Leave Your Message

-

Phone

-

E-mail

Choosing the right crushing equipment is crucial for your business's success. John Smith, a seasoned expert in the crushing equipment industry, once stated, "Selecting the right tools can make or break your operation." This highlights the importance of careful consideration in your choices.

When evaluating crushing equipment, several factors come into play. Your material type greatly influences the equipment selection. Hard materials might require different machines than softer ones. The output size also matters. Every business has specific needs. Understanding these can lead to better decision-making.

Many businesses overlook maintenance costs associated with crushing equipment. These costs can add up over time. It's vital to factor in longevity and repair needs. A seemingly perfect machine may have hidden issues. Do your research and seek expert advice. The right equipment should not only meet current needs but also adapt to future demands.

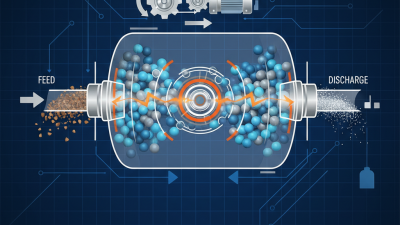

When selecting crushing equipment, understanding the types is crucial. There are three primary types: jaw, cone, and impact crushers. Each serves specific purposes and has unique benefits.

Jaw crushers are widely used for primary crushing. They excel at breaking down large, hard materials. According to a recent industry report, jaw crushers can achieve a reduction ratio of 6:1. This makes them ideal for handling rocks and minerals. However, they may not be efficient for softer materials.

Cone crushers, on the other hand, are perfect for secondary and tertiary crushing. They provide a finer product size and can handle a variety of materials. Reports indicate they are often used in mining and construction. Yet, they require more maintenance than jaw crushers, which can lead to higher operational costs.

Impact crushers are known for their key role in recycling applications. They are effective for softer materials, producing a cubic product shape. However, they can be less effective with harder materials. Understanding the specific needs of your material is essential.

**Tips**: Evaluate your material type before choosing your crusher. Consider the maintenance costs associated with each machine. Also, test their efficiency with smaller loads first. This approach helps in making informed decisions.

| Type of Crusher | Application | Materials Processed | Efficiency | Maintenance |

|---|---|---|---|---|

| Jaw Crusher | Primary crushing | Hard rocks, ores | High | Moderate |

| Cone Crusher | Secondary & tertiary crushing | Medium to hard materials | Very high | High |

| Impact Crusher | Secondary crushing | Soft to medium materials | Moderate | Lower |

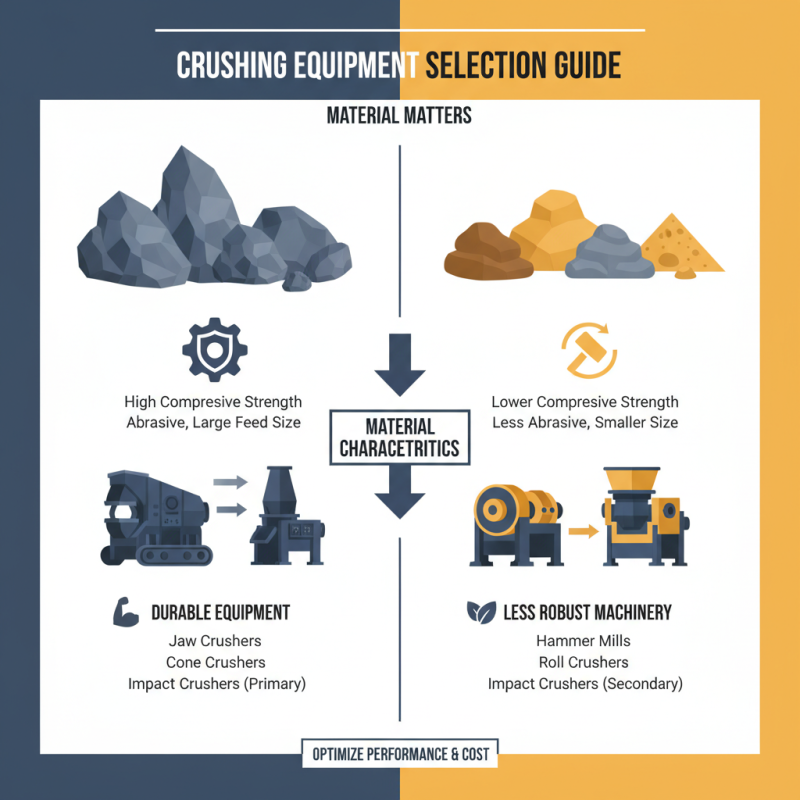

Choosing the right crushing equipment is crucial for any business. The characteristics of the material being processed play a significant role. Harder materials require more durable equipment. Soft materials, on the other hand, can be handled with less robust machinery. Consider the composition and size of the materials as these factors influence the selection process directly.

When evaluating equipment, size matters. Determine the dimensions of your materials. Larger pieces may need specialized crushers. For instance, a jaw crusher works well for bigger stones. A smaller impact crusher may be efficient for finer materials. Also, think about the desired output size. This affects the type of equipment you choose.

**Tip:** Always test your materials before making a purchase. It can reveal insights about the material's nature.

**Tip:** Don’t overlook maintenance requirements. Some crushing equipment needs more care. This could lead to higher operational costs. Balancing performance and maintenance is critical. It's essential to reflect on your long-term business needs when selecting equipment.

Choosing the right crushing equipment involves careful evaluation of production capacity needs. Businesses must assess their output goals. For example, a company aiming for a production rate of 100 tons per hour will require significantly different equipment than one targeting 50 tons.

Reports indicate that 70% of manufacturing facilities experience delays due to mismatched equipment. This can lead to inefficiencies and higher costs. Operators need to consider the desired feed size and the desired final product size. These details inform the selection process, ensuring equipment will meet demand.

It’s also crucial to reflect on flexibility. Equipment that handles various materials provides an edge but may fall short under specific demands. Think about maintenance time as well. Industry studies show that a maintenance-heavy machine can cause production halts that hinder output goals. Balancing these factors is not easy but is essential for efficient operations.

When selecting crushing equipment, cost analysis is crucial. The initial investment is often significant. However, operational efficiency can offset those costs over time. Understanding your business needs helps in making informed decisions. Sometimes, cheaper options may lead to higher maintenance expenses later. This is a vital point to consider.

Tips: Assess your production requirements. How much material do you process daily? Calculate your expected lifespan for the equipment. Longevity can make a difference. Don't overlook the energy costs, either. Efficient machines can save money long-term.

Balancing the upfront costs with future operational savings is key. For example, a higher-capacity machine may seem expensive initially. However, if it reduces labor costs and downtime, it can offer better returns. Think about what will work for your specific situation. Doing so may reveal unexpected trade-offs. Choose wisely, and reflect on all angles before making the final decision.

Selecting the right crushing equipment is essential for optimal performance, but maintenance is often overlooked. Proper care extends the life of your machines, ensuring they operate efficiently. Regular inspections are crucial. Check for wear and tear in moving parts. Clean debris from conveyors and screens frequently. Small issues can escalate into costly repairs if ignored.

Support is equally important. Establish a relationship with a reliable service provider. Timely access to parts can minimize downtime. Training staff on routine maintenance can enhance equipment longevity. Understanding the limitations of your crushing equipment is vital. Overloading can lead to breakdowns. Adjusting operational practices can prevent premature failures.

Consider investing in monitoring systems. These can provide real-time data on equipment performance. Reacting promptly to anomalies can save time and money. Sometimes, reflecting on past maintenance records reveals patterns in equipment failures. Learning from these insights can lead to improved maintenance strategies.