Continuous Ball Mill for Ore Processing

product video

product details

product accessories

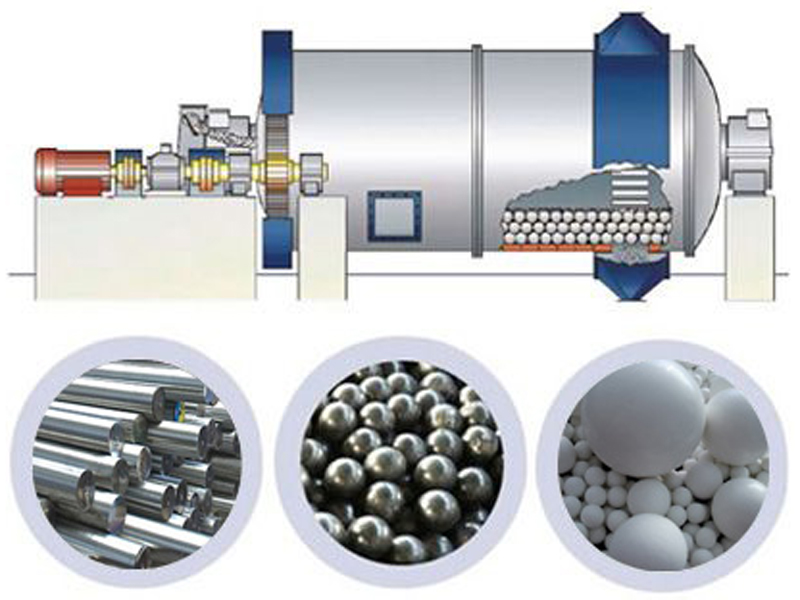

Ball Mill Accessories: Steel Balls & Liners

Steel balls and lining plates play a critical role in the efficient operation of a ball mill. Our high-quality steel balls are made from premium alloy steel and undergo strict heat treatment processes to ensure excellent wear resistance and impact toughness. They deliver consistent, high-efficiency grinding performance under continuous rotation.

The wear-resistant lining plates are crafted from high-manganese or high-chromium steel, effectively preventing direct abrasion between raw materials and the mill shell. This extends the service life of the equipment and reduces maintenance costs. Both components are precisely manufactured to ensure uniform size, stable hardness, and compatibility with a wide range of milling requirements.

Whether in ore processing, cement production, or industries like metallurgy and chemical engineering, reliable steel balls and liners are essential for stable operation, reduced energy consumption, and increased overall productivity. Our accessories are available in standard models and can also be customized in size, material, or structure to suit specific working conditions and production needs.

Choosing our ball mill accessories means investing in long-lasting durability, consistent performance, and optimized cost-efficiency. We are committed to delivering dependable components that keep your equipment running at peak efficiency, even under demanding, high-load conditions.

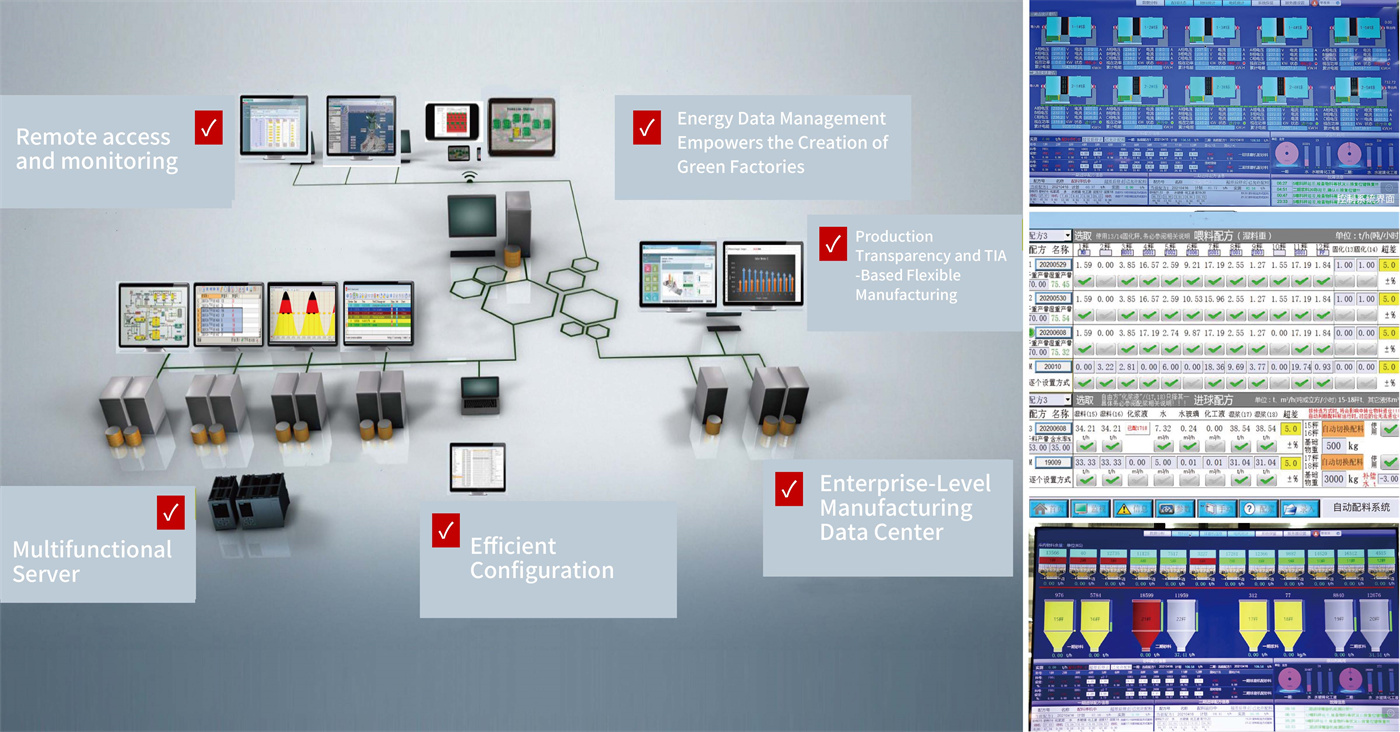

Raw Material System

The Raw Material System integrates web-based report publishing, remote monitoring and control, energy management, and production KPI tracking, enabling full digitalization of the raw material production process.

Real-time data visualization and automatic report distribution ensure faster decision-making and improved operational transparency. With remote monitoring and control, users can track equipment status and key process parameters anytime, anywhere—enhancing efficiency while reducing manual intervention.

The built-in energy management module provides accurate consumption data across each production stage, supporting cost reduction and sustainable operations. At the same time, the KPI dashboard gives a clear view of key metrics such as output, efficiency, and downtime, helping optimize production performance.

Powered by intelligent algorithms and automated control logic, this system lays the foundation for fully intelligent raw material production—driving smart manufacturing and digital transformation across the enterprise.

Process scheme

Full continuous ball mill process plan: The granular material and clay material are pre processed separately before entering the continuous ball mill.

(1)Description of gridge material goals:

1. The raw materials are crushed to 3mm and then transported to the standard warehouse by a forklift.

2. The bottom of the standard warehouse is equipped with a belt scale, which mixes the prepared materials through a drum screen and sends them to the transfer warehouse.

3. The transfer warehouse supplies materials to the continuous ball mill based on the output of the ball mill.

The appraisal technology has reached the international advanced level

Rotary pipe fluid overseal technology has reached the international leading level

(2) Slurry description:

1. According to the formula, the plastic material is transported from the feeder to the slurry continuous ball mill, and the appropriate amount of water differentiation, labor and plastic material is added according to the process design.

2. The slurry is continuously pelted out. After the slurry is sifted through the vibrating round screen, the iron is removed and then transported to the underground slurry pond for homogenization and waiting for use.

3. A filter cone bucket is designed at the pulp end of the slurry ball to screen out the impurities contained in the raw materials.

4. Vibrating round screen removes the sand particles contained in the slurry and sends them to the sand bin for unified treatment.

5. The slurry of the underground slurry tank is supplied to the continuous ball mill through the plunger pump according to the process design, according to the formula and the output.

Comparison of equipment energy consumption

Raw material particles 10-20mm, finished stock fineness 250 mesh screen size 0.8-1.0

| 1.power consumption per ton of powder | ||

| Intermittent ball mill | Intermittent ball mill | |

| Power consumption per mill | 160kW | 280kW |

| Average operating current | 210A | 300A |

| Fillng amount of raw materials | 48t | 68t |

| Ball milling time | Medium-high alumina nodules/pot | Medium-high alumina nodules |

| Power consumption per mill | 210Ax380Vx1.732×0.85x15h/1000=1762.2 kW.h | 300Ax380Vx1.732x0.85x14h/1000=2349.6 kW.h |

| Power consumption | 1762.2Kwh/48T=36.71 kW.h/t | 2349.6Kwh/68T=34.55 kW.h/t |

| 2.The intermittent ball ill combined with the three-piece continuous ballmill isa semi-continuous system of power consumption per ton of powder | ||

| Intermittent ball mill | Continuous ball mill | |

| power | 280kW | 355KWx3=1065kW |

| Average operating current | 320A | 280A |

| Filling amount of raw materials | 68t | 45t/h |

| Milling time | 7h/ pot | Continuous operation |

| Power consumption per mill | 320Ax380Vx1.732x0.85x7h/1000=1253.1kW.h/t | 280Ax380Vx1.732x0.85x3/1000=469.9 kW.h |

| Power consumption | 1253.1Kw.h/68T=18.43 kW.h/t | 469.9Kwh/45T=10.44kW.h/t |

| amount to | 18.43+10.43+0.3=29.17 kW.h/t Plunger pump | |

| 3.Full continuous ball mill power consumption per ton of powder including crushing and slurry | ||

| device | D G1400 :20mm - 3mm | 1.85 kW.h/t |

| Single continuous ball mill slurry | 162Ax380V×1.732x0.85/50/1000=1.81 kW.h/t | |

| Six continuous ball mill | 455Ax380Vx1.732×0.85x6/65T/1000=23.49 kW.h | |

| Plunger pump power consumption | 0.3 kW.h/t | |

| Calculate unit ton consumption based on barren material:plastic material=7:3 | 1.85×0.5+1.81×0.3+23.29+0.1=25.06 kW.h/t | |

| 4.Comparison of energy consumption among three ball milling methods | |||

| 60T Intermittent ball mill process | Semi-continuous ball milling process | Fullcontinuous ball milling process | |

| Power consumption | 34.55 kW.h | 29.17 kW.h | 25.06 KW.h |

| Power saving rate% | (34.55-28.87)/34.55=15.57% | (34.55-25.06)/34.55=27.5% | |