Leave Your Message

-

Phone

-

E-mail

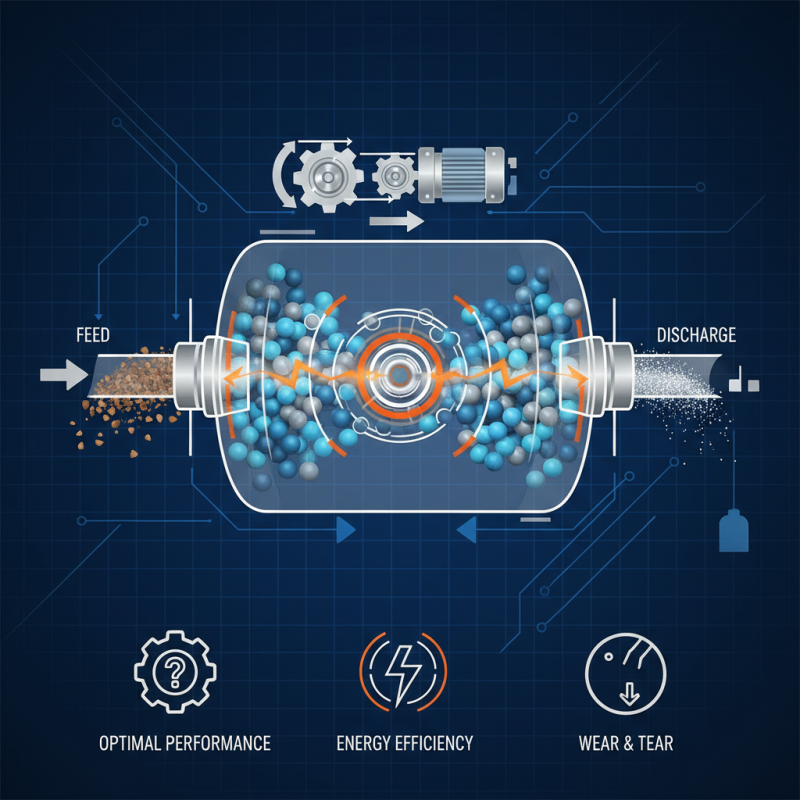

In the world of industrial processing, understanding the "Continuous Ball Mill Working Principle" is essential. Dr. Robert Lee, a renowned expert in the field, states, "The efficiency of a continuous ball mill hinges on its design and operational parameters." This insight drives many engineers to refine their processes for optimal performance and productivity.

A continuous ball mill operates with a unique design that allows the constant feed and discharge of materials. This means that it can process materials continuously for long periods. The inner workings involve rotating cylinders filled with grinding media, leading to constant friction and impact forces. However, perfecting this system is challenging. Many plants struggle with maintaining consistent product quality and energy efficiency.

Moreover, there are often issues with wear and tear on the grinding media. Operators must strike a balance between speed and quality of output. The hope is to harness advancements in technology to improve the "Continuous Ball Mill Working Principle." Yet, many still confront fundamental challenges that need thoughtful solutions and ongoing reflection.

Continuous ball mills are vital in mineral processing. They grind materials efficiently, helping in various industries. These mills operate continuously, which enhances productivity and reduces downtime. The design involves a rotating cylinder filled with grinding media and materials. The consistent feed of materials allows for a uniform grinding process.

According to industry reports, continuous ball mills can reduce energy consumption by up to 30%. This efficiency has made them popular in cement and mining sectors. However, these mills can sometimes struggle with particle size distribution. Achieving the desired fineness can be challenging. It’s vital to regularly monitor the material flow and grinding efficiency.

Tips: Monitor the mill's rotation speed closely. Adjustments can notably impact performance. Regular maintenance is essential for optimal operation. Addressing wear and tear on grinding media can improve efficiency and prolong the mill's lifespan. Consider these factors to avoid potential pitfalls in the grinding process.

This bar chart illustrates the performance metrics of a continuous ball mill, showcasing the input and output material quantities, along with the grinding efficiency and energy consumption levels. This visualization helps in understanding the operational efficiency of the mill.

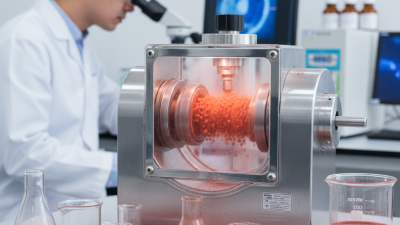

Continuous ball mills are essential in industrial processes. They consist of several key components that enable efficient operations. A typical continuous ball mill includes a rotating cylinder, grinding media, and feed and discharge systems.

The cylinder is often made of sturdy materials to withstand heavy use. Inside, steel or ceramic balls act as the grinding media. These balls collide and crush the materials into finer particles. The feed system ensures a constant supply of raw materials. It is crucial that this system maintains the right flow rate to avoid blockage and ensure uniform grinding.

The discharge system plays a vital role in maintaining efficiency. It should effectively remove the finished product to prevent overloading. However, poorly designed discharge systems can lead to backflow issues. Regular maintenance of these components is necessary. Neglect can cause downtime and affect overall productivity. Understanding the components allows for better troubleshooting and optimization in processes.

Continuous ball mills are essential in many industries, especially for grinding materials. These mills operate on the principle of continuous feeding and discharging, which increases efficiency. The material continuously enters through the inlet, making it possible to produce a consistent flow of ground product. The rotor structure and grinding media facilitate effective size reduction.

Studies show that the efficiency of continuous ball mills can reach upwards of 60%. This metric makes them attractive for bulk processing needs. For instance, the residence time of material in the mill is critical. It determines overall performance and product quality. Short residence times can lead to under-grinding, while excessively long times might cause over-grinding. Both scenarios are less than ideal.

Operational challenges persist. For example, maintaining the right balance of input materials is tricky. If the feed rate is too high, it can disrupt the flow and lead to uneven grinding. Additionally, wear and tear on the mill's internal components can affect efficiency. Operators must regularly evaluate wear patterns to optimize maintenance schedules. The goal should be to minimize downtime while ensuring consistent product quality.

Continuous ball mills are widely used in the industry for grinding various materials. Their performance is influenced by several key factors. The size of the grinding media, for instance, plays a significant role in determining the efficiency of the milling process. Larger balls generally provide higher energy but can wear out quicker. Conversely, smaller balls lead to finer grinding but may be less efficient.

Another crucial element is the feed rate. An optimal feed rate ensures a steady flow of materials through the mill. A too high feed rate can lead to incomplete grinding, while too low can decrease productivity. According to industry reports, a carefully calibrated balance can enhance output by up to 25%.

Temperature and humidity can also affect milling performance. Excessively high temperatures may alter material properties, causing clumping and uneven milling. Regular monitoring of environmental conditions can provide insights into potential issues. Notably, many operators overlook these factors until a noticeable decline in product quality occurs.

Continuous ball mills play a vital role in various industries. They are key components in processes like mineral processing, cement production, and chemical manufacturing. These mills operate with a steady flow of materials, providing continuous grinding, which enhances efficiency. They handle large quantities of materials without the need for frequent shutdowns. This feature significantly reduces operational costs and downtime.

One of the main benefits of continuous ball mills is their energy efficiency. They use less energy compared to batch mills. This is due to the ongoing operation and lower energy consumption per unit of product produced. The system can be fine-tuned easily, allowing for better control over the milling process. Users often appreciate the consistent product quality achieved through this method.

Tips: To optimize performance, regularly maintain the equipment. Always check the grinding media for wear. Adjust the feed rate to ensure consistent operation. Many users overlook these aspects, which can lead to inconsistent product quality or machine failure. Regular checks can save time and money in the long run.