Leave Your Message

-

Phone

-

E-mail

Ultrafine Iron Oxide Grinding has gained attention in various industries due to its unique properties and applications. This process involves reducing iron oxide particles to an ultrafine scale. Achieving superior performance in this grinding is essential for maximizing efficiency and product quality.

However, mastering ultrafine grinding techniques can be challenging. Factors like particle size, surface area, and the grinding medium play crucial roles. The choice of equipment is another critical consideration. While there are many methods available, their effectiveness can vary widely.

Experimentation is often needed to find the right balance. It is important to recognize that no single approach works for every situation. There is always room for improvement. Continuous refinement can lead to better outcomes in ultrafine iron oxide grinding. Observing and adapting to results is key for future success.

Grinding ultrafine iron oxide requires careful consideration of technique. Understanding the various methods available can significantly impact the efficiency of the grinding process. One popular method involves using ball mills. These machines rely on hard metal balls to crush the iron oxide into finer particles. However, achieving uniformity can be challenging. Not all materials respond well to this approach.

Jet milling is another technique that's worth exploring. It utilizes high-velocity air streams to create friction among the particles. This method is effective but can be wasteful. Some particles may over-grind, leading to unwanted size distributions. Optimizing the air pressure is critical. However, it often requires multiple trials to get it just right.

Lastly, the choice of grinding aids can directly affect performance. Additives can improve flow and reduce clumping. Yet, selecting the correct type is not always straightforward. Each additive can influence the final product in unexpected ways. Experimentation and reflection on results are essential. Small alterations in technique can lead to significant improvements in quality and efficiency.

Ultrafine iron oxide has unique properties that make it invaluable in various industries. This material boasts high surface area and excellent magnetic properties. According to recent studies, ultrafine iron oxide’s specific surface area can reach up to 100 m²/g. Such characteristics enhance its application in catalysis and magnetic storage systems.

The grinding process significantly affects the quality of ultrafine iron oxide. Proper techniques can yield a particle size below 100 nanometers, which is optimal for many applications. However, achieving this fine level remains challenging. Contamination during grinding can alter the properties, leading to subpar performance. Research indicates that maintaining low temperatures during the process can help preserve the material's integrity.

Another key aspect is the stability of ultrafine iron oxide in dispersive mediums. Factors like pH and ionic strength greatly influence its behavior. Inappropriate conditions can cause aggregation, counteracting its superior characteristics. Continuous monitoring and adjustment may be necessary to optimize its potential use in coatings and paints, among other applications.

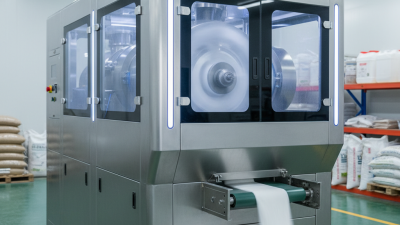

When it comes to grinding ultrafine iron oxide, selecting the right equipment is crucial. Various machines perform differently based on their design and technology. Ball mills are widely used. They can be effective in providing fine particles. However, they may not be the most efficient option for all situations.

Jet mills are another choice. They employ high-velocity air to grind materials, resulting in finer particles. Yet, scaling up this process can be challenging. It requires careful consideration of energy consumption and particle size distribution. Furthermore, some operators encounter difficulties in maintaining consistent quality.

The complexity in the grinding process often leads to trial and error. Finding the optimal speed and pressure requires experimentation. Not all techniques yield the same results, making it essential to monitor outcomes closely. If results don’t meet expectations, adjustments must be made. This iterative approach can be frustrating, but it's necessary for achieving superior performance. Aim for flexibility in your grinding strategy to navigate these challenges effectively.

In the world of ultrafine iron oxide grinding, various factors significantly impact grinding efficiency. One crucial element is the size of the grinding media. According to recent industry studies, smaller media can lead to more effective particle size reduction. The ideal diameter range for media is often between 0.5 mm and 5 mm, depending on the specific grinding equipment used. This finding reinforces that choosing the right media is essential for optimizing performance.

Another considerable influence on grinding efficiency is the feed material's properties. The hardness and moisture content can dramatically alter the grinding results. Research indicates that softer materials generally yield better grinding outcomes. Additionally, controlling moisture can prevent agglomeration, enhancing the grinding process. It’s worth reflecting on how overlooked factors like feed uniformity can impact overall efficiency.

**Tips:** To improve grinding results, regularly check media size and condition. Experimenting with different moisture levels in feed material can also yield better outcomes. Adjusting operational parameters like feed rate and speed may enhance efficiency. These adjustments often require trial and error, so be patient and ready to adapt.

| Technique | Particle Size (nm) | Energy Consumption (kWh/kg) | Efficiency (%) | Cost (USD/kg) |

|---|---|---|---|---|

| Ball Milling | 20 | 5.0 | 85 | 10.00 |

| Jet Milling | 15 | 7.5 | 90 | 12.50 |

| Disc Milling | 25 | 6.0 | 82 | 11.00 |

| Cryogenic Grinding | 10 | 8.5 | 95 | 15.00 |

Achieving consistent ultrafine particle size in iron oxide grinding requires a thorough understanding of the process. Various studies indicate that particle size significantly affects the properties of the final product. For instance, maintaining a target size of around 50 nanometers enhances reactivity and performance. This information is supported by a report that states materials with a size under 100 nanometers show improved applications in various industries.

Controlling milling parameters is crucial. Speed, duration, and media size all play a role. Research shows that a balance in these factors leads to more uniform particles. However, too high a speed can cause overheating and agglomeration. This can lead to variations in size, which may compromise the end product's quality. Rigorous monitoring is necessary here to mitigate potential issues.

Additionally, using wet grinding methods can help attain smaller sizes effectively. Data suggests that hydration during grinding reduces friction and energy consumption. Still, practitioners often overlook the importance of optimizing slurry concentration. Inconsistent mixtures can lead to unpredictable outcomes. Regular reviews of these practices can help refine processes and enhance consistency, ultimately driving superior performance in ultrafine iron oxide grinding.