Leave Your Message

-

Phone

-

E-mail

In the world of industrial milling, the Semi-Continuous Ball Mill stands out as an innovative solution. This mill combines the advantages of continuous and batch milling processes, making it efficient for various applications. Dr. John Smith, a leading expert in milling technology, emphasizes its significance: "The Semi-Continuous Ball Mill enhances productivity while maintaining product quality."

The design of the Semi-Continuous Ball Mill allows operators to achieve remarkable results. With its unique configuration, materials are fed into the system continuously, yet the milling process resembles traditional methods. This blend of techniques is particularly beneficial for industries such as mining and chemicals. However, the operation requires careful management. Operators must ensure consistent feed rates and monitor the milling environment closely.

There are challenges in mastering the Semi-Continuous Ball Mill. Adjustments in settings may lead to unexpected outcomes. It's essential to reflect on these experiences to improve future processes. Despite its advantages, the technology is not foolproof. Continuous learning is vital to refine operations and achieve optimal results.

A semi-continuous ball mill is a type of milling machine. It combines features of both continuous and batch mills. This design allows for efficient processing of materials in various industries.

The operation of a semi-continuous ball mill involves feeding the material gradually. The grinding media, often balls, crush and break down particles as they move through the mill. This process enables a consistent product while reducing downtime. However, the balance between input and output can sometimes be challenging. Material may not always transition smoothly.

Users of semi-continuous mills must monitor several factors. For instance, the flow rate can affect the quality of the product. If too fast, it may lead to incomplete grinding. Additionally, some adjustments might not be intuitive. These factors require careful attention and regular adjustments for optimal performance.

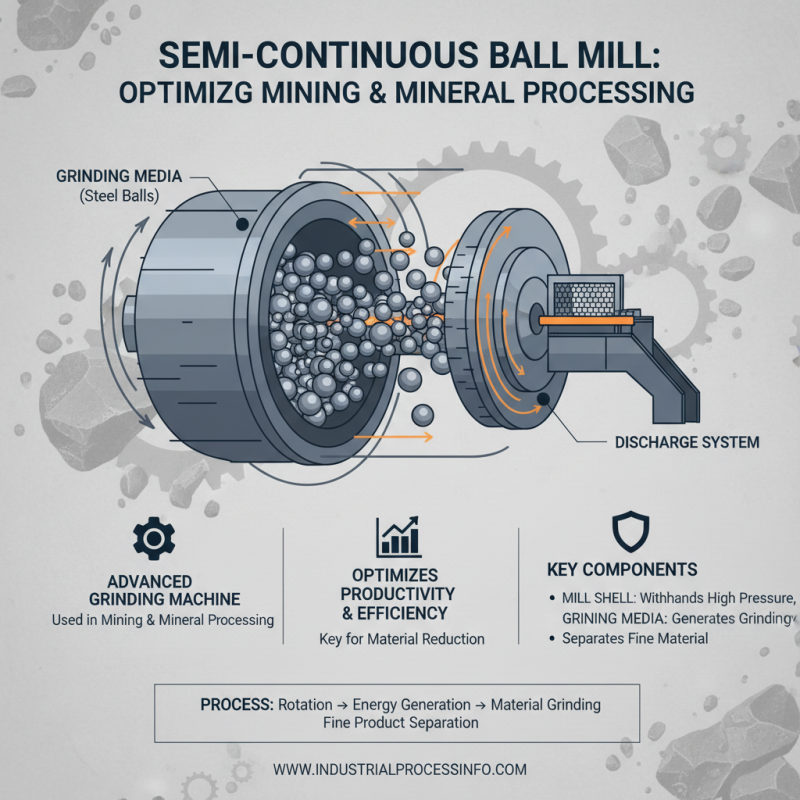

A semi-continuous ball mill is an advanced grinding machine used primarily in mining and mineral processing. It plays a vital role in optimizing productivity and efficiency. Key components of this machinery include the mill shell, grinding media, and discharge system. The mill shell is designed to withstand high pressure during grinding. It facilitates the rotation of the grinding media. This rotation generates the necessary energy for the grinding process.

Grinding media varies from steel balls to ceramic materials. The choice affects the grinding efficiency and product quality. According to industry reports, using the right type of media can increase efficiency by up to 30%. The discharge system is crucial, as it determines how efficiently the finished product exits the mill. An inefficient discharge can lead to clogging and decreased output.

Tips: Regular maintenance is essential for mill longevity. Check for wear on grinding media and the shell. Implementing a monitoring system can help identify maintenance needs early. Additionally, consider the material being processed. Different materials may require adjustments in media type and size. A mismatch can reduce overall effectiveness and increase energy costs. Addressing these aspects leads to sustainable operation.

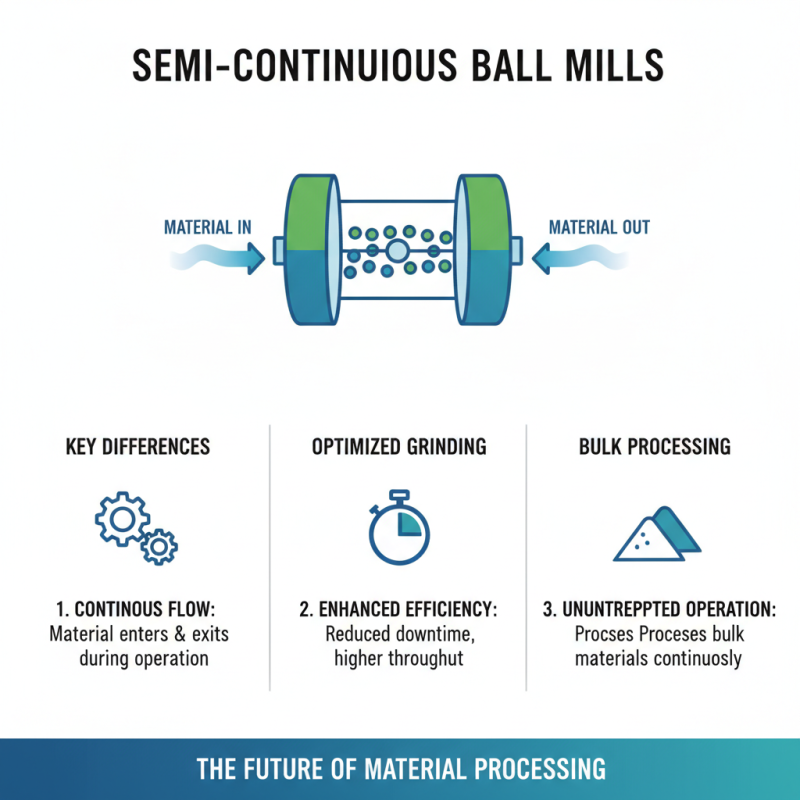

Semi-continuous ball mills play a vital role in material processing. They differ from traditional ball mills by allowing materials to flow in and out during operation. This design optimizes the grinding process, enhancing efficiency while reducing downtime. With semi-continuous operation, the milling mechanism can process bulk materials without frequent interruptions.

The operation of semi-continuous ball mills involves a unique combination of batch and continuous processing. As raw materials are added, the mill grinds them while simultaneously expelling finished products. This design requires careful monitoring of the feed and discharge rates, which can be challenging. Inconsistent flow can lead to uneven product quality or prolonged processing times.

Operators often face the dilemma of balancing input and output. If the input rate is too high, it overwhelms the system. If it's too low, efficiency drops significantly. It’s a complex dance of adjusting parameters to maximize the effectiveness of the mill. Mistakes can happen. Learning from these experiences helps in refining operational strategies over time.

Semi-continuous ball mills are essential in various industrial applications. They efficiently grind materials in processes such as cement production, mineral processing, and chemical manufacturing. A recent market analysis indicates that the global ball mill market is projected to reach $6 billion by 2025, driven primarily by the demand in these sectors.

In the cement industry, semi-continuous ball mills play a crucial role. They enhance the quality of the final product by ensuring uniform particle size. Reports show that about 30% of production costs are linked to milling processes. Companies often grapple with optimizing these costs while maintaining efficiency. Energy consumption in these mills can be high, demanding constant adjustment and monitoring to prevent wastage.

Another significant application is in mineral processing. Semi-continuous mills can process various ores, improving yield. However, the complexity of operation can lead to challenges. For example, varying hardness of ores may disrupt grinding efficiency. The need for frequent calibration becomes apparent. A balance between output and operational efficiency is vital for maximizing potential.

Semi-continuous ball mills are a unique type of milling equipment. They combine aspects of both continuous and batch milling systems. This design offers several notable advantages. For instance, they enable high production rates while maintaining the ability to handle different materials. Their flexibility appeals to various industries, especially when adjustments are frequently needed.

However, there are disadvantages. Maintenance can be complex, leading to downtime. If not monitored closely, the product quality might be inconsistent. A semi-continuous ball mill may require more energy than expected, affecting operational costs. Additionally, if material feed rates are not optimized, it can result in either waste or incomplete processes.

Tips: Regular maintenance can help minimize potential issues. Monitor the feed rate closely for optimal grinding. Always keep an eye on energy consumption. Reducing excess energy use can improve the milling operation's efficiency.

| Feature | Description | Advantages | Disadvantages |

|---|---|---|---|

| Operational Mode | Involves continuous feeding of material and intermittent discharge. | Higher efficiency in grinding over batch processes. | Complexity in operation and maintenance compared to traditional mills. |

| Material Handling | Allows for a wide range of materials to be processed. | Flexibility in handling different feed materials. | Potential for material blockages if not managed properly. |

| Power Consumption | Designed to optimize energy use during operation. | Often more energy-efficient compared to traditional batch mills. | Initial setup costs may be higher due to advanced technology. |

| Production Output | Can achieve high throughput levels. | Increased production rates and reduced idle time. | Requires careful monitoring to maintain quality. |

| Maintenance | Regular checks are needed to ensure optimal performance. | Less downtime when maintained properly. | Can be expensive if parts need to be replaced frequently. |