Leave Your Message

-

Phone

-

E-mail

Choosing the right Ultrafine Grinding Crusher can be challenging. With various options on the market, each offers unique features. One must consider their specific needs and the materials they will process.

When evaluating an Ultrafine Grinding Crusher, think about the desired particle size. Different models achieve this in various ways. Also, consider the output capacity you require. Not all grinders can meet high demands.

It’s important to reflect on the type of materials you will grind. Some crushers excel with certain substances while struggling with others. Take time to research specifications. Make sure the choice fits your operational needs.

Choosing the right ultrafine grinding crusher begins with understanding your material. Not all materials behave the same during grinding. For instance, hardness, moisture content, and particle size influence the grinding process. Harder materials may require more robust equipment. They can wear down softer machines quickly, leading to inefficiency.

Consider the end product requirements too. You might need a very fine powder, or perhaps a coarser granule is sufficient. Knowing the target particle size helps determine the type of crusher to use. Additionally, assess the volume of material you need to process. Some machines excel in high throughput, while others are better for low-volume, precise tasks.

It’s also wise to reflect on past experiences. Have you faced challenges with your current setup? Perhaps the machine jams frequently. This could indicate that it’s unsuitable for your material type. Being aware of these issues will guide your decision in choosing a more effective ultrafine grinding solution. Test different machines where possible. Sometimes, what seems perfect on paper doesn’t perform as expected.

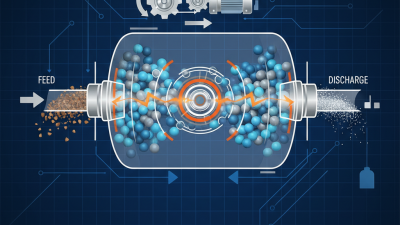

When exploring ultrafine grinding crushers, it’s essential to assess the various types available.

Ball mills are popular for their versatility. They use grinding balls to achieve fine particle size.

However, they may require longer processing times and generate heat, which can impact material quality.

Jet mills offer another approach, utilizing high-speed air to grind materials. This method can produce extremely fine particles without introducing heat. Yet, jet mills can be expensive to operate and may not be suitable for all materials.

Hammer mills are simple and effective, capable of handling a range of materials. They are easy to maintain, but their grinding precision may not meet all needs.

It’s crucial to consider your specific requirements. Evaluating particle size, moisture content, and material hardness can lead to informed decisions. Undoubtedly, testing various machines is valuable. Each has strengths and weaknesses, impacting your production goals.

Balancing cost, efficiency, and application will help pinpoint the right crusher for your facility.

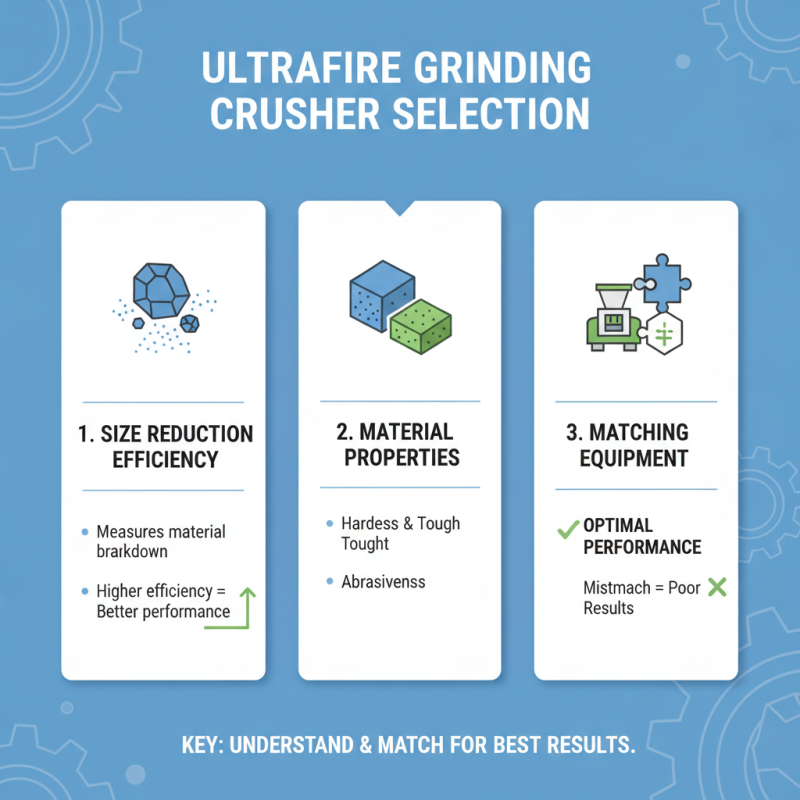

When selecting an ultrafine grinding crusher, understanding size reduction efficiency is crucial. The efficiency measures how well the equipment breaks down material. Higher efficiency translates into better performance. Consider the material properties. Some materials are tougher to grind than others. A mismatch between the crusher and material often leads to poor results.

Performance metrics play a pivotal role. Examine throughput capabilities and energy consumption. These metrics directly impact production costs. If a machine grinds slowly, it may not meet demands. Constantly gauge particle size distribution. This influences the final product quality. Inconsistent results can undermine entire operations.

Look for features that enhance usability. Some machines are complex and require specialized knowledge. If operators struggle to understand the setup, efficiency declines. Maintenance aspects are also vital. A machine that's hard to maintain can lead to unexpected downtime. Analyze how easy it is to access key components. Finally, don't overlook your specific needs. A perfect fit doesn't exist. Sometimes, compromise is necessary.

Choosing the right ultrafine grinding crusher can be challenging. When considering cost, it's vital to assess not just the initial price. Look at energy consumption and operational efficiency. An affordable model may not be the best decision if it consumes too much energy over time. This can increase your operating costs significantly.

Maintenance is another critical factor. Some crushers require extensive upkeep, leading to additional costs. Parts may need frequent replacement, or servicing could be complicated. It's essential to evaluate the long-term maintenance needs of any equipment you consider. Some machines might be low-cost but require constant attention. This can become a burden on your resources.

Operational considerations also play a vital role. How much space do you have? Some ultrafine grinders take up considerable floor space. Think about the workflow in your facility. Will the machine fit comfortably? Reflect on these aspects before making a decision. Balancing cost, maintenance, and operational factors is no easy feat. It requires thorough research and careful planning.

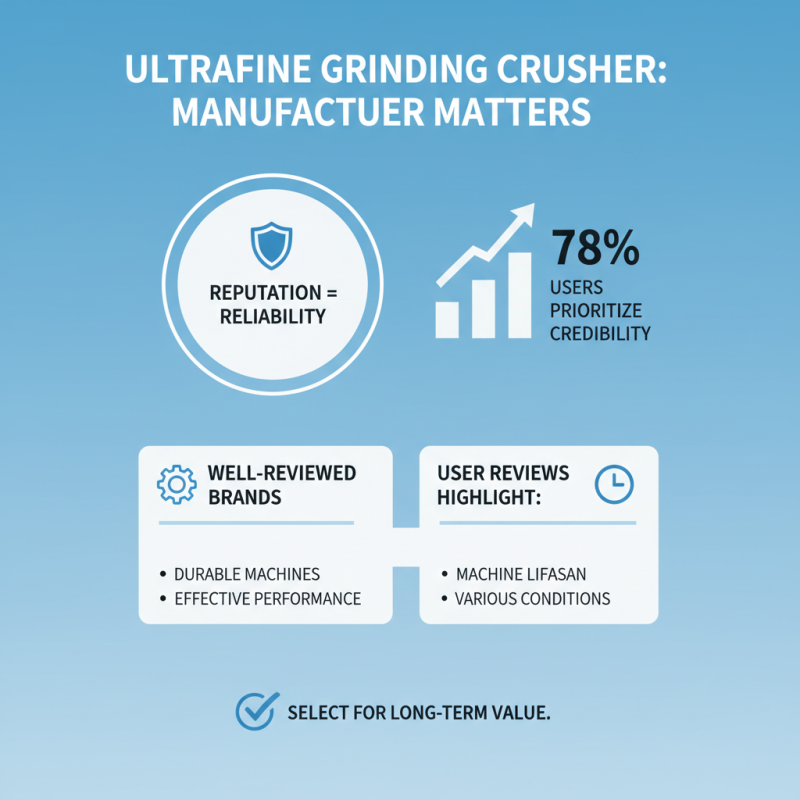

When selecting an ultrafine grinding crusher, understanding the manufacturer’s reputation is vital. A strong reputation often indicates reliability. According to industry reports, approximately 78% of users prioritize manufacturer credibility. This means that well-reviewed brands usually offer more durable and effective machines. Reviews often highlight how long these machines last and their performance in various conditions.

Customer support services play an essential role as well. The grinding process can be complex. Sometimes, users face issues that require immediate assistance. A study found that timely support increases user satisfaction by over 65%. Companies with robust support systems tend to resolve problems faster, ensuring minimal downtime. Not every manufacturer provides adequate support. Some lack clear communication channels, leading to frustration.

Faulty equipment can sometimes stem from inadequate installation or maintenance advice. Some manufacturers do not provide comprehensive guidelines, which may result in inefficient performance. Users often reflect on their experiences, noting that better support could have saved time and resources. Therefore, considering both reputation and support is crucial for making the right choice.