Crusher Equipment Case For Glass & Ceramics Industry

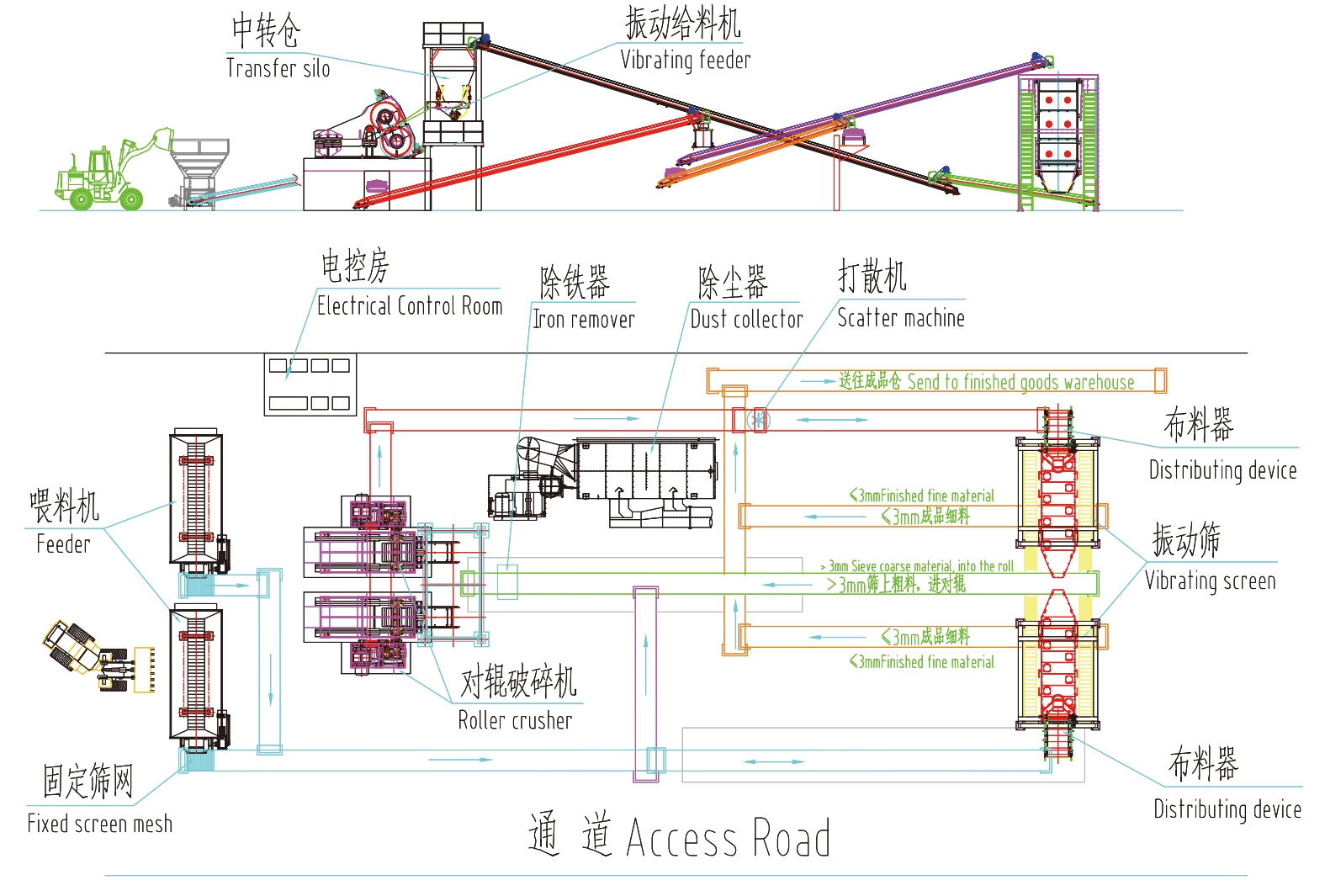

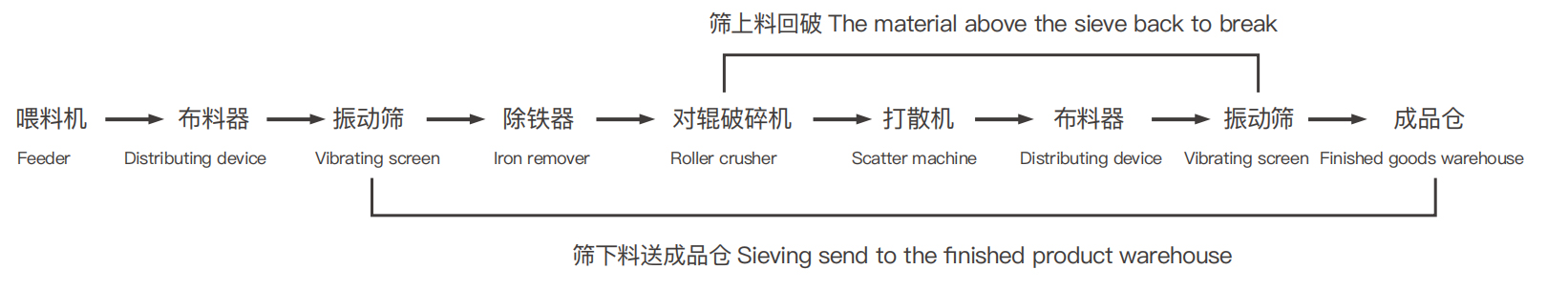

Crushing system diagram

Crushing process description

Main parameters of crushing field

1. Crushing raw materials are ball mill raw materials, sodium-potassium feldspar;

2, crushing parameters: raw material particle ≤20mm, water content ≤10%, Mohs hardness < 7.0;

3. Crushing and discharging parameters: finished particles ≤3mm;

4. production capacity: 150~160T/h.

| Energy saving calculation(60T ball mill,daily powder 1000T,annual output 300 days) | |||

| Annual cost of saving 2 hours of ball milling time | |||

| Powder per day.t | 1000 | Single ball loading.t | 68 |

| Running current.A | 300 | Milling time saving.h | 2 |

| Unit price of electricity.Rmb/kW.h | 0.65 | Ball milling saves electricity.kW.h | 335.66 |

| Save electricity..Rmb | 218.18 | Powder saves electricity.Rmb/t | 3.21 |

| Pebble loss.Rmb/t | 0.85 | Ball stone saving.Rmb/t | 1.7 |

| Cost savings per day.Rmb | 4910 | Annual cost savings.Ten thousand Rmb | 147.3 |

| Increase the annual cost of slurry | |||

| Slurry ratio.% | 50% | Annual crushing amount.Ten thousand tons | 15 |

| Power consumption of slurry.kW.h/t | 1.8 | Transmission power consumption.kW.h/t | 0.7 |

| Unit price of slurry electricity.Rmb/kW.h | 0.3 | Annual broken electricity charge.Ten thousand Rmb | 11.25 |

| Loss of slurry.Rmb/t | 0.55 | Annual cost of breakage and loss.Ten thousand Rmb | 8.25 |

| Daily crushing cost.Rmb | 650 | Annual total cost .Ten thousand Rmb | 19.5 |

| Increase the cost of annual crushing recovery.Ten thousand Rmb | 127.8 | ||