Leave Your Message

-

Phone

-

E-mail

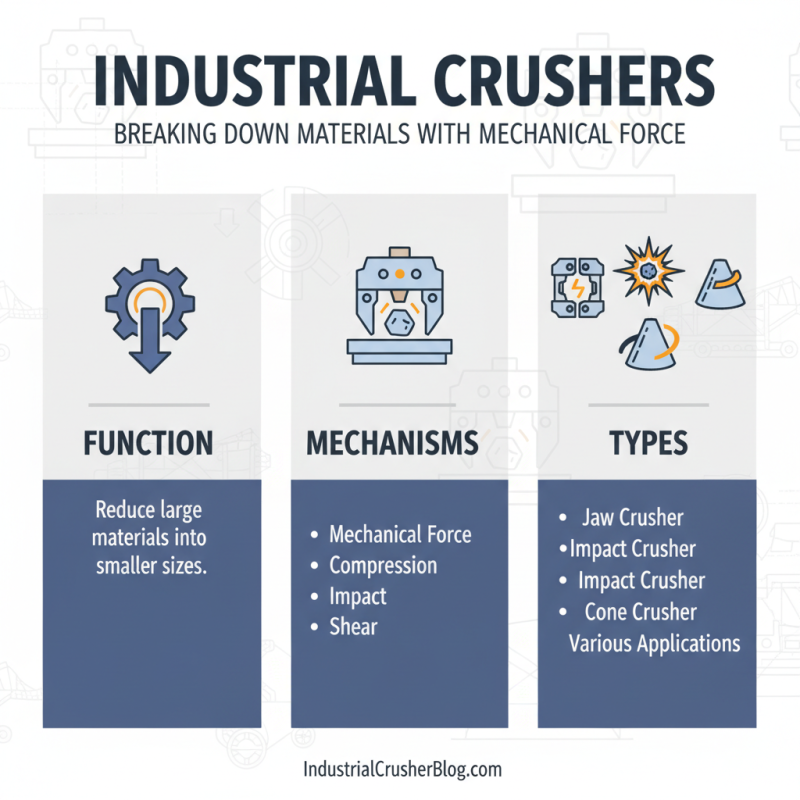

Industrial Crushers play a crucial role in various industries. They are designed to reduce large materials into smaller, manageable pieces. This process can involve materials like rocks, metal, and other raw resources. The functionality of an industrial crusher can vary based on its design and application.

Typically, these machines utilize force to break down materials. They can crush, grind, and shred depending on the required specifications. However, the efficiency of an industrial crusher can sometimes be questionable. Factors like wear and tear can impact its performance over time. Maintenance is essential for optimal operation.

It's fascinating to see how industrial crushers adapt to different tasks. Their versatility is impressive, yet understanding their limitations is important. Each model comes with specific advantages and potential drawbacks. Users must consider these factors when selecting a crusher.

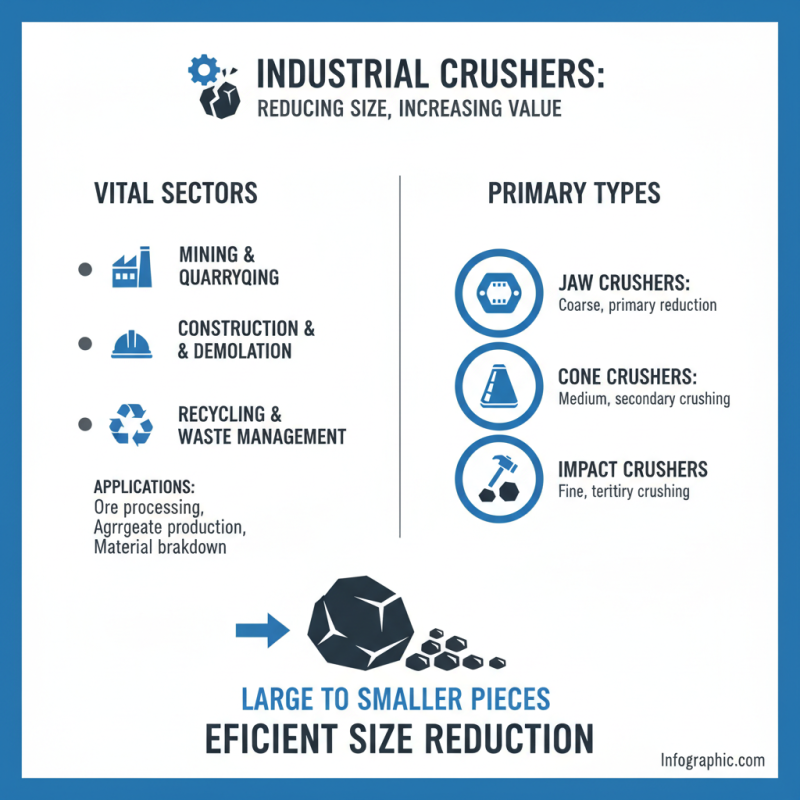

An industrial crusher is a powerful machine designed to reduce large materials into smaller, manageable pieces. These machines serve in various industries, including mining, construction, and recycling. According to a recent market research report, the industrial crusher market is expected to grow at a CAGR of 4.2% from 2022 to 2030. This growth highlights the increasing demand for efficient crushing equipment across multiple sectors.

Understanding how an industrial crusher works is crucial. These machines typically use compression, impact, or shear forces to break down materials. For example, jaw crushers use compressive force to crush hard materials. The process can generate a lot of noise and dust, which raises environmental concerns. Many companies are now exploring ways to mitigate these impacts.

Moreover, not all industrial crushers fit every application. Choosing the right type can be challenging. Users often overlook the importance of maintenance. Regular checks can prolong the machine's lifespan and efficiency. Inconsistent operation can lead to unexpected downtime. Data from production studies show that poorly maintained crushers can lose up to 20% of their efficiency. This emphasizes the need for careful selection and upkeep in order to maximize productivity.

Industrial crushers are vital in various sectors. They are used to reduce large materials into smaller pieces. Different types exist, each serving unique functions.

Jaw crushers are common in construction. They crush stones and large rocks. Their design ensures efficient size reduction. Another type is the impact crusher. It uses high-speed impact to break materials. This method is effective for soft to medium-hard materials.

Additionally, cone crushers excel in crushing hard materials. They provide precise size adjustments. However, their operation can be complex. Maintenance is critical to prevent breakdowns. Ultimately, selecting the right type depends on specific needs and materials. Understanding these applications can enhance efficiency.

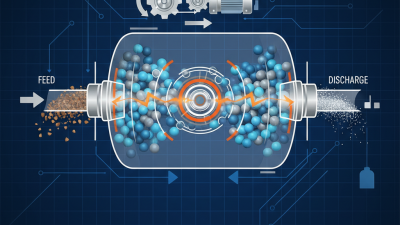

Industrial crushers are heavy-duty machines used to break down large materials. They operate using mechanical force to reduce the size of various materials. Many types of crushers exist, such as jaw, impact, and cone crushers. Each type has its own mechanism that serves different crushing applications.

Jaw crushers work by compressing materials between two plates. The top plate moves downward, applying pressure to the material. This squeezing action breaks the material into smaller pieces. Impact crushers, on the other hand, utilize high-speed impact to smash materials. A series of hammers or blow bars strike the materials, causing them to fracture.

**Tip:** Regular maintenance is crucial. Check the wear parts often. Replacing them on time can prevent larger breakdowns.

Cone crushers are another popular option. They crush materials by squeezing them between a rotating cone and a stationary outer surface. This method allows for the production of fine materials. Crushers generate heat and can wear out over time.

**Tip:** Monitor the temperature. Overheating can indicate problems. Lower efficiency might be a sign of an underlying issue.

The mechanisms of industrial crushers are vital for productivity. Understanding these can help identify potential issues. Mistakes in operation can lead to unexpected downtimes. Regular checks and proper training for operators are key.

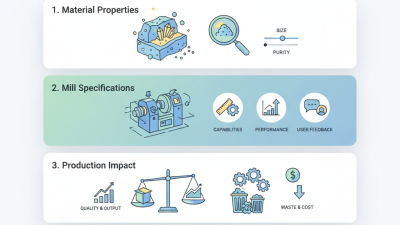

Industrial crushers play a critical role in various manufacturing processes. Understanding their key components helps in optimizing their function. The primary components include the crushing chamber, jaws, and the drive mechanism. Each part has a specific role that contributes to overall efficiency.

The crushing chamber is where the material enters. Its design affects how effectively raw materials are reduced in size. Jaws, either stationary or movable, apply pressure to crush the material. The drive mechanism powers the movement of these jaws. Without a reliable drive, crushing efficiency drops significantly.

**Tip:** Regular maintenance checks on these components can prevent unexpected breakdowns. Ignoring small issues can lead to bigger problems down the line.

Another important aspect is the discharge area. This is where crushed material exits. If this area is blocked, it can cause backups and impact productivity. Ensuring a clear path for discharge is vital for smoother operations.

**Tip:** Incorporating sensors to monitor material flow can help identify blockages early. It’s a proactive approach that enhances operational efficiency.

Remember, each component plays a role. Even minor wear and tear can affect performance. Regular assessments should be part of your maintenance routine.

This bar chart illustrates the efficiency of various types of industrial crushers. The efficiency is expressed in percentage terms, providing a clear comparison of how each type functions in a typical industrial application.

Industrial crushers play a vital role in many sectors. They reduce large materials into smaller pieces, making processes more efficient. This function serves multiple industries, from mining to recycling. Using crushers improves productivity and saves money. For instance, construction sites benefit from reduced debris. The smaller size makes handling easier.

One major benefit is versatility. Crushers can handle various materials. They process rocks, metals, and wood waste. This adaptability means businesses can streamline operations. They may switch between types of crushers based on job needs. However, this flexibility requires careful evaluation. Choosing the right type is not always straightforward. Each material has unique properties, affecting the choice of equipment.

Tips for selecting the right crusher: Consider material type. Understand the desired size reduction. Research operational costs. Knowledge is crucial in making informed decisions. A wrong choice can lead to inefficiencies. Regular maintenance is essential too. Neglecting upkeep can lead to breakdowns. In many cases, companies rush this. Reflecting on past choices can lead to better future ones.

| Industry | Type of Crusher | Application | Benefits |

|---|---|---|---|

| Mining | Jaw Crusher | Crushing rocks for mineral extraction | High efficiency, robust construction |

| Construction | Cone Crusher | Aggregate production | Uniform particle size, reduced waste |

| Waste Management | Hammer Mill | Shredding waste materials | Cost-effective waste reduction |

| Food Processing | Roll Crusher | Crushing fruits and vegetables | Maintains quality, minimizes oxidation |

| Recycling | Impact Crusher | Processing recyclable materials | High throughput, versatile use |