Leave Your Message

-

Phone

-

E-mail

Ultrafine Grinding Crusher has become essential in various industries today. This equipment efficiently reduces particle sizes, enhancing product quality and functionality. Its uses span across food processing, pharmaceuticals, and material science.

Many benefits accompany the Ultrafine Grinding Crusher. For instance, it improves solubility and bioavailability in drug formulations. In food applications, it can create smoother textures without compromising flavor. Yet, there can be challenges. Finding the right settings may require experimentation.

The potential for this technology is great. However, not all users fully understand its capabilities. A deeper exploration into its operation and applications may reveal untapped advantages. This could lead to innovation and efficiency in production processes.

Ultrafine grinding is a mechanical process that produces particles smaller than 10 micrometers. This method is crucial in various industries, including pharmaceuticals and food processing. Achieving such fine particle sizes enhances solubility and bioavailability. The process typically involves grinding materials using various mills, including jet and ball mills.

Data suggests that ultrafine grinding can increase the value of raw materials. According to a recent study, fine powders can boost extraction yields by up to 30%. This increase is particularly valuable for industries extracting active compounds. When particle sizes are reduced, the surface area expands, improving the reaction rates during extraction.

Tip: Always monitor the temperature while grinding. Excess heat can alter material properties and quality. Another consideration is the feed rate. A slower feed rate might improve product uniformity. Experimenting with these factors can lead to better results.

However, achieving the perfect particle size can be challenging. Too fine a grind can lead to material agglomeration. This can complicate subsequent processing steps. It's important to balance the fineness of the grind with the intended application. Each product may have unique characteristics that require tailored approaches.

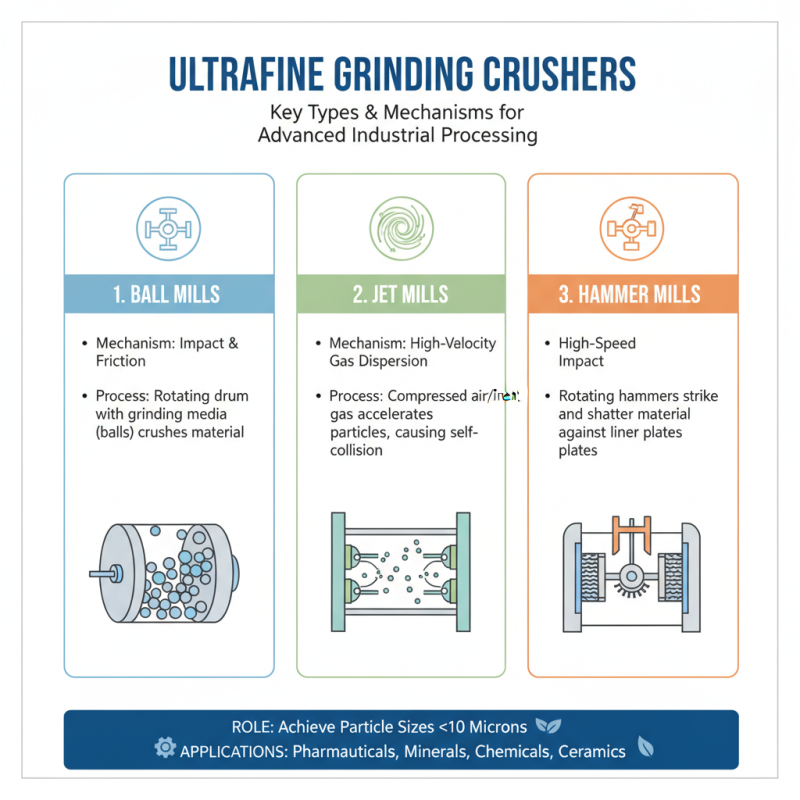

Ultrafine grinding crushers play a pivotal role in various industries. The mechanisms of these crushers can be broadly categorized into several types. Ball mills, jet mills, and hammer mills are among the most commonly used. Each type operates on distinct principles to achieve ultrafine particle sizes. For instance, jet mills utilize high-velocity gas to disperse particles, while ball mills rely on impact and friction.

According to industry reports, ultrafine grinding can increase specific surface area by up to 40%. This enhancement leads to improved reactivity in chemical processes. In pharmaceuticals, for example, finer particles can enhance drug solubility and bioavailability. The choice of crusher significantly affects the final product's characteristics, including uniformity and granule size distribution.

Tips: Consider your material's properties before selecting a crusher. Harder materials may require different mechanisms compared to softer substances. Understand the potential trade-offs in energy consumption versus output quality. Furthermore, it's essential to reflect on the environmental impact and waste generated during ultrafine grinding. Balancing efficiency with sustainability is an ongoing challenge in this field.

Ultrafine grinding is becoming increasingly essential in various industries. One of the most notable benefits is achieving superior particle size reduction. For instance, in the pharmaceutical sector, particle size significantly influences drug solubility and bioavailability. According to a study from the American Pharmaceutical Review, optimal particle sizes can enhance drug effectiveness by up to 30%.

In the food industry, ultrafine grinding improves texture and flavor release. This technology allows manufacturers to create finer powders, which are crucial for products like spices and flavorings. The market for such ground materials is projected to grow at a rate of 6.5% per year until 2029, indicating a strong trend towards more refined ingredients.

However, ultrafine grinding is not without its challenges. The process can be energy-intensive, requiring careful management. Additionally, wear and tear on equipment can lead to increased maintenance costs. Companies must weigh these factors against the benefits to ensure sustainability. While the advantages are compelling, the implementation process needs ongoing review and adjustment to maximize efficiency.

Ultrafine grinding plays a pivotal role in various industries, particularly in pharmaceuticals, food processing, and materials science. The demand for fine particle sizes has surged, driven by the need for better solubility and improved absorption rates. Reports indicate that the global ultrafine grinding market is expected to reach $10 billion by 2025, highlighting its significance.

In pharmaceuticals, ultrafine grinding enhances the bioavailability of active ingredients. For instance, the average particle size reduction can lead to a 40% increase in the dissolution rate of certain drugs. This is crucial for developing effective medications. In food processing, obtaining finer particles improves flavors and textures. A study found that ultrafine grinding can boost the extraction of antioxidants by up to 25%, which benefits health products.

Despite its advantages, ultrafine grinding presents challenges. The process can generate excessive heat, potentially degrading sensitive materials. Moreover, achieving the desired size distribution requires careful calibration. Each application may demand different setups, making consistency a common hurdle. Understanding these nuances is vital for industries seeking to leverage ultrafine grinding effectively.

When considering an ultrafine grinding crusher, several factors come into play. The material type is crucial. Different materials require varying techniques for effective grinding. Hard materials may need robust machinery, while softer ones could work with simpler designs. Assess the desired particle size. Some processes need extremely fine particles, impacting the choice of equipment.

Energy efficiency is another vital aspect. An efficient grinder reduces operational costs over time. Operating at the right speed can influence the outcome. Slower speeds may yield finer results but take longer. Conversely, high speeds may cause overheating and inconsistency.

Dust control is essential in these operations. Excessive dust can affect product quality and worker safety. Choosing equipment with proper dust collection systems is important. The initial setup cost must also be weighed against long-term benefits. Sometimes, a higher initial investment leads to better returns later on. It's crucial to evaluate all these elements to make an informed decision.