Leave Your Message

-

Phone

-

E-mail

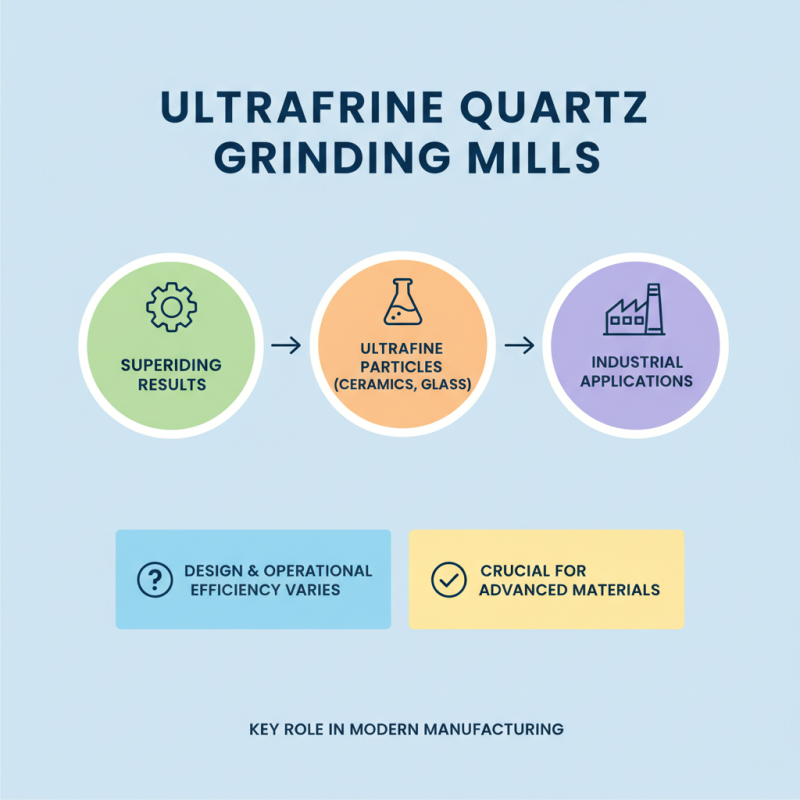

In the pursuit of superior grinding results, selecting the right Ultrafine Quartz Powder Mill is crucial. These mills play a significant role in achieving high-quality quartz powder, which is essential in various industries. However, not all mills are created equal. Some may lack efficiency or durability.

The market offers a variety of options, each with unique features. Some mills may promise high output but fall short in practical applications. An ultrafine quartz powder mill should be evaluated for factors like particle size, energy consumption, and maintenance needs. It’s important to reflect on personal requirements before making a choice.

Investing in a top-performing mill can significantly enhance productivity. Yet, without proper knowledge, one may end up with a subpar product. Understanding these intricacies helps refine the selection process. Make informed decisions to achieve the best grinding results. Your choice of an Ultrafine Quartz Powder Mill can shape future outcomes.

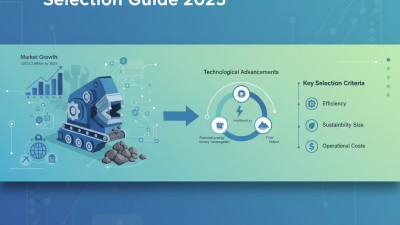

When it comes to producing ultrafine quartz powder, selecting the right milling equipment is crucial for achieving superior grinding results. The demand for ultrafine quartz is growing rapidly. Recent industry reports indicate a 10% annual growth in the ultrafine powder market, driven by applications in electronics and coatings. These markets require precise particle sizes and a high degree of uniformity.

Selecting the right mill can make a significant difference. Ball mills are popular due to their efficiency in breaking down hard materials. Jet mills, on the other hand, offer a unique approach using compressed air to achieve ultrafine sizes. Each type has its pros and cons; for example, ball mills may require longer processing times, whereas jet mills can be more expensive to operate.

Tips: Always consider the nature of the material being processed. Some materials may cause wear and tear on equipment, affecting overall efficiency. Additionally, monitor the size distribution of the resulting powder consistently. Regularly checking the quality can help in adjusting parameters for optimal results.

When choosing a mill, think about maintenance and operational costs, too. A less efficient mill might save money upfront but could lead to higher costs over time due to inefficiencies. Every choice in the milling process requires careful thought and reflection to ensure the desired outcomes are achieved.

The following bar chart illustrates the grinding efficiency of the top 5 ultrafine quartz powder mills based on various factors such as particle size reduction, energy consumption, and operational efficiency.

Ultrafine quartz powder is a versatile material with unique properties. Its fine particle size enhances its reactivity, making it valuable in various industries. These include ceramics, glass, and silicone products. The high purity of ultrafine quartz ensures that it meets strict quality standards. This purity is crucial for applications like electronics, where impurities can cause defects.

When grinding ultrafine quartz powder, achieving the right particle size is critical. The grinding process can impact the final product's quality. Incorrect parameters can lead to inconsistent results. Fine-tuning the milling settings is vital. For best performance, experiment with different speeds and times. This step requires patience and adjustment.

Tips: Always maintain clean equipment. Any contamination will affect the quality. Regularly check your grinding parameters. Different materials may require different settings. Be ready to adapt. Don't hesitate to document your findings, as this can guide future efforts. A systematic approach often yields the best outcomes.

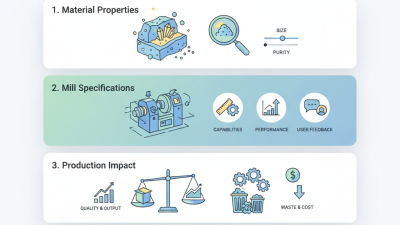

When it comes to grinding ultrafine quartz powder, several key factors influence the mill's performance. The material's hardness plays a crucial role. Quartz, being harder than many materials, requires robust milling equipment. If the machine isn't sturdy, it may wear out quickly. Regular maintenance can prevent unexpected downtimes and ensure consistent results, but many overlook this aspect.

Another important element is the grinding medium. Different materials can lead to varying outcomes. A suitable grinding medium can enhance efficiency and improve the quality of the quartz powder. Conversely, an incompatible medium might introduce contamination or lead to poor performance. It’s essential to experiment with various options to find the best match for specific needs.

Finally, the milling process itself can vary significantly. Factors such as speed, feed rate, and temperature play critical roles in the processing. Too much heat can damage the material and alter its properties. Keeping an eye on these variables is essential. It’s easy to neglect minor adjustments that can make a substantial difference in the final product. Each of these factors deserves careful consideration to achieve superior grinding results.

Ultrafine quartz powder mills play a crucial role in achieving superior grinding results. They are essential in industries that require very fine quartz particles, such as ceramics and glass manufacturing. Different models offer various features, but their efficiency often varies based on design and operational conditions.

When selecting a mill, consider the particle size and uniformity it produces. Some mills excel at creating exceptionally fine powders, while others might struggle. A closer look reveals that not all machines can handle the same throughput. It's common to find that certain models overheat or wear out quickly. This can lead to inefficient production and higher costs over time.

Additionally, user-friendliness is a key factor. Some mills are complex and have steep learning curves. This can be frustrating for new operators. Regular maintenance is also necessary. Neglecting this can lead to decreased performance and unexpected downtime. Ultimately, while features and specifications are important, the practical experiences of users can provide valuable insights for potential buyers.

When assessing the quality of ultrafine quartz powder, industry standards play a crucial role. Fine particle size distribution is essential. Reports indicate that effective grinding mills produce quartz powders with sizes below 10 micrometers. This is vital for many applications, including ceramics and electronics.

Purity levels are equally significant. Industry benchmarks suggest that high-quality ultrafine quartz should contain at least 99.5% SiO2. Any impurities can affect performance, particularly in sensitive applications. Manufacturers often face challenges in achieving this purity consistently.

Another critical aspect is the fineness of the powder, which directly influences its performance. According to industry data, powders with a high surface area can enhance reactivity in applications. However, achieving the desired fineness can be complex. Mill selection and operating parameters require careful consideration. Equipment that cannot meet these specifications may lead to unsatisfactory results. This highlights the importance of meticulous equipment evaluation and process control.

The article explores the top five ultrafine quartz powder mills renowned for their exceptional grinding performance. It begins by outlining the properties and applications of ultrafine quartz powder, highlighting its significance in various industries. Key factors that influence the performance of these mills in quartz powder grinding include the design of the grinding chamber, the type of grinding media used, and operational parameters.

A comparative analysis of the best ultrafine quartz powder mills is presented, focusing on their efficiency, output quality, and compliance with industry standards. Additionally, the article delves into the latest innovations in grinding technology, emphasizing advancements that enhance the milling process and improve the quality of ultrafine quartz powder. This comprehensive examination serves as a valuable guide for those seeking superior grinding solutions in quartz processing.