Leave Your Message

-

Phone

-

E-mail

In the realm of modern manufacturing, the choice of equipment plays a pivotal role in determining the quality and efficiency of the production process. One such critical piece of machinery is the Ultrafine Ball Mill, renowned for its ability to produce finely milled materials. Selecting the right Ultrafine Ball Mill can significantly impact not only the final product's characteristics but also the overall operational workflow. With various factors to consider—including size, material compatibility, and processing capacity—manufacturers must navigate a complex landscape to find the ideal fit for their specific needs.

Understanding the core functions and advantages of an Ultrafine Ball Mill is essential for making an informed decision. These mills operate on the principle of grinding materials to a predetermined fine particle size, thereby enhancing the homogeneity and quality of the end product. Additionally, advancements in technology have introduced various features that improve efficiency and reduce energy consumption, making it crucial for manufacturers to weigh these innovations against their unique requirements. By considering the specific materials to be processed and the desired outcomes, manufacturers can ensure they invest in an Ultrafine Ball Mill that not only meets their current demands but also supports future growth.

In this article, we will explore the key considerations when choosing an Ultrafine Ball Mill, providing insights to help manufacturers streamline their selection process and enhance their production capabilities.

Ultrafine ball mills are specialized equipment designed for the grinding of materials to achieve extremely fine particle sizes, often in the range of microns. These mills utilize the principle of impact, shearing, and attrition to break down complex materials into finer particles, making them essential in industries such as pharmaceuticals, chemicals, and materials science. The ultrafine grinding process not only enhances the surface area of the material, which can improve reactivity and solubility, but also allows manufacturers to achieve specific properties required for advanced applications.

The applications of ultrafine ball mills are diverse and are primarily determined by the material characteristics and end-use requirements. In the pharmaceutical industry, for instance, these mills are crucial for preparing active pharmaceutical ingredients (APIs) at a nanoscale, which can lead to better drug delivery systems. Similarly, in the production of high-performance materials, ultrafine ball mills facilitate the creation of composites and coatings that require enhanced mechanical properties and finer grain structures.

As industries lean towards more efficient and high-quality products, understanding the technical specifications and operational capabilities of ultrafine ball mills becomes critical for aligning manufacturing processes with desired outcomes.

When selecting the right ultrafine ball mill for your manufacturing needs, several key factors must be considered to ensure optimal performance and efficiency. Firstly, the material you intend to process plays a critical role in your choice. Different materials require varying milling conditions. For example, harder materials may need mills with a higher energy input, while softer materials may not demand as much. According to a recent industry report, approximately 60% of manufacturers find that the compatibility of the mill with the specific material significantly affects the quality of the final product.

Another vital consideration is the particle size distribution required by your application. Ultrafine ball mills are designed to achieve specific particle size ranges, typically below 50 microns, but the specifications can vary across models. An analysis from the International Journal of Advanced Manufacturing Technology indicates that achieving precise particle size can enhance product quality and consistency, ultimately impacting downstream processes. Additionally, you should evaluate the mill's operational efficiency and energy consumption, as these factors directly influence production costs. Reports suggest that selecting an energy-efficient model can yield energy savings of up to 30%, further optimizing your manufacturing process.

Lastly, consider the scalability of the ultrafine ball mill. As your production needs grow, the ability to scale up operations without significant modifications to your milling setup is crucial. Industry studies indicate that investments in versatile milling technologies that allow for easy upgrades or modular expansions can significantly benefit manufacturers facing fluctuating demands. Thus, weighing these factors carefully will guide you toward selecting the most suitable ultrafine ball mill for your manufacturing objectives.

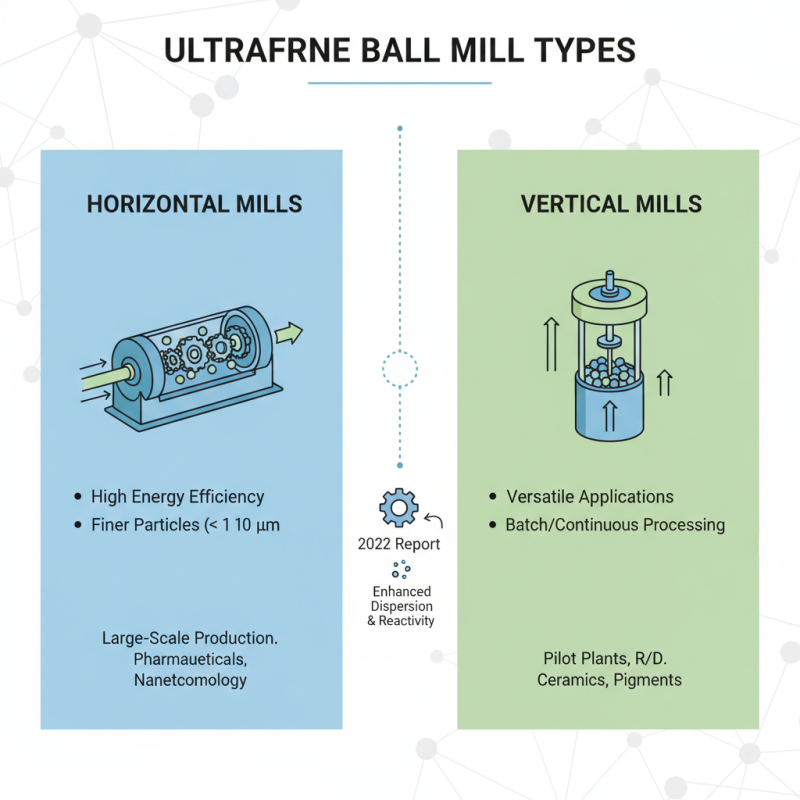

When selecting an ultrafine ball mill for manufacturing needs, understanding the various types available in the market is crucial. Ultrafine ball mills can generally be classified into two main categories: horizontal and vertical mills. Horizontal mills, often preferred for their high energy efficiency, are known to generate finer particle sizes and are suitable for large-scale production. A 2022 report from the International Journal of Advanced Manufacturing Technology highlights that these mills are capable of achieving particle sizes below 10 micrometers, enhancing dispersion and reactivity essential for industries ranging from pharmaceuticals to nanotechnology.

On the other hand, vertical ultrafine ball mills often excel in applications requiring minimal contamination and precise control over the grinding environment. These mills offer advantages such as reduced maintenance and lower operational costs. According to a study published in the Journal of Chemical Engineering, vertical mills can achieve specific energy consumption savings of up to 30% compared to traditional horizontal milling processes, making them an attractive option for manufacturers focused on efficiency and cost-effectiveness. Analyzing these types and their respective benefits can lead to a more informed decision tailored to specific production requirements.

When selecting an ultrafine ball mill for manufacturing, evaluating performance metrics is crucial to ensure the machine meets your operational requirements. Size is a primary factor; the dimensions of the mill can significantly influence the particle size distribution of the final product. An optimal mill should have a chamber that can accommodate the necessary volume of materials while providing sufficient space for grinding media, allowing for effective particle reduction.

Energy consumption is another vital consideration. The energy efficiency of an ultrafine ball mill will impact operational costs and sustainability efforts. Mills designed for efficient energy usage help minimize waste, thereby contributing to a more environmentally friendly manufacturing process. Assessing the energy input required to achieve the desired output will help in choosing a machine that balances productivity with cost-effectiveness.

Lastly, overall efficiency encompasses both output quality and processing speed. A high-efficiency mill should not only produce fine powders quickly but also maintain the integrity of the material properties. It is essential to measure parameters such as throughput and residence time to ensure the machine can deliver consistent results under your specific manufacturing conditions. Monitoring these performance metrics will guide you in making an informed decision, ultimately enhancing your production capabilities.

When considering the investment in an ultrafine ball mill, budgeting for both the initial acquisition and ongoing maintenance costs is essential for ensuring long-term profitability in manufacturing operations. According to a recent industry report by Research and Markets, the global ultrafine grinding market is expected to grow significantly, highlighting the increasing relevance of efficient milling technologies in various sectors. Initially, the cost of an ultrafine ball mill can range from $50,000 to $500,000 depending on factors like capacity, materials, and technology integration. Companies must carefully assess their production needs and potential return on investment before making a purchase.

Moreover, maintenance costs are a crucial factor often overlooked in budgeting. Studies indicate that routine maintenance can account for up to 10-20% of the total operational budget for milling equipment. Factors influencing maintenance expenses include the frequency of use, operator training quality, and the complexity of the mill's design. Data from the National Institute of Standards and Technology suggests that regular preventive maintenance not only prolongs equipment lifespan but can also reduce unplanned downtime by up to 30%. Thus, having a comprehensive maintenance plan alongside a solid initial investment can optimize performance and minimize additional financial burdens.