Leave Your Message

-

Phone

-

E-mail

The use of a Batch Ball Mill has become a standard in many industries for efficient grinding. According to Dr. John Smith, a leading expert in grinding technologies, "The Batch Ball Mill provides unparalleled versatility and efficiency." This type of mill optimizes processes, making it a favored choice among manufacturers.

Batch Ball Mills excel in producing fine materials while maintaining energy efficiency. They allow for precise control over the grinding process, ensuring consistent product quality. Dr. Smith emphasizes the importance of adapting the milling process to specific requirements, stating, "Customization in grinding leads to better outcomes." However, not all operations utilize Batch Ball Mills effectively. Some may overlook the need for proper maintenance and calibration.

It is essential to recognize that while Batch Ball Mills can enhance productivity, they require careful consideration in implementation. Understanding their strengths can lead to significant improvements in efficiency. Embracing this technology is crucial, but missteps in usage reveal areas for reflection and learning.

Batch ball mills offer several advantages in material grinding efficiency. They optimize the grinding process, leading to better particle size distribution. This results in more uniform material, which is critical in many industries. Unlike continuous mills, batch ball mills allow operators to adjust parameters based on the specific material being processed. The flexibility in batch sizes helps achieve targeted results for diverse applications.

Tips: Always monitor the grinding time. Over-grinding can lead to unnecessary energy consumption. Keep an eye on the temperature as well. Excess heat can affect the material properties.

Another significant benefit is reduced contamination risk. In batch processing, the risk of cross-contamination is lowered compared to other methods. This is vital for sensitive materials. Consistency in the grinding process can also lead to improved product quality. However, achieving this requires regular maintenance and attention to detail in operation.

Tips: Regularly inspect the ball mill components. Worn parts can impact performance. Conduct routine checks to prevent breakdowns.

Batch ball mills are gaining popularity due to their efficient grinding capabilities. One of the most notable advantages is improved energy consumption compared to other grinding methods. Traditional grinding techniques often waste a lot of energy. This inefficiency can lead to increased operational costs. In contrast, batch ball mills utilize energy more effectively, providing better results with lower energy input.

The design of batch ball mills allows for continuous processing, which enhances grinding efficiency. They can handle large volumes of material at once. This process reduces downtime and maximizes productivity. Another benefit is the ability to control the milling environment more accurately. Factors such as humidity and particle size can be adjusted easily. Yet, not all may experience the same efficiency; some users report inconsistent results. This variation suggests that operators need to monitor the grinding conditions closely.

Moreover, using batch ball mills can lead to less wear and tear on machinery. Improved energy consumption and lower wear can enhance overall equipment lifespan. However, achieving optimal performance requires careful oversight. Operators must be ready to adapt and refine their processes. This ongoing adjustment is key to maximizing the benefits of batch ball mills in their operations.

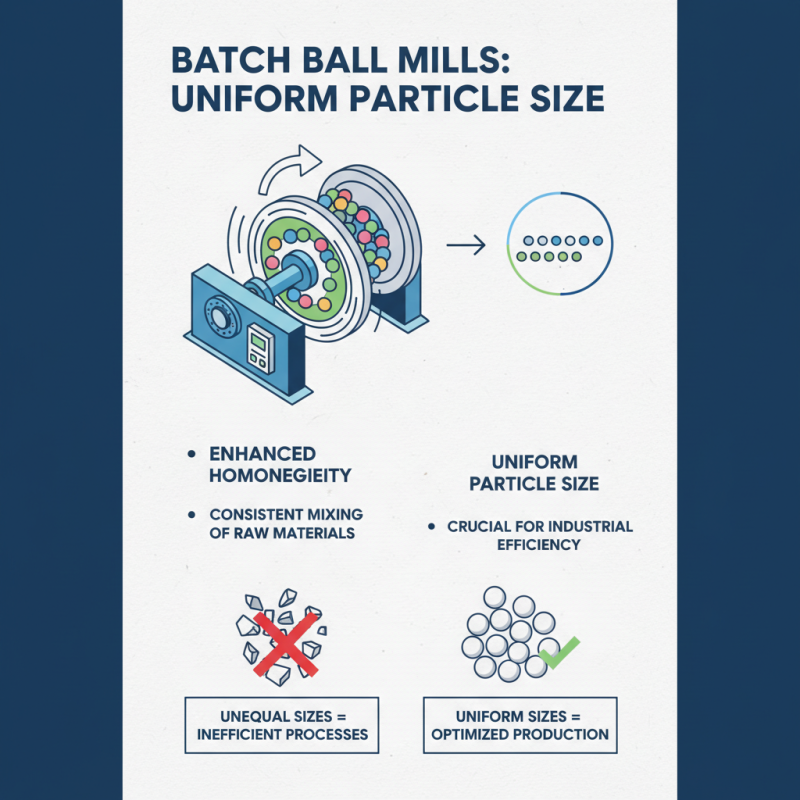

When it comes to particle size distribution, a batch ball mill truly shines. This equipment offers a remarkable advantage in achieving enhanced homogeneity in ground materials. As various raw materials are processed together, the design of the batch ball mill allows for consistent mixing. The result is a more uniform particle size, which is crucial for many industrial applications. Uneven sizes can lead to inefficiencies in subsequent processes, such as mixing or reaction rates.

In practice, achieving this level of homogeneity isn't always straightforward. Factors like the duration of milling, material types, and ball size can all affect the outcome. Sometimes, operational adjustments are needed to perfect the process. Even with careful monitoring, unexpected variations can occur. These challenges encourage users to reflect on their techniques. The focus should remain on refining methods to ensure the desired particle size distribution is consistently achieved. The benefits of a well-functioning batch ball mill extend deeply into production quality and efficiency.

Batch ball mills are known for their versatility in processing various materials. This adaptability is critical in industries such as mining, ceramics, and chemicals. According to industry reports, batch ball mills can efficiently handle hard, brittle, and even amorphous materials. Their design facilitates controlled grinding, which is essential for producing uniform particle size.

Materials like ores, minerals, and pigments require different grinding strategies. Batch ball mills allow operators to adjust parameters easily, such as grinding time and speed. This flexibility means that companies can optimize production for diverse materials. A study published in the Journal of Industrial Processing indicated that adjusting these factors improved efficiency by up to 30% in some cases.

**Tip:** Always monitor the moisture content of materials before grinding. High moisture levels can lead to clumping. This clumping disrupts the grinding efficiency.

When considering a batch ball mill, reflect on your needs carefully. Not all materials grind the same way. Sometimes, adjustments may lead to unexpected results. It's crucial to test small batches and observe the outcomes before scaling up. Understanding material behavior can prevent costly mistakes in the grinding process.

**Tip:** Keep an eye on the wear of grinding media. Over time, worn media can affect product quality and increase energy consumption. Regular checks can save resources in the long run.

Batch ball mills are a preferred choice in the industry for various reasons. One key benefit is the reduced operational costs. According to a report from a leading industry association, these mills can cut energy consumption by up to 30% when compared to traditional grinding methods. This significant decrease in energy use translates directly to lower electricity bills for facility operators.

Maintenance is another area where batch ball mills shine. They require less frequent servicing due to their robust design, which leads to fewer operational disruptions. A study indicated that the average downtime for maintenance in batch ball mills can be 20% lower than in continuous systems. This means operators can focus more on production rather than repairs. However, improper maintenance practices can lead to unexpected failures, which are costly.

Furthermore, the simplicity of the batch process reduces the complexity that often complicates maintenance. Operators report that training new staff is easier, but this does not mean oversight should be relaxed. Consistent monitoring is critical, as neglecting even minor maintenance duties can result in inefficiencies over time. Balancing cost savings with diligent upkeep is essential for maximizing the benefits of batch ball mills in any grinding operation.

| Benefit | Description | Impact |

|---|---|---|

| Reduced Operational Costs | Lower energy consumption than continuous mills. | Savings on electricity bills. |

| Lower Maintenance Requirements | Fewer moving parts lead to less wear and tear. | Reduced downtime and maintenance costs. |

| Enhanced Particle Size Distribution | Achieves a more uniform grind compared to other methods. | Improved product quality. |

| Versatility | Can be used for a variety of materials. | Increased flexibility for different production needs. |

| Simple Operation | Easy to operate and control. | Reduced training time for personnel. |

| High Grinding Efficiency | Effective in achieving fine particle sizes. | Improved production rates. |

| Consistent Output | Provides stable and predictable results. | Enhanced consistency in product quality. |

| Cost-Effective | Lower initial investment compared to continuous mills. | Quick ROI. |

| Environmentally Friendly | Minimal dust and noise pollution. | Better workplace conditions. |

| Flexibility in Batch Sizes | Can handle different batch sizes easily. | Adaptable to production needs. |