Leave Your Message

-

Phone

-

E-mail

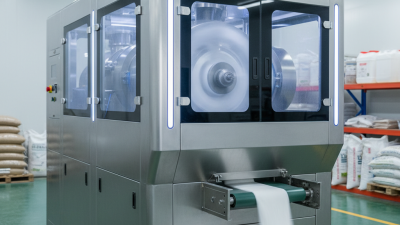

In the realm of industrial processing, the significance of Continuous Ball Mill Equipment cannot be overstated. This machinery plays a pivotal role in grinding various materials efficiently. Many industries rely on these systems for their operations. With advancements in technology, the latest models offer improved efficiency and performance. Choosing the right equipment is vital.

However, not all Continuous Ball Mill Equipment is created equal. Equipment selection can be difficult. Businesses must consider several factors. The capacity, energy consumption, and material compatibility all influence productivity. Some models excel in certain applications but fall short in others.

As companies aim for optimal processing, they face challenges. Maintenance often becomes a concern. Regular checks and updates are necessary for longevity. Additionally, operators must be trained to maximize efficiency. This presents a need for ongoing assessment of processes. Balancing performance with practicality remains an ongoing journey.

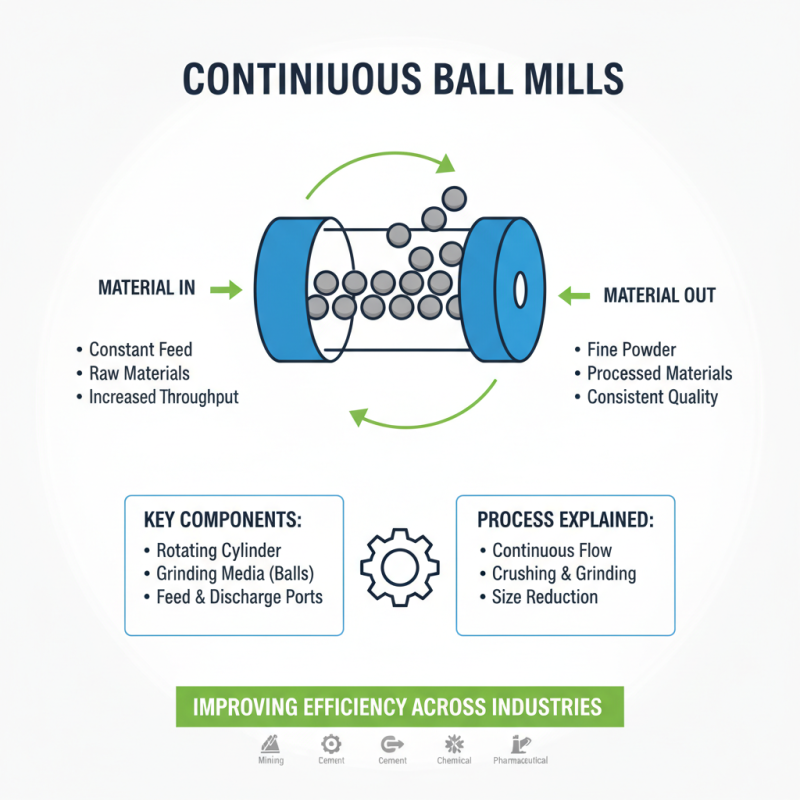

Continuous ball mills play a crucial role in material processing. They allow for a constant flow of materials, improving efficiency in various industries. These mills consist of a rotating cylinder filled with grinding balls. As the cylinder rotates, the balls crush and grind the material inside.

In operation, continuous ball mills require careful attention. The size and type of material impact the grinding outcome. If the input material is too large, inefficiency may occur. Monitoring the speed and feed rate is essential to optimize performance. An improper balance can lead to wasted energy and longer processing times.

While continuous ball mills simplify processes, they are not without challenges. Regular maintenance is necessary to avoid wear and tear. Operators must ensure the equipment runs smoothly. Understanding the functionality helps in troubleshooting potential issues. Observing the performance closely allows for adjustments, leading to better efficiency.

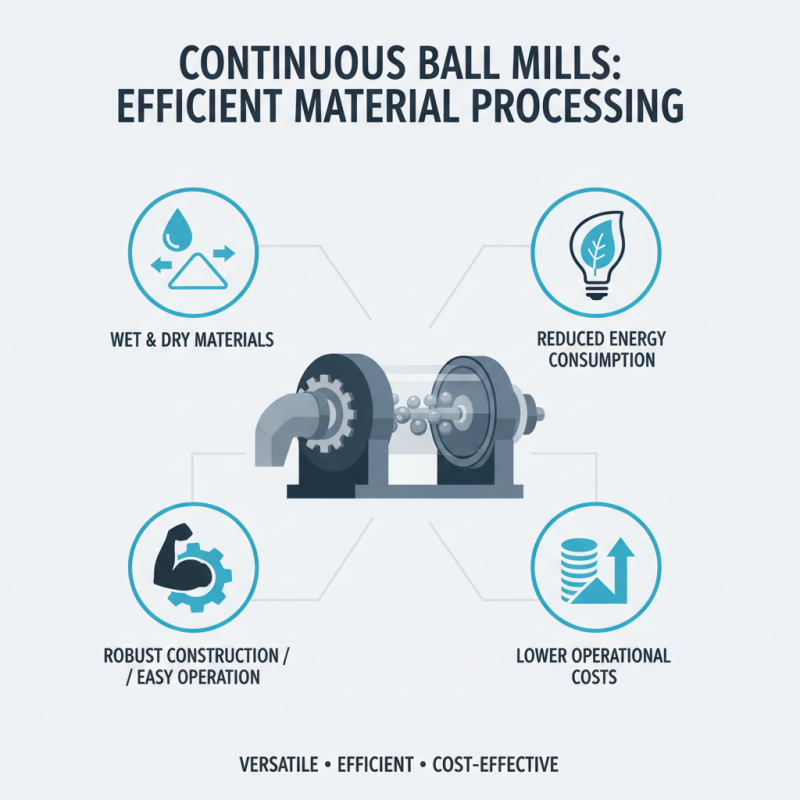

Continuous ball mills are essential tools for efficient material processing in various industries. An ideal continuous ball mill combines robust construction with ease of operation. One key feature is the ability to handle wet and dry materials seamlessly. This versatility allows manufacturers to meet diverse production needs. Additionally, a well-designed ball mill reduces energy consumption, which can significantly cut operational costs.

Moreover, ease of maintenance is paramount. Operators should look for mills that offer straightforward access to components. This feature allows for quick repairs and minimizes downtime. Another noteworthy characteristic is the adjustable speed control. This function enables better control over the grinding process, which can enhance product quality.

However, even the best equipment may have limitations. Sometimes, the grinding efficiency might not meet expectations. Factors like material properties can influence this. Regular monitoring of performance is necessary. Observing how the equipment interacts with different materials can provide valuable insights. Balancing these reflections with machine capabilities can lead to improved processing outcomes.

Continuous ball mills have become essential in material processing. These machines provide a constant flow of materials. This efficiency is crucial for industries that demand high production rates. With continuous operation, materials can be processed consistently, reducing downtime.

One notable advantage is the uniformity of particle size. Continuous ball mills ensure that materials are ground to a consistent fineness. This is beneficial, especially in sectors like mining and construction. However, operators must monitor the process closely. Variations in feed materials can lead to unexpected results. Sometimes, this leads to the need for adjustments, which can be unpredictable.

Another benefit is the enhanced energy efficiency. Continuous systems often consume less energy than batch processes. However, initial setup costs can be high. This deters some companies from switching to continuous mills. Operational challenges may arise, requiring skilled personnel for effective management. Continuous ball mills indeed offer many advantages, but they come with their own set of challenges. Balancing these factors is essential for optimal performance.

When selecting continuous ball mills, it's crucial to compare different brands and models. According to industry reports, the efficiency of material processing can vary significantly. Some models achieve up to 90% effectiveness in particle size reduction, while others might only reach 70%. The gap in performance highlights the importance of detailed analysis before making a choice.

Leading brands demonstrate unique features. Some mills offer adjustable speed settings, allowing customization for diverse materials. Others focus on durability and maintenance ease, which leads to additional cost savings. Reports also indicate that models with closed-circuit systems can improve the overall grinding process efficiency by recycling material.

However, alongside advancements, challenges exist. High energy consumption remains a concern for many users. Some mills generate excessive heat, impacting material properties. Understanding these issues is vital for optimizing performance and ensuring that production goals are met. A careful review of specifications and performance metrics is essential for every operator.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Capacity (tons/hour) | 5 | 10 | 7 |

| Power Consumption (kW) | 20 | 35 | 25 |

| Material Types | Ceramics, Minerals | Metals, Alloys | Cement, Coal |

| Ball Diameter (mm) | 25 | 30 | 28 |

| Operational Efficiency (%) | 85 | 90 | 88 |

Maintaining continuous ball mills is crucial for efficient operations. Regular inspections should be part of your routine. Check wear and tear on components like liners and grinding media. This can prevent unexpected breakdowns. A well-maintained mill operates smoother and more efficiently.

Lubrication practices are often overlooked. Proper lubrication extends equipment lifespan. Use the right type and amount of lubricant. Over-lubrication can lead to issues just as much as under-lubrication. Keep track of lubrication schedules to avoid inconsistencies.

Operators should be trained thoroughly. Misunderstandings about equipment can lead to inefficient processing. Encourage regular feedback from staff. They know the equipment best. Adjust maintenance schedules based on their input. Neglecting these details can result in downtime, costing more than expected.