Leave Your Message

-

Phone

-

E-mail

In the ever-evolving landscape of mining and construction, the selection of the right equipment is crucial for operational efficiency and productivity. The Fine Jaw Crusher stands out as a vital component in the crushing process, particularly for those involved in the processing of hard and abrasive materials. According to a report by Grand View Research, the global jaw crusher market size is projected to reach USD 2.3 billion by 2025, highlighting the increasing demand for efficient and high-performance crushing machines. This burgeoning growth is driven by the rising exploration activities in the mining sector and the ascending construction spending worldwide.

A Fine Jaw Crusher is engineered for precision and durability, ensuring high-quality output material while minimizing operational costs. Studies indicate that advancements in technology have led to enhancements in both the design and functionality of these crushers, enabling them to achieve finer particle sizes with reduced energy consumption. As more industries turn to sustainable practices, the drive for energy-efficient solutions in mining and material processing has become a key consideration. In this context, understanding the criteria for choosing the best Fine Jaw Crusher for your specific needs in 2025 will not only influence performance but also impact long-term operational sustainability.

In 2025, the market for fine jaw crushers is poised for significant evolution, driven by the increasing demand for high-efficiency and precision crushing systems.

Fine jaw crushers are essential in various sectors, including mining, recycling, and construction, where the requirement for finely crushed materials is crucial. Their ability to produce a uniform particle size enables industries to achieve better material quality and efficiency, aligning with the growing focus on sustainability and resource conservation.

Understanding the market dynamics of fine jaw crushers in 2025 involves recognizing the technological advancements that enhance their performance. With innovations in materials and design, these crushers are becoming more durable and energy-efficient. Moreover, advancements in automation and monitoring systems are allowing operators to achieve optimal performance with minimal manual intervention.

As businesses seek to optimize their production processes while reducing their carbon footprint, the importance of selecting the right fine jaw crusher will be paramount in maintaining competitiveness in a rapidly evolving landscape.

When selecting a fine jaw crusher in 2025, key specifications play a crucial role in ensuring that the equipment meets your specific crushing requirements. One vital aspect to consider is the feed size and the desired product size. A fine jaw crusher should have a suitable feed opening that accommodates the maximum size of the material being processed, while also producing smaller, consistent output sizes. Understanding the material characteristics, such as hardness and abrasiveness, can further guide the selection process, as these factors influence wear rates and the overall effectiveness of the crusher.

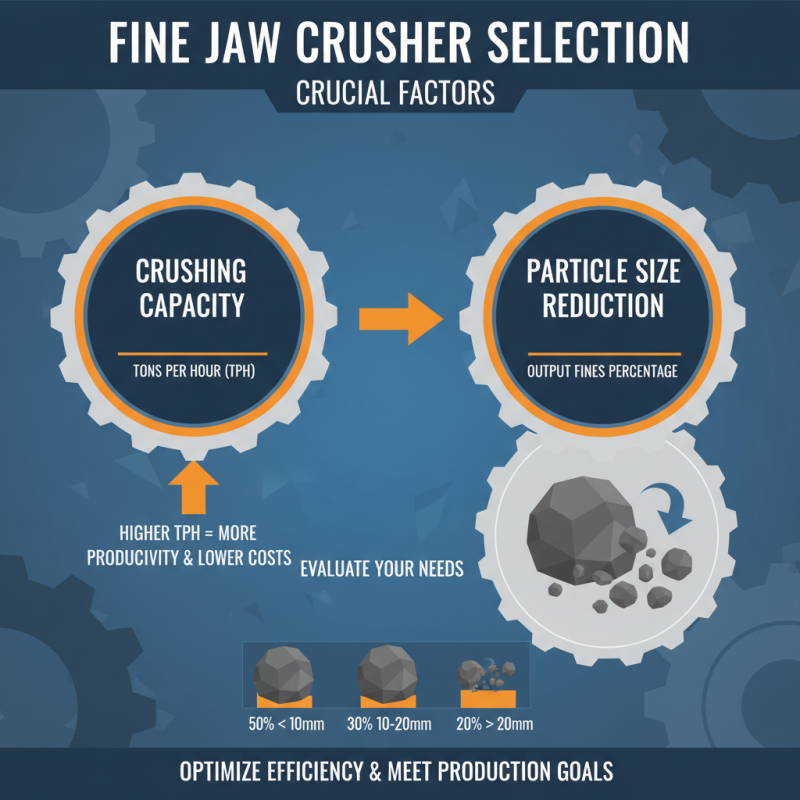

Another important specification is the crushing capacity, which is typically measured in tons per hour. This figure indicates the volume of material that the jaw crusher can efficiently process within a given timeframe. Depending on your production needs, it is essential to choose a model that balances throughput with efficient energy consumption. Additionally, consider the jaw design, as various configurations can impact the crushing efficiency and final product shape. Adjustable stroke settings can also optimize performance, allowing for flexibility in handling different materials and sizes. By focusing on these specifications, you can ensure that the selected fine jaw crusher aligns well with your operational goals.

When selecting a fine jaw crusher, it is crucial to evaluate its crushing capacities, specifically focusing on tons per hour and particle size reduction. The crushing capacity, often measured in tons per hour (TPH), indicates how much material the crusher can process in a given timeframe. This metric is vital for ensuring that the equipment can meet production requirements while maintaining efficiency. A higher TPH not only increases productivity but can also reduce operational costs due to shorter processing times.

In addition to throughput, understanding particle size reduction is essential for determining the suitability of a fine jaw crusher for your specific applications. Different industries often require specific particle size distributions to meet product specifications or enhance material performance. An effective fine jaw crusher should achieve the desired size reduction while minimizing the production of undesired fines. Therefore, operators should pay attention to both the crusher's design features and its adjustable settings that influence particle size outcomes. This dual focus on capacity and size reduction will enable businesses to select the most appropriate fine jaw crusher to optimize their crushing needs in 2025.

When choosing the best fine jaw crusher for your crushing needs in 2025, the material composition and durability of the construction materials play a critical role. High-quality steel or alloy components are essential for ensuring that your jaw crusher can withstand the rigors of daily operation. Look for crushers that utilize high tensile strength materials, as these not only enhance the longevity of the equipment but also ensure consistent performance over time. The choice of materials directly impacts not just durability but also the overall efficiency and effectiveness of the crushing process.

**Tips:** Always inquire about the material specifications used in the manufacture of the jaw crusher. A solid understanding of the alloy compositions can give you insights into the machine’s performance under various conditions, including temperature and workload.

Furthermore, consider the wear resistance of the materials used in critical components like jaws and cheek plates. Opting for materials treated or coated to resist abrasion can significantly reduce downtime caused by maintenance and part replacements. This proactive approach ensures that your equipment remains operational longer, maximizing productivity while minimizing overall costs.

**Tips:** When evaluating jaw crushers, ask for performance data related to wear rates and maintenance schedules. This information can aid in making a more informed decision that aligns with your operational needs and long-term investment strategy.

When selecting a fine jaw crusher to meet your specific crushing requirements, a critical factor to consider is the total ownership cost over time. This encompasses not just the initial purchase price but also long-term operational and maintenance expenses. According to a report by the Mining Equipment Manufacturers Association, maintenance costs can range from 10% to 20% of the total ownership cost, making it essential to analyze the reliability and efficiency of the machine before making a decision. Investing in a well-engineered fine jaw crusher could lead to reduced downtime and maintenance, significantly lowering these cumulative expenses over the equipment's lifecycle.

Moreover, energy consumption plays a substantial role in determining total ownership costs. A study published by the International Journal of Mineral Processing found that energy costs can account for up to 30% of the operating expenses in mining and aggregate processing operations. Therefore, choosing a fine jaw crusher with higher energy efficiency ratings can contribute to substantial cost savings. In 2025, as energy prices continue to rise, prioritizing crushers that incorporate innovative technologies for reduced energy consumption could provide a competitive edge, enabling operators to not only minimize their costs but also meet sustainability goals.

| Model | Initial Cost ($) | Operational Cost/Year ($) | Maintenance Cost/Year ($) | Total Cost Over 5 Years ($) |

|---|---|---|---|---|

| Model A | 50,000 | 10,000 | 5,000 | 75,000 |

| Model B | 70,000 | 12,000 | 6,000 | 108,000 |

| Model C | 60,000 | 11,000 | 4,500 | 93,500 |

| Model D | 80,000 | 15,000 | 7,000 | 127,000 |