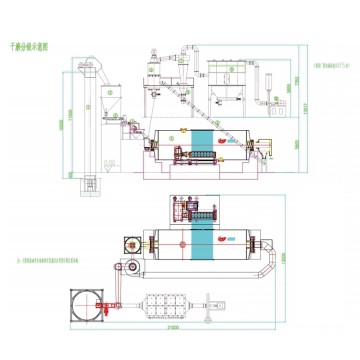

When it comes to processing bentonite, selecting the right crusher is critical to achieving peak performance. Bentonite, known for its unique properties, is widely utilized in various industries, including ceramics, drilling, and environmental applications. However, to maximize its benefits, the crushing process must be finely tuned. A crusher specifically designed for bentonite can ensure the preservation of its natural characteristics while achieving the desired particle size and uniformity. With over three decades of experience in ceramic machinery development, the expertise in the design and manufacturing of crushers tailored for bentonite applications is unparalleled. These machines are engineered to handle the unique challenges posed by bentonite, such as its plasticity and varying moisture levels. By employing advanced technology and robust materials, the ideal crushers deliver not only efficiency but also durability, ensuring longevity in demanding operational environments. For global buyers, investing in a high-quality crusher for bentonite processing translates to enhanced productivity and reduced operational costs. The right choice of machinery can significantly impact the quality of the final product, making it essential for companies to partner with manufacturers that prioritize innovation and precision. Trusting seasoned professionals in the field guarantees that your operations will remain competitive, meeting market demands effectively while providing consistent results.

Expert Choice of Crusher For Bentonite Application Guarantees Peak Performance

| Crusher Type | Max Output (TPH) | Power (kW) | Bentonite Condition | Operating Cost ($/ton) |

|---|---|---|---|---|

| Jaw Crusher | 50 | 75 | Moist | 10 |

| Cone Crusher | 70 | 100 | Dry | 12 |

| Impact Crusher | 60 | 90 | Mixed | 11 |

| Roller Crusher | 30 | 55 | Wet | 9 |

| Hammer Crusher | 45 | 70 | Fines | 8 |

Pinpointing Crusher For Bentonite Factory Your Trusted OEM Partner

A

Alexander Scott

The product quality is remarkable, and I appreciate the excellent after-sales support!

25 May 2025

C

Chloe Green

Fast delivery and top-tier product quality. The service team was extremely helpful.

08 June 2025

E

Evelyn Mitchell

Superb product and impeccable service. This company truly knows how to treat its customers!

04 July 2025

J

Jacob Stewart

Outstanding craftsmanship! Coupled with impressive customer service—highly recommend!

28 May 2025

O

Owen Cooper

The product speaks for itself! Excellent follow-up by the customer service team.

05 July 2025

L

Leo Sanders

The quality is really impressive! The follow-up support was also commendable.

06 June 2025