Continuous Ultrafine Grinding For Zirconium Silicate

Product advantage

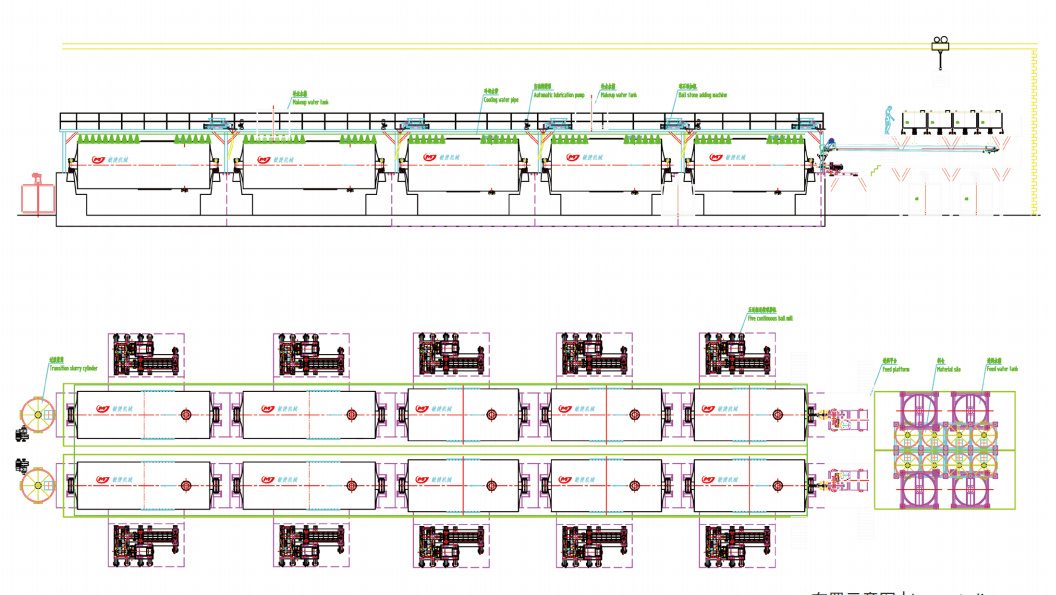

Layout diagram

1, grinding fineness up to 10000 mesh, uniform particle size distribution, stable and reliable quality.

2,There is no phenomenon in continuous zirconium silicate ultrafine pulping ball mill, there will be no spraying injury, there is no need to manually discharge the pulp, which greatly improves the operation safety of workers.

3, save energy, while reducing the total grinding time to improve the grinding efficiency, the customer's actual use data shows that compared with the traditional intermittent ball mill energy saving 9.8%.

4, the feed transfer cylinder through the accurate weight reduction measurement method by the computer program according to the formula to control the feed, to solve the problem of raw material formula feed control.

5, The intermediate pulping device of the system adopts the transition mode developed independently to ensure that the intermediate pulping device will not leak pulp during long-term operation of the equipment, and can supplement the grinding medium and water at the same time.

6, continuous ball mill can contain 3 ~ 6 units with an independent drive system of the ball mill, each unit design has an independent speed and stone ratio, according to the raw material situation and the required powder fineness requirements, choose the appropriate stone ratio and speed, so as to achieve the highest efficiency.

7, intelligent control, greatly save labor, and reduce the labor intensity of workers, save the time of unloading.

Main technical parameters

| model | m ³ volume | m m Cylinder size | Type of lining | Grinding media |

| QCX2582 | 36.8 | φ2500×8200 | High alumina lining | Zirconium aluminum/high aluminum ball |

| QCX2590 | 40.6 | φ2500×9000 | High alumina lining | Zirconium aluminum/high aluminum ball |

| QCX2870 | 39 | φ2800×7000 | High alumina lining | Zirconium aluminum/high aluminum ball |

| QCX3084 | 54.6 | φ3000×8400 | High alumina lining | Zirconium aluminum/high aluminum ball |

| QCX3370 | 54.5 | φ3300×7000 | High alumina lining | Zirconium aluminum/high aluminum ball |

Note: Continuous ball mill combined use, can be adjusted according to customer output and fineness.

Key Features

Continuous Operation: Enables uninterrupted grinding and discharge, improving productivity and process stability.

Ultrafine Output: Capable of achieving particle sizes as fine as 1–5 microns, ideal for zirconium silicate’s application in high-performance ceramics and paints.

Precision Control: Adjustable grinding speed, media size, and residence time for tailored particle size distribution and quality control.

Low Contamination Design: Made with wear-resistant materials to preserve the high purity of zirconium silicate and prevent media or liner contamination.

Closed-Circuit Capability: Integrates seamlessly with classifiers or separators to achieve precise cut sizes and maintain narrow particle distribution.

Applications

Advanced Ceramics (e.g., dental ceramics, tiles)

Paints and Coatings

Refractories and Foundry Materials

Electronic Components

Abrasives and Fillers

Advantages

High product purity and whiteness

Energy-efficient and cost-effective continuous operation

Reduced downtime and minimal maintenance

Scalable design for various production capacities