Conical Crusher for Mineral Processing

Product features

1. The structure is novel, unique, simple and reasonable, the operation is balanced, the operation cost is low, the cone crusher body is cast steel structure, and the reinforcement is set at the high stress point of the heavy load part. Cone crusher drive shaft is equipped with tapered roller bearings at both ends, the power drive is completed by heavy bevel gear, and the bearing seat adopts skeleton sealing ring to prevent oil leakage;

2. the cone crusher contains a hydraulic adjustment mechanism, easy to quickly adjust the size of the cone crusher discharge port;

3. The hydraulic cavity cleaning mechanism is the standard configuration of the cone crusher, which is completed by 8 cavity cleaning oil cylinders placed on the base plate of the body;

4. Cone crusher provides "spring type" over-iron release protection;

5. the cone crusher adopts a set of external lubrication system including oil pump, oil tank and pipeline. The crusher will automatically shut down when the oil temperature is too high or the oil flow rate is too slow.

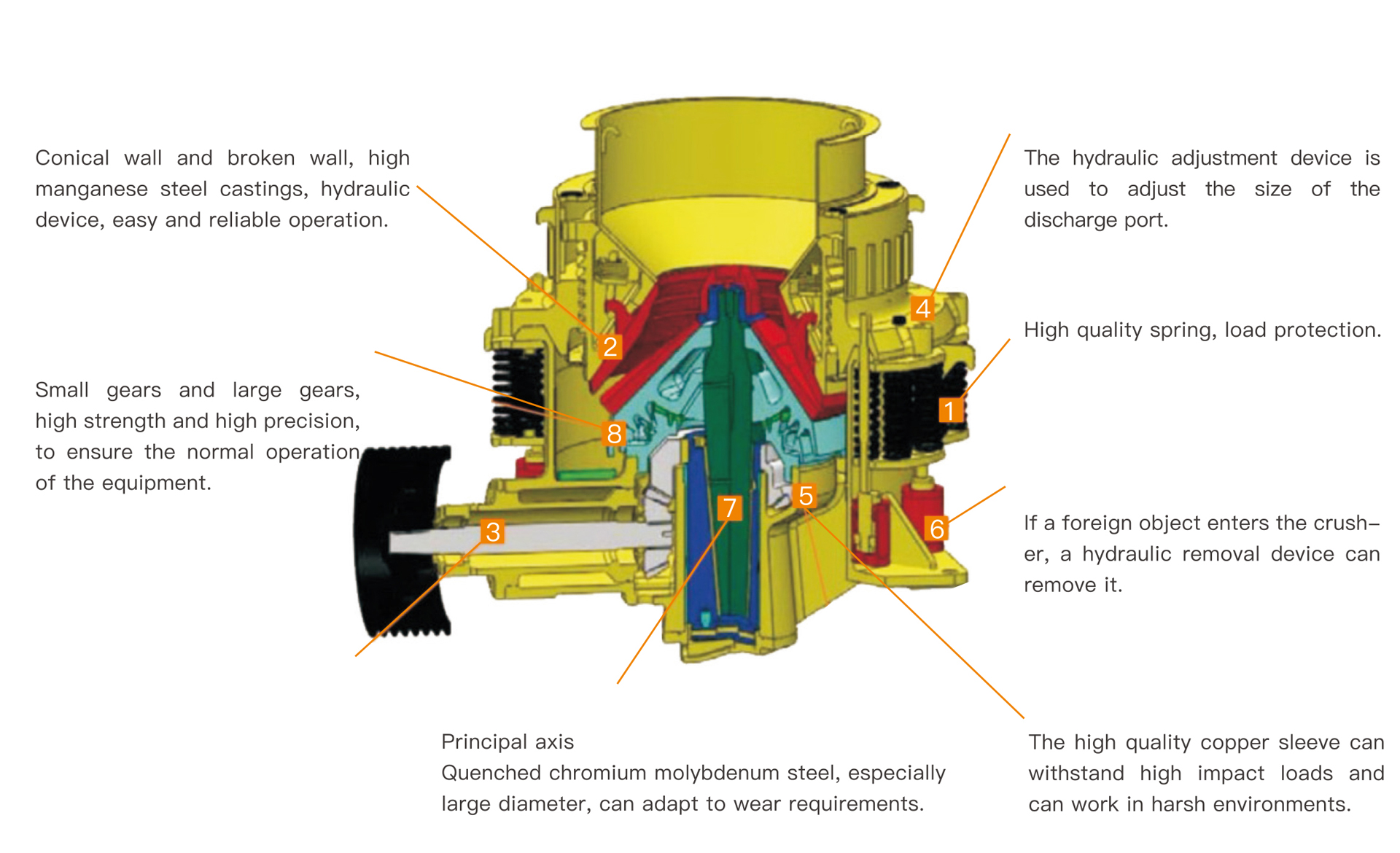

(1) High quality spring, load protection.

(2) Conical wall and broken wall, high manganese steel castings, hydraulic device, easy and reliable operation.

(4) The hydraulic adjustment device is used to adjust the size of the discharge port.

(5) The high quality copper sleeve can withstand high impact loads and can work in harsh environments.

(6) If a foreign object enters the crusher, a hydraulic removal device can remove it.

(7) Principal axis: Quenched chromium molybdenum steel, especially large diameter, can adapt to wear requirements.

(8) Small gears and large gears, high strength and high precision, to ensure the normal operation of the equipment.

Main technical parameters

| Model | Chamber | Crushing diameter | Max feed size (mm) | Min of discharge size (mm) | Weight (t) | Main motor power (kW) | Throughput | ||||||||||

| (inch) | (mm) | 6 | 10 | 13 | 16 | 19 | 22 | 25 | 38 | 51 | 64 | ||||||

| MPH1000 | C | 40" | 1016 | 160 | 13 | 10.8 | 90-110 | 70 | 90 | 125 | 135 | 160 | 215 | ||||

| M | 40" | 1016 | 115 | 10 | 10.8 | 90-110 | 55 | 65 | 70 | 90 | 120 | 135 | |||||

| F | 40" | 1016 | 80 | 8 | 10.8 | 90-110 | 47 | 50 | 60 | 67 | 90 | ||||||

| MPH1200 | C | 45" | 1143 | 180 | 13 | 16 | 110-132 | 105 | 120 | 35 | 160 | 180 | 220 | ||||

| M | 45" | 1143 | 130 | 10 | 16 | 110-132 | 72 | 92 | 105 | 35 | 150 | 170 | |||||

| F | 45" | 1143 | 90 | 10 | 16 | 110-132 | 70 | 90 | 100 | 125 | |||||||

| MPH1300 | C | 51" | 1296 | 200 | 16 | 23 | 132-160 | 135 | 160 | 180 | 200 | 290 | 350 | ||||

| M | 51" | 1296 | 150 | 13 | 23 | 132-160 | 105 | 125 | 135 | 160 | 180 | ||||||

| F | 51" | 1296 | 102 | 10 | 23 | 132-160 | 80 | 105 | 135 | 140 | |||||||

| MPH1400 | C | 54" | 1372 | 215 | 19 | 27 | 185-220 | 180 | 220 | 270 | 350 | 440 | |||||

| M | 54" | 1372 | 160 | 16 | 27 | 185-220 | 160 | 180 | 200 | 230 | |||||||

| F | 54" | 1372 | 115 | 13 | 27 | 185-220 | 150 | 195 | 220 | 240 | |||||||

| MPH1650 | C | 60" | 1524 | 235 | 22 | 37.8 | 220-250 | 230 | 265 | 330 | 450 | 520 | 570 | ||||

| M | 60" | 1524 | 175 | 19 | 37.8 | 220-250 | 215 | 240 | 270 | 330 | |||||||

| F | 60" | 1524 | 130 | 13 | 37.8 | 220-250 | 180 | 210 | 240 | 265 | 285 | ||||||

| MPH1950 | C | 68" | 1720 | 350 | 22 | 44.3 | 300 | 330 | 390 | 525 | 655 | 725 | |||||

| M | 68" | 1720 | 203 | 16 | 44.3 | 300 | 230 | 270 | 300 | 330 | |||||||

| F | 68" | 1720 | 140 | 13 | 44.3 | 300 | 185 | 225 | 265 | 340 | |||||||