Leave Your Message

-

Phone

-

E-mail

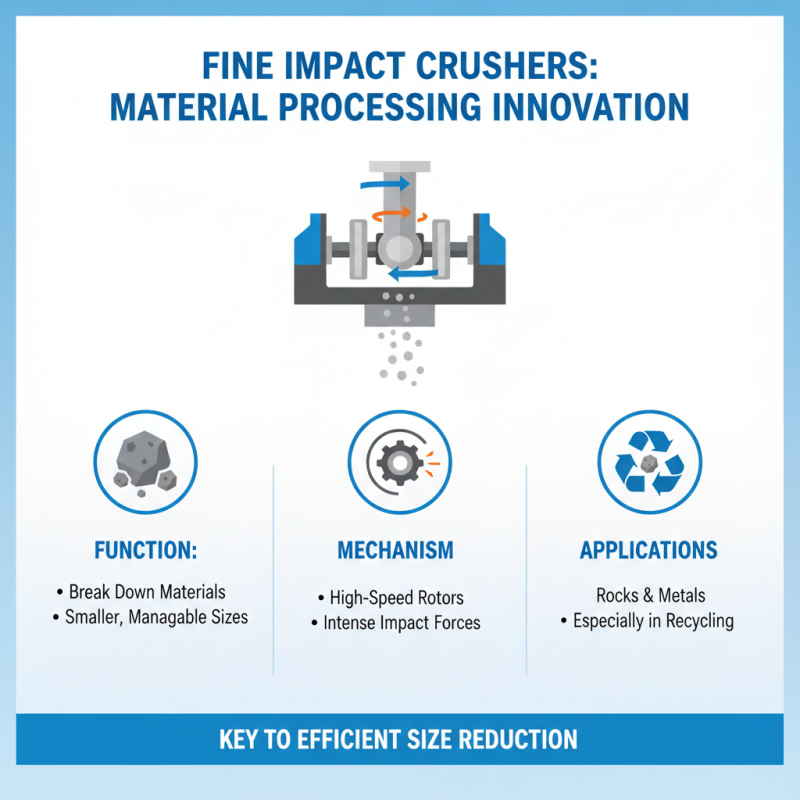

The Fine Impact Crusher is a crucial machine in the world of material processing. It specializes in refining raw materials into smaller, more manageable sizes. This type of crusher uses high-speed impact forces to break down materials effectively. It often features two or more crushing chambers, where materials are subjected to repeated impacts until they reach the desired size.

Understanding how the Fine Impact Crusher operates helps users maximize its potential. The crushing process starts with the feed material entering the machine. Then, high-speed rotors fling the material against impact plates. This results in powerful collisions that crush the materials efficiently. Additionally, the positioning of the impact plates allows some control over the final material size.

While the Fine Impact Crusher is effective, it is not without its challenges. Users may face issues such as wear and tear on components. Maintenance becomes essential to ensure optimal performance. Operators should consider the characteristics of the materials they are processing. Not all applications are ideal for a Fine Impact Crusher, which might lead to unexpected results. Thus, thoughtful planning and regular assessments are key to successful operations.

A fine impact crusher is a key piece of equipment in the crushing industry. It is designed to deliver precise and controlled particle size reduction. This machine uses high-speed impact forces to break materials down into fine particles. Its unique design allows for efficient energy use while ensuring optimal performance.

In operation, the fine impact crusher works by feeding raw materials into a chamber where high-speed rotors create a whirlwind effect. The materials collide with each other and the chamber walls, which results in size reduction. The size of the crushed material can be adjusted by changing screen sizes or rotor speeds. This versatility makes it useful for various applications, from construction to recycling.

Tips: Regular maintenance is crucial for optimal performance. Check for wear on the impact plates and replace them as needed. Monitor the feed size to ensure it is within the machine’s limits. Oversized materials can lead to poor performance or damage. Always review operational parameters if output does not meet expectations.

The fine impact crusher has some limitations. It may not be suitable for extremely hard materials. Users should evaluate their specific needs before investing. An incorrect setup can lead to inefficiency or increased costs. Understanding the machine's capabilities is essential for maximizing its potential.

This chart displays the efficiency of a fine impact crusher based on different material types. The data shows the reduction ratio achieved for each material, illustrating the crusher's effectiveness.

A fine impact crusher is essential for crushing materials into finer particles. Its design includes several key components that enhance its functionality. The rotor is the heart of the machine. It rotates at high speeds, impacting the materials and breaking them down. This rotor can face wear over time, which calls for regular inspection and maintenance.

The crushing chamber plays a pivotal role in the material flow. It ensures that material enters smoothly. However, if the chamber is not properly sized or maintained, it can lead to inefficiencies. The adjustable apron allows for the control of the final output size. However, users often forget to adjust it, leading to inconsistent results.

Another important part is the impact plates. They not only absorb shock but also guide material through the crushing process. These plates need regular checking for wear. Their effectiveness directly affects overall performance. Fine impact crushers require a well-planned maintenance strategy. Neglect can lead to costly repairs and downtime, affecting productivity. Each component works together to create a dynamic crushing environment, but overlooking one can disrupt the whole system.

Fine impact crushers are essential in the crushing industry. Their primary role is to break down materials into finer particles. They work by using high-speed rotor systems that create a powerful impact on the feed material. When materials enter the machine, they collide with the rotating rotor and are crushed against a fixed anvil.

The unique design of fine impact crushers allows for efficient size reduction. The material experiences multiple impacts, which helps achieve a uniform particle size. The adjustable settings enable operators to control the size of the output, catering to specific needs. However, improper operation may lead to excessive wear on the machine. This is a common pitfall.

Tips: Ensure regular maintenance of the crusher. Check the rotor for wear and tear frequently. Overloading the machine can cause malfunctions, so keep within recommended limits. Keep in mind that fine impact crushers work best with dry materials. Using wet or sticky materials may hinder performance.

Observing the operation can provide insights on improvements. Notice how material flows through the machine. Physical adjustments can enhance efficiency, yet be mindful of the wear patterns. Understanding these nuances can lead to better results.

Fine impact crushers are crucial in various industries. These machines are designed to produce fine materials from larger rocks. They are versatile and used in mining, construction, and recycling. Their ability to deliver consistent particle size makes them preferred in many operations. According to a report by Grand View Research, the global impact crusher market is projected to reach $4.5 billion by 2030.

In construction, fine impact crushers help in making high-quality aggregates. They reduce large stones to precise sizes, essential for concrete production. The recycling industry benefits too. By turning waste materials into reusable products, these crushers support sustainability. They are instrumental in reducing landfill waste.

**Tip:** Regular maintenance can drastically improve efficiency. Check the wear parts often. A worn-out machine can lead to poor performance.

One challenge is energy consumption. Fine impact crushers can use a lot of energy. Balancing output and energy use is vital. The industry needs to focus on developing energy-efficient models. Efficiency not only lowers costs but also reduces environmental impact.

| Industry | Application | Key Features | Benefits |

|---|---|---|---|

| Construction | Aggregates Production | High crushing ratio | Enhanced quality of aggregates |

| Mining | Mineral Processing | Versatile crushing capabilities | Increased recovery rates |

| Chemical | Chemical Powder Production | Uniform particle size | Improved product consistency |

| Recycling | Waste Material Processing | Efficient size reduction | Reduced landfill waste |

| Pharmaceutical | Active Ingredient Milling | Precisely controlled particle size | Enhanced bioavailability |

Fine impact crushers are crucial in the world of material processing. They are designed to break down materials into smaller, more manageable sizes. These machines use high-speed rotors to create intense impact forces. As a result, they can crush a variety of materials, from rocks to metals. They are particularly effective in recycling applications.

Performance metrics for fine impact crushers often focus on efficiency and throughput. Efficiency depends on factors like material type and moisture content. The speed of the rotor and the size of the crushing chamber also play significant roles. High efficiency can mean less energy consumption. However, some models struggle under different conditions. This inconsistency can lead to unexpected downtime or higher operating costs.

Analyzing the performance of these machines reveals areas for improvement. Regular maintenance can enhance efficiency but is often neglected. Operators may overlook wear and tear, leading to decreased performance. Continuous monitoring of throughput and product size can help identify potential issues. Emphasizing these metrics may improve overall operation. Balancing performance with maintenance needs can be challenging yet essential for optimal functioning.