Leave Your Message

-

Phone

-

E-mail

In the realm of advanced materials, "Ultrafine Iron Oxide Grinding" has emerged as a critical process for enhancing the performance characteristics of various applications. As industries strive for higher efficiency and superior quality, the need for finely milled iron oxide particles becomes increasingly essential. Dr. Emily Carter, a renowned expert in material science, emphasizes this need, stating, "The precision achieved through ultrafine grinding not only optimizes product performance but also opens new avenues for innovation across multiple sectors."

The process of ultrafine grinding transforms traditional iron oxide into a versatile material with remarkable properties such as increased surface area and improved chemical reactivity. These enhancements are pivotal for applications ranging from pigments in coatings to catalysts in chemical processes. The ability to achieve a uniform particle size ensures consistency and reliability in performance, making ultrafine iron oxide indispensable in high-performance applications.

In this context, understanding the intricacies of ultrafine iron oxide grinding is essential. As industries continue to evolve and demand higher standards, the role of this sophisticated grinding technique becomes increasingly pronounced. This article delves into the significance of ultrafine grinding, exploring its technological advancements, applications, and the future it holds in the material science landscape.

Ultrafine iron oxide plays a pivotal role in advanced manufacturing sectors, particularly due to its unique properties that enhance the performance of various materials. The ultrafine particle size allows for a larger surface area, which significantly improves reactivity and interactivity with other compounds. This characteristic is crucial in applications such as coatings, where the enhanced dispersion of ultrafine iron oxide can lead to superior adhesion and durability.

Furthermore, the ability of ultrafine iron oxide to impart magnetic and electrical properties makes it invaluable in electronics and energy storage devices.

In sectors like aerospace, automotive, and pigments, ultrafine iron oxide contributes to lightweight, high-strength materials that are essential for optimizing performance. The precision grinding of iron oxide to achieve ultrafine sizes ensures that manufacturers can fine-tune material properties to meet specific applications, such as improving corrosion resistance and thermal stability. As industries continue to push the boundaries of innovation, the significance of ultrafine iron oxide will only grow, fueling advancements in sustainable and high-performance materials that meet the demands of the modern world.

In high-performance applications, the particle size distribution (PSD) of ultrafine iron oxide plays a crucial role in determining the material's effectiveness and functionality. Research has indicated that the optimal PSD can significantly enhance the properties of materials, particularly in sectors such as coatings, electronics, and catalysts. A tighter PSD, often achieved through advanced grinding techniques, allows for improved dispersion and better performance in end-use applications. For instance, studies show that a uniform particle size can lead to increased surface area, which directly correlates with enhanced reactivity and strength in composite materials.

Moreover, specific data reports highlight that ultrafine iron oxide with a PSD focused around 50-100 nanometers can improve magnetic properties, which is essential in electronic components, where efficiency and miniaturization are paramount. The distribution of these particles is not only critical for performance but also for processing stability; a well-distributed size range minimization reduces sedimentation and agglomeration challenges during application. Notably, the Journal of Nanomaterials observed that smaller and uniformly distributed particles could enhance mechanical properties by up to 30% compared to larger particles, underscoring the importance of meticulous control over grinding processes in achieving desired material characteristics for high-performance applications.

| Particle Size (µm) | Specific Surface Area (m²/g) | Density (g/cm³) | Applications | Performance Characteristics |

|---|---|---|---|---|

| 0.1 | 70 | 5.2 | Pigments, Coatings | High opacity, excellent dispersion |

| 0.2 | 55 | 5.3 | Electromagnetic Shielding | Enhanced magnetic properties |

| 0.5 | 40 | 5.1 | Composite Materials | Improved strength and durability |

| 1.0 | 30 | 4.9 | Ceramics, Glass | Improved thermal resistance |

| 2.0 | 20 | 4.5 | Construction Admixtures | Enhanced workability |

Ultrafine iron oxide is increasingly recognized for its transformative role in the fields of coatings and composites. In coatings, the incorporation of ultrafine iron oxide particles enhances not only the aesthetic appeal but also the durability and corrosion resistance of the final product. These fine particles contribute to a uniform color and sheen while providing excellent opacity and UV protection, making them highly desirable in automotive and architectural applications. Their ability to improve adhesion properties further allows for a longer-lasting finish, which is essential for surfaces exposed to harsh environmental conditions.

In composites, ultrafine iron oxide serves as a critical filler that improves mechanical properties and thermal stability. By enhancing tensile strength and impact resistance, these materials are able to perform better under stress, making them suitable for advanced engineering applications. The nanoscale size of the iron oxide particles ensures a high surface area to volume ratio, facilitating better dispersion within the composite matrix. This results in improved overall performance and resilience, effectively meeting the stringent demands of industries such as aerospace, electronics, and construction. The integration of ultrafine iron oxide not only leads to enhanced functionality but also promotes innovations in material design.

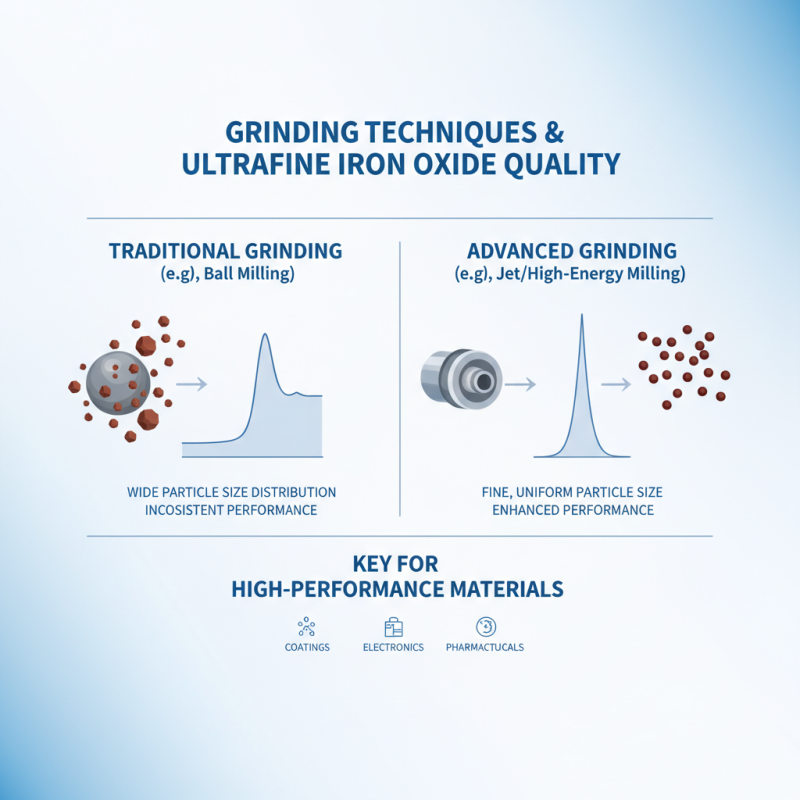

The quality of ultrafine iron oxide is significantly influenced by the grinding techniques employed during production. Traditional grinding methods, such as ball milling, can produce a wide distribution of particle sizes, leading to inconsistencies in performance. In contrast, advanced grinding techniques, like jet milling or high-energy milling, allow for more precise control over particle size and surface characteristics. These methods can achieve a finer and more uniform particle distribution, which is essential for applications requiring high-performance materials, such as in coatings, electronics, and pharmaceuticals.

Moreover, the choice of grinding technique directly affects the physical and chemical properties of the iron oxide. For instance, jet milling utilizes high-velocity air streams that not only reduce particle size but also preserve the integrity of the material, minimizing contamination and alteration of its surface chemistry. Conversely, conventional milling techniques may introduce impurities, affecting the iron oxide’s performance in end-use applications. Thus, optimizing the grinding process is crucial to enhancing the overall quality and functionality of ultrafine iron oxide, ensuring that it meets the rigorous demands of high-performance industries.

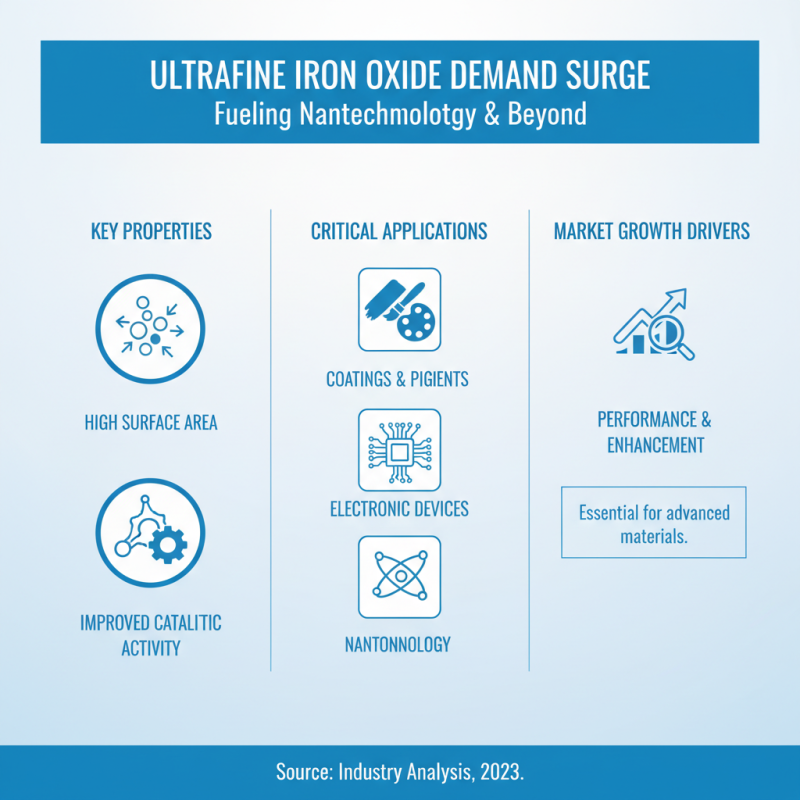

The demand for ultrafine iron oxide has surged recently due to its critical applications in various sectors, particularly in nanotechnology. As industries increasingly seek materials that enhance performance and efficiency, ultrafine iron oxide offers unique properties such as high surface area and improved catalytic activity. These characteristics make it an invaluable component in coatings, pigments, and electronic devices, fueling the growth of the nanotechnology market.

Market trends indicate a growing inclination towards the incorporation of ultrafine iron oxide in advanced materials. The capabilities of ultrafine iron oxide to improve thermal stability and corrosion resistance are driving its adoption in innovative applications, including energy storage systems and nanocomposites. As research progresses and technology evolves, the versatility of ultrafine iron oxide continues to expand, meeting the needs of industries aiming for superior performance and sustainability in their products. This trajectory suggests that the market demand for ultrafine iron oxide will remain robust, as it plays a pivotal role in the future of nanotechnology and high-performance applications.