Leave Your Message

-

Phone

-

E-mail

Choosing the right Ultrafine Ball Mill can significantly impact your production efficiency. According to industry expert Dr. Emily Tran, "Selecting the right mill involves understanding both your material and your desired outcome." Her insights emphasize the importance of thorough analysis in this decision-making process.

The Ultrafine Ball Mill is designed to achieve exceptional particle size reduction. However, not all mills are created equal. Different models offer varying features, capacities, and operational costs. Understanding your specific needs is crucial. Are you focused on precision? Or is throughput your main concern?

Moreover, the market is filled with options, making the selection daunting. Potential buyers often overlook important factors, leading to regret down the line. It’s essential to reflect on existing production challenges. Evaluate what works and what doesn’t. This reflection helps guide you toward the perfect Ultrafine Ball Mill, ideally suited to your needs.

Ultrafine ball mills play a vital role in material processing. They are designed to grind materials to a very fine particle size. Typically, this size can be less than 1 micron. Industries such as pharmaceuticals and materials science rely on ultrafine ball mills for high-quality products. These mills can achieve exceptional uniformity and consistency in particle size, which is crucial for many applications.

Choosing the right ultrafine ball mill involves understanding its key components. For instance, the size of the grinding media is essential. Smaller media can lead to finer particles but may require longer processing times. Additionally, the design of the milling chamber can affect efficiency. It’s important to consider the material being processed. Some materials may cause wear and tear on the mill. This can impact the milling process.

Remember that not all mills perform the same way. There can be inefficiencies in different environments. Equally, user experience plays a part in performance. A beginner might struggle with setup or maintenance. This may lead to suboptimal results. Awareness of these issues can guide users in making better choices. Thus, reflecting on past experiences can lead to improved outcomes in future projects.

Choosing the right ultrafine ball mill requires careful consideration of several key factors. Particle size reduction is critical. Different applications demand specific size ranges. For instance, materials for pharmaceuticals often need 1-20 microns. A mill's ability to achieve this can significantly impact end-product quality. According to a recent industry report, 85% of particle size distribution is dependent on the mill's design and grinding parameters.

The choice of grinding media also plays a vital role. Zirconia and steel are common options, each offering unique benefits. Zirconia is more effective for tough materials, while steel provides a cost-efficient solution for softer materials. It is essential to assess the material being processed. Some mills struggle with specific hardness levels. This limitation can lead to inconsistent particle sizes and require costly adjustments down the line.

Operational efficiency and energy consumption are equally important. A well-optimized mill can reduce energy costs by up to 30%, as reported by several studies. However, many users overlook this aspect. Inefficient models not only waste energy but also deteriorate quickly. Performing regular maintenance ensures optimal performance. But, users often ignore this, leading to premature wear. Ultimately, the decision should balance efficiency, cost, and the desired outcome.

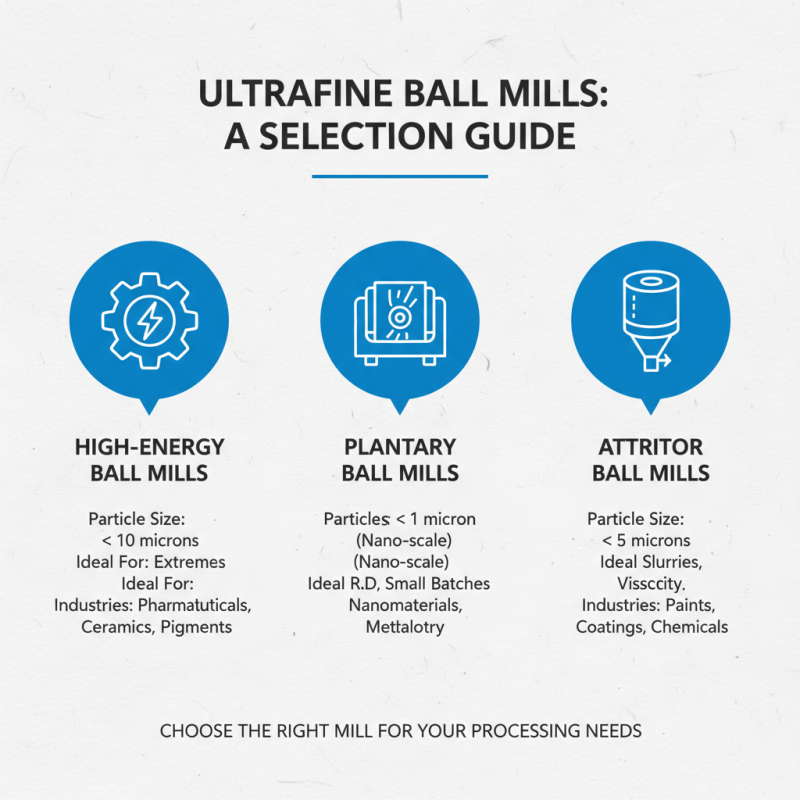

When selecting an ultrafine ball mill, understanding the various types available is essential. Different models cater to distinct processing needs. For instance, high-energy ball mills are renowned for their efficiency in fine particle size reduction. They can achieve sizes below 10 microns, making them ideal for industries requiring extreme fineness.

Another option is the planetary ball mill, which uses multiple grinding jars. A recent industry report showed these mills increase the surface area of materials significantly. They are suited for research and development in materials science. However, they can be more expensive and complex.

Choosing the right type often boils down to specific needs. Cost and throughput can influence the decision. A study noted that some users overlook the importance of maintenance and operational ease. It's easy to focus solely on output. Balancing efficiency and simplicity is crucial for long-term operational success.

Choosing the right ultrafine ball mill starts with understanding your material. Different materials have unique properties. Some are harder, while others are more brittle. Consider these traits carefully. For instance, quartz requires more robust grinding than soft minerals like talc.

Next, evaluate your grinding requirements. The desired particle size is crucial. Are you looking for a fine powder or a coarser grind? This decision affects your mill choice. Additionally, think about batch sizes. Smaller batches may need a different mill than larger operations.

Lastly, reflect on the compatibility of your materials with the grinding media. Some materials react poorly. This can lead to contamination or diminished performance. Test a small batch before committing. Such careful assessment can save time and resources later. Each decision impacts efficiency. It's worth considering all angles.

| Material Type | Hardness (Mohs) | Ideal Mill Model | Recommended Media Size (mm) | Max Feed Size (mm) | Desired Particle Size (μm) |

|---|---|---|---|---|---|

| Calcium Carbonate | 3 | Model A | 0.5 - 1.0 | 10 | 10 - 15 |

| Silica | 7 | Model B | 0.8 - 1.2 | 8 | 5 - 10 |

| Talc | 1 | Model C | 0.5 - 1.0 | 15 | 20 - 30 |

| Graphite | 1 - 2 | Model D | 0.6 - 1.0 | 10 | 15 - 25 |

| Ceramics | 5 - 7 | Model E | 0.4 - 0.8 | 6 | 10 - 20 |

When selecting an ultrafine ball mill, manufacturer reputation matters. A well-regarded manufacturer ensures consistent quality and reliability. According to a market research report, nearly 65% of users prioritize reputation when making a purchase. This emphasizes the importance of choosing wisely.

Support services are equally crucial. A manufacturer known for strong after-sales support can resolve issues more efficiently. Delays can cost businesses time and money. Surveys show that 70% of companies experience operational setbacks due to inadequate support. This can directly affect productivity and lead to dissatisfaction.

It’s wise to research customer reviews and industry feedback. Many companies overlook this step and regret it later. An apparent gap in experiences shared can be telling. If a manufacturer routinely receives complaints about support, it’s a red flag. Seek out firms with solid performance metrics and responsive services. An informed choice is much more likely to meet specific operational needs.