Leave Your Message

-

Phone

-

E-mail

The industrial sector is constantly evolving, and one of the critical components driving this progress is the industrial crusher. As the demand for efficient and reliable materials processing increases, understanding the different types of crushers available is essential for businesses looking to thrive in a competitive market. Renowned industrial expert Dr. Emily Carter once stated, "The right industrial crusher not only enhances production efficiency but also optimizes resource utilization."

In 2023, various innovations and advancements in industrial crushers are making waves in the manufacturing and processing industries. From jaw crushers to impact crushers, each type serves a unique purpose and comes with distinct advantages. Businesses must stay informed about these developments to choose the right equipment tailored to their specific needs and operational goals.

As we delve into the top 10 industrial crushers you need to know about, we will explore the features, benefits, and applications of each machine. This knowledge will empower industry professionals to make informed decisions and harness the true potential of their material handling processes. With the right insights and strategies, companies can significantly enhance their productivity and reduce operational costs in 2023 and beyond.

Industrial crushers play a pivotal role in various sectors, including construction, mining, and recycling, by efficiently breaking down materials into manageable sizes for subsequent processing. In 2023, the landscape of industrial crushers has evolved significantly, driven by advancements in technology and the growing emphasis on sustainability. These machines are now designed not just for raw power, but for efficiency, versatility, and environmental compliance. With new designs and innovations, manufacturers have focused on enhancing performance while reducing operational costs and energy consumption.

As industries seek to optimize their operations, the range of crushers available reflects a broader trend towards specialization. From jaw and cone crushers that are essential for hard rock applications to impact crushers tailored for softer materials, each type addresses specific needs. Additionally, the integration of smart technology in these machines allows for real-time monitoring and data analytics, enabling users to make informed decisions about maintenance and operation. This modernization not only improves productivity but also helps industries meet stringent environmental regulations by minimizing waste and emissions during the crushing process. In this dynamic arena, understanding the capabilities and applications of different industrial crushers is crucial for businesses aiming to enhance their operational efficiency and sustainability in 2023.

| Rank | Type | Capacity (tons/hour) | Power (kW) | Applications |

|---|---|---|---|---|

| 1 | Jaw Crusher | 150 | 110 | Mining, Construction |

| 2 | Cone Crusher | 200 | 132 | Aggregates, Quarrying |

| 3 | Impact Crusher | 100 | 75 | Recycling, Construction |

| 4 | Vertical Shaft Impact Crusher | 80 | 55 | Sand Production, Gravel |

| 5 | Roll Crusher | 160 | 90 | Mining, Chemical |

| 6 | Hammer Crusher | 120 | 75 | Coal, Biomass |

| 7 | Gyratory Crusher | 240 | 160 | Mining, Metallurgy |

| 8 | Mobile Crusher | 70 | 80 | Construction, Demolition |

| 9 | Stone Crusher | 140 | 100 | Railway, Highway |

| 10 | Concrete Crusher | 90 | 65 | Recycling, Waste Management |

When selecting an industrial crusher, several key features must be taken into consideration to ensure optimal performance and efficiency. One of the most important factors is the material type that the crusher is designed to process. According to a recent industry report by Mordor Intelligence, the global market for industrial crushers is expected to grow significantly, driven by the demand for different materials ranging from minerals to biomass. Understanding the hardness, abrasiveness, and moisture content of the input material will help in choosing the right crusher type, whether it be jaw, cone, or impact crushers.

Another critical aspect to evaluate is the crusher's capacity and energy consumption. An efficient crusher can significantly reduce operational costs, enabling companies to maximize productivity. The same report indicates that advancements in technology have led to the development of energy-efficient models that utilize up to 30% less energy compared to traditional crushers. Additionally, factors such as maintenance requirements, ease of operation, and safety features should not be overlooked, as they can greatly influence the overall operational workflow and downtime in production environments. Thus, assessing these key features will support the selection of a crusher that best meets the specific needs of your industry application.

Industrial crushers are vital components in various manufacturing and processing industries, serving a range of applications from raw material preparation to waste management. One popular application is in the mining sector, where crushers break down large ore deposits into manageable sizes for further processing. These machines enhance efficiency and productivity by ensuring that minerals are crushed to the appropriate granularity for extraction.

Another significant application is in the construction industry, where crushers help recycle concrete and asphalt from demolition sites. This recycling process not only reduces waste but also provides quality materials for new construction projects. In addition, crushers are utilized in the food processing industry, helping to grind and pulverize materials such as grains and spices, paving the way for improved food production processes. The versatility of industrial crushers ensures their continued relevance across various sectors in 2023 and beyond.

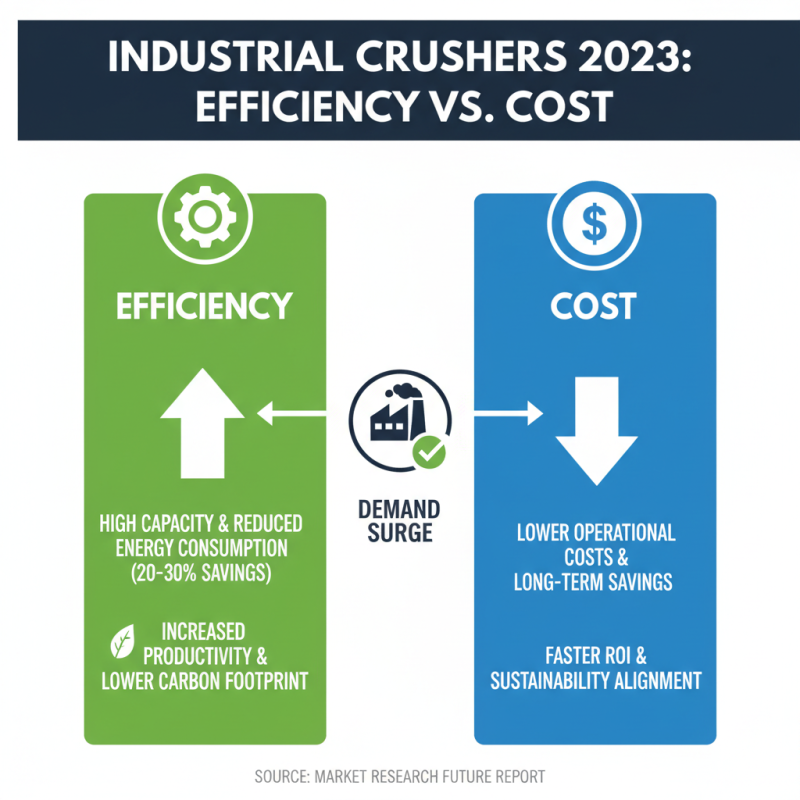

As industries advance in 2023, the demand for efficient and cost-effective industrial crushers has surged. This comparative analysis focuses on the two crucial aspects: efficiency and cost. According to a recent industry report by Market Research Future, the efficiency of crushers can significantly influence operational productivity. For instance, high-capacity crushers that reduce energy consumption by 20-30% are becoming increasingly popular, as they not only minimize operational costs but also lower carbon footprints, aligning with sustainability goals.

When evaluating costs, businesses must consider both the initial purchase price and the long-term operational expenses. A study from Global Industry Analysts revealed that advanced crushing systems, while more expensive upfront, often result in lower maintenance costs and fewer downtime incidents, which can lead to substantial savings over time. Thus, organizations are encouraged to take a holistic view of their investment, examining total cost of ownership rather than merely purchase prices.

**Tip:** Always conduct a total cost analysis to ensure that you’re not only looking at the purchase cost of a crusher but also considering operational, maintenance, and energy costs over its lifetime.

**Tip:** Stay updated with industry reports and analyses to benchmark your choices against the latest efficiency standards and technological advancements, which can guide you in choosing the right equipment for your needs.

As we move deeper into 2023, industrial crusher technology continues to evolve, driven by the need for efficiency, sustainability, and automation. One notable trend is the increasing integration of advanced sensors and AI technology into crushing equipment. These innovations not only enhance the performance and precision of crushers but also facilitate predictive maintenance by monitoring equipment health in real-time. Such developments help reduce downtime and maintenance costs, providing a significant advantage in competitive markets.

In addition to automation, the industry is shifting towards sustainable practices. There is a growing emphasis on designing crushers that minimize energy consumption and reduce waste. Advances in materials science are leading to the creation of more durable components that require less frequent replacement. This not only lowers operational costs but also aligns with global initiatives aimed at reducing the environmental impact of industrial processes.

Tips: When selecting an industrial crusher for your operation, consider the long-term implications of energy efficiency and maintenance. Look for models that offer smart technology features, as these can significantly enhance your operation's productivity while supporting sustainability goals. Additionally, keeping abreast of technological advancements will help your business stay competitive in an ever-evolving industry landscape. Emphasizing innovation and sustainability in your equipment choices can lead to significant long-term benefits.