Leave Your Message

-

Phone

-

E-mail

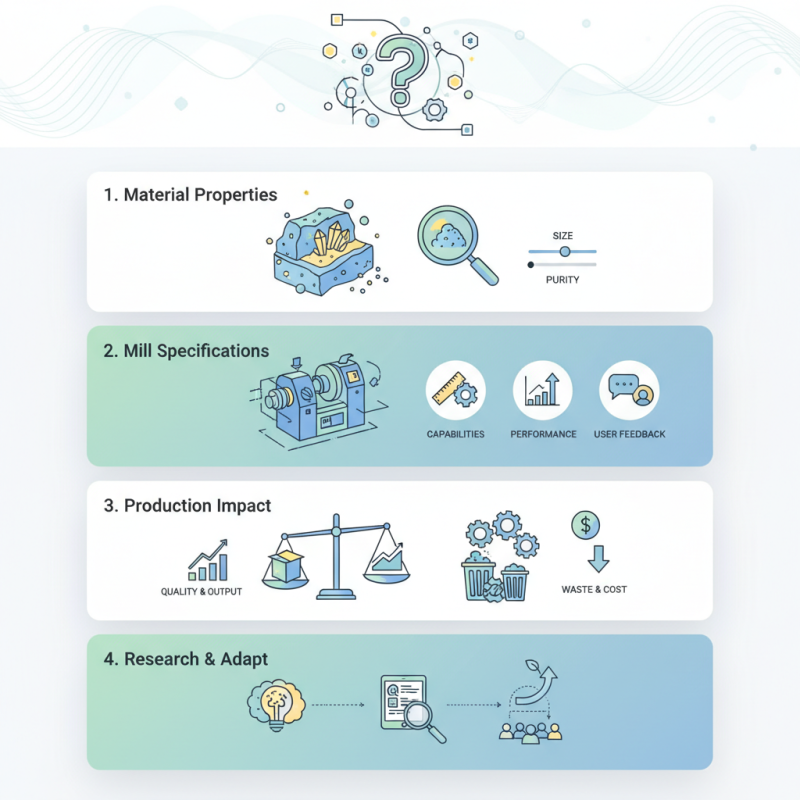

Choosing the right Ultrafine Quartz Powder Mill can be challenging. It requires careful consideration of various factors. This choice significantly affects your production quality.

When selecting a mill, focus on the material's properties. The right size and purity are crucial. Not every mill suits every project. Some may underperform or lead to waste. Poor decisions can impact your budget and output.

Research various options. Understand each mill's specifications and capabilities. Gather feedback from other users. Sometimes, the real performance differs from the advertised features. Always be open to learning from your choices to ensure the best results.

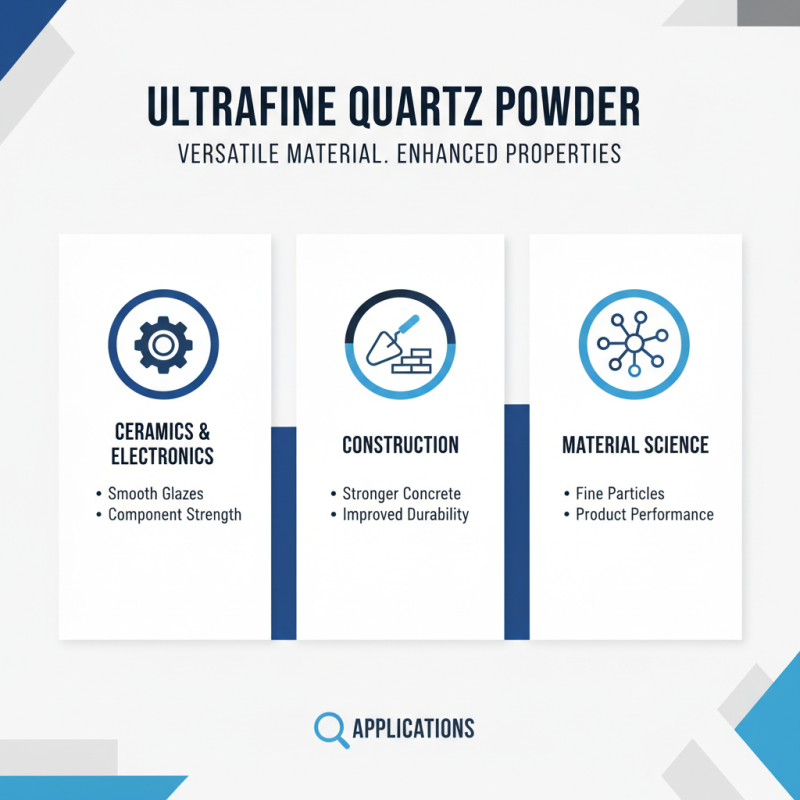

Ultrafine quartz powder is a versatile material with various applications. It is used in industries like ceramics, electronics, and construction. The fine particles enhance the properties of many products. For example, they improve the strength and durability of concrete. Additionally, ultrafine quartz contributes to the smoothness of ceramic glazes.

Choosing the right mill for producing ultrafine quartz powder can be challenging. The correct mill can enhance efficiency and product quality. Factors like particle size and shape should be considered. Some mills may not achieve the desired consistency. Others may produce too much waste. It's crucial to evaluate the available options carefully.

When exploring mills, users often find insufficient information. Not all machines are equal in performance. Some may require frequent maintenance, leading to downtime. This could impact production schedules. Observing and reflecting on the performance over time is essential for improvement. Finding the best mill involves trial and error, but the right choice can lead to significant advantages.

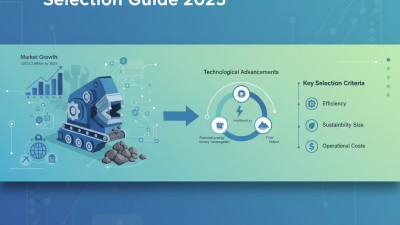

Choosing the right ultrafine quartz powder mill requires careful consideration. The market is vast, and various factors influence efficiency and output quality. According to recent industry reports, the global demand for high-purity quartz is expected to grow at a CAGR of 7.6% from 2021 to 2026. Selecting a mill that aligns with this trend is crucial for businesses.

One key factor to consider is the mill's capacity. Assess how much quartz powder you need to produce regularly. Mismatches here can affect your production line. Another important consideration is the energy efficiency of the mill. Reports suggest that energy costs account for up to 40% of production expenses. Choosing a mill that minimizes energy consumption can significantly reduce overall costs.

Tip: Look for mills with advanced technology that offer better grind sizes and lower contamination rates. Furthermore, don’t overlook maintenance ease. A complex mill might require more downtime, affecting productivity. Evaluate feedback and reviews from other users. Sometimes, real-world experiences reveal flaws that data cannot show. Balancing these factors can help you choose wisely.

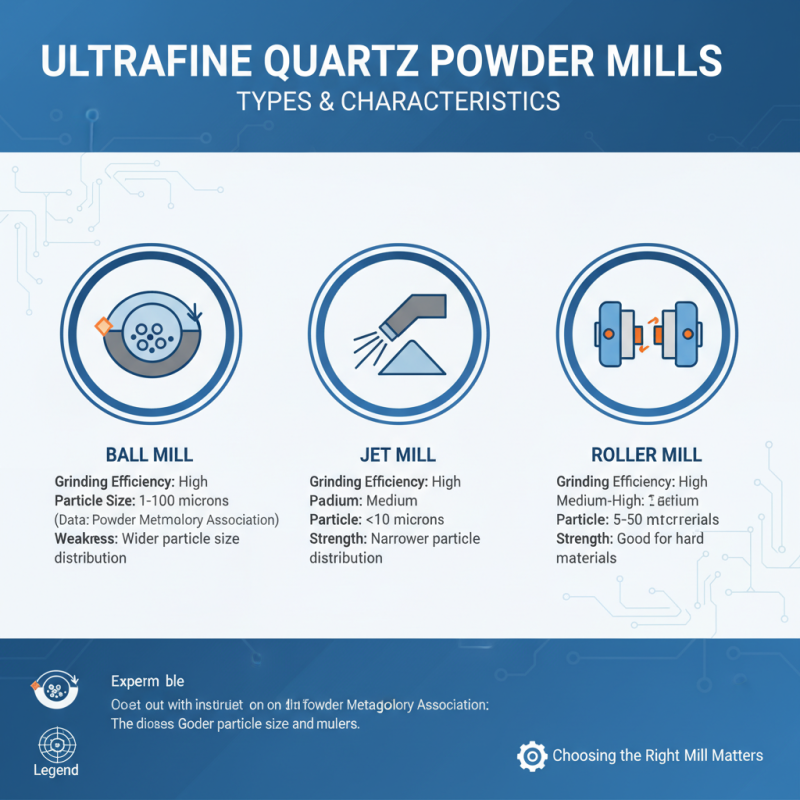

When choosing an ultrafine quartz powder mill, understanding the different types available is crucial. There are several mill designs, including ball mills, jet mills, and roller mills. Each type has its own strengths and weaknesses. For instance, ball mills are known for their efficiency in grinding, but they can produce wider particle size distributions. A data report from the Powder Metallurgy Association highlights that ball mills generally achieve particle sizes in the range of 1 to 100 microns.

Jet mills, on the other hand, can create much finer particles, often below 10 microns. However, they require substantial energy input to operate efficiently. A study by the International Journal of Mineral Processing indicates that while jet mills offer precision, they can also lead to larger production costs. Understanding these trade-offs is essential.

Roller mills are less common but can be effective for specific applications. They tend to produce less wear and tear on materials. However, some users report that achieving ultrafine particle sizes can be challenging. It's important to reflect on your specific needs before making a decision. Evaluate factors like energy consumption, maintenance, and cost-effectiveness. The right choice often depends on balancing these factors with the required product specifications.

When assessing ultrafine quartz powder mills, efficiency and output are paramount. Industry reports indicate that mills can vary significantly in performance. For instance, a mill with optimal parameters may achieve up to 95% material utilization. This means less waste and better cost-effectiveness. However, not all models reach this benchmark. A thorough analysis of the mill’s specifications is crucial.

Output considerations also play a key role. Reports suggest that mills operating between 1,000 to 2,500 RPM tend to deliver the highest quality powder. Additionally, the particle size distribution matters. A consistent size can enhance performance in applications. Yet, achieving this may require multiple adjustments. Operators must pay attention to maintenance schedules. Ignoring these can lead to reduced efficiency over time.

The choice of grinding medium can impact results as well. Some materials produce finer powders while being energy-intensive. Balancing energy consumption with desired output can be challenging. Decisions made in this phase influence production capabilities. Reflection on these aspects might reveal areas for improvement. Identifying weaknesses early in the selection process is vital for success.

When investing in an ultrafine quartz powder mill, maintenance and support should not be overlooked. Regular maintenance extends the life of your mill. This includes checking for wear and tear on essential components. Are the grinding plates properly aligned? Misalignment can lead to inefficiency and even damage.

Monitoring the performance of the mill is crucial. Listen for unusual noises during operation. These may indicate a problem. Vibration levels should also be tracked. High vibration can signal issues that may compromise performance. Don’t ignore warning signs; they often lead to costly repairs later.

Utilizing proper cleaning techniques is essential. Residue build-up can affect the quality of the quartz powder. Schedule regular cleaning to maintain optimal performance. Document your maintenance tasks. A clear log helps in identifying patterns and potential issues. Overall, adequate care will ensure the longevity of your mill, and provide a better return on investment.