Leave Your Message

-

Phone

-

E-mail

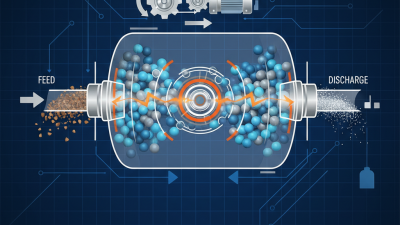

The manufacturing industry is constantly evolving, seeking more efficient processes. One significant advancement is the Semi-Continuous Grinding Ball Mill. This technology offers a unique blend of continuous and batch processing, optimizing milling operations.

The Semi-Continuous Grinding Ball Mill enhances productivity. It maintains a steady flow of materials, reducing downtime between batches. Operators report improved efficiency in particle size reduction and uniformity. However, there are challenges in setup and maintenance. These should not be overlooked.

Moreover, the cost-effectiveness of the Semi-Continuous Grinding Ball Mill is noteworthy. It can reduce energy consumption compared to traditional methods. Still, companies must evaluate their specific needs. This mill may not be the perfect fit for everyone. Exploring its benefits requires careful consideration and assessment.

Semi-continuous grinding ball mill technology has transformed the milling industry. This innovative approach combines both continuous and batch processes. It leads to improved efficiency in material processing. The design allows for a steady input of materials, which reduces downtime. Workers can manage operations more effectively, contributing to increased output.

One notable advantage is the uniform particle size achieved during grinding. Consistency is vital in many applications. However, the process can present challenges. Not all materials respond the same way. Some may require more adjustments to get optimal results. Operators need to monitor the parameters closely to ensure quality.

Additionally, energy consumption is a critical factor when considering this technology. Semi-continuous mills can be energy-efficient, but this may not always be the case. Mismanagement or improper settings can lead to excess energy use. Therefore, continual evaluation and adjustments are essential for maximizing benefits. Overall, understanding these dynamics helps create a more efficient milling operation.

Semi-continuous grinding ball mills play a vital role in modern milling processes. They are designed for efficiency and effectiveness. One key feature is their ability to provide steady input and output flow. This ensures a consistent grinding process. The design promotes the reduction of energy consumption, which is crucial for cost-saving.

These mills often combine both batch and continuous operations. This allows for greater flexibility in production. Operators can adjust parameters easily to meet changing demands. With the capability to handle a variety of materials, they offer versatility. However, some users find the initial setup challenging and require training to optimize performance.

Moreover, the maintenance of semi-continuous mills is more intricate. Regular checks are necessary to prevent breakdowns. Overlooking this can lead to inefficiencies. While the technology promises improvements, users must remain vigilant about operational practices. Understanding the equipment fully can significantly enhance productivity.

Semi-continuous grinding ball mills play a vital role in efficient milling processes. These mills provide enhanced output and consistent particle sizes. The designed continuous operation reduces downtime significantly. Operators can load materials without halting production, maximizing efficiency.

This milling method allows for precise control over the grinding process. The adjustable settings let manufacturers tailor the fineness of the product. However, achieving the perfect balance can be challenging. Parameters like feed rate and grinding time require careful monitoring. Small adjustments can lead to noticeable differences in product quality.

Moreover, maintenance plays a crucial role in performance. Regular checks help identify wear and tear. Overlooking maintenance could result in unexpected downtimes. Operators must be proactive to ensure consistent efficiency. While the semi-continuous design offers many benefits, it also demands attentive management. Recognizing these details is essential for truly efficient milling.

The semi-continuous grinding ball mill offers several advantages that enhance the milling process. The chart above illustrates key benefits such as energy efficiency, product quality, reduced carbon footprint, lower operational costs, and minimized maintenance needs, reflecting their impact on achieving efficient milling results.

Semi-continuous grinding ball mills are vital in various industries. They streamline the milling process and enhance efficiency. In the mining sector, these mills are crucial for processing minerals. They grind materials consistently, improving extraction rates. This system minimizes downtime, which often leads to increased productivity.

In the food industry, semi-continuous grinding is also valuable. It helps in producing fine particles of ingredients. For example, spices are ground to desired textures, ensuring uniformity. However, maintaining the right balance of grind size can be tricky. Inadequate adjustments might lead to inconsistent product quality.

Moreover, the chemical industry utilizes these mills for pigments and coatings. These materials often require precise sizes for optimal performance. In this context, fine-tuning the operation can be challenging. A slight oversight in parameters can affect the final product. Overall, while the semi-continuous grinding ball mill offers efficiency, it also pushes for constant improvement and monitoring.

The semi-continuous grinding ball mill offers distinct advantages over traditional milling methods. Its design allows for higher efficiency and better energy utilization. Reports indicate that energy consumption can be reduced by as much as 30% compared to conventional systems. Such efficiency means lower operational costs, which is critical for industries looking to maximize profits.

Moreover, the semi-continuous process improves particle size distribution. Traditional milling often results in uneven grinding, leading to wasted materials. In contrast, the semi-continuous method achieves a more consistent particle size, essential for processes like mineral processing. A study highlights that 80% of particles can reach the desired size significantly faster with this method.

However, challenges remain. Implementing semi-continuous systems may require upfront investment and training. Some facilities may also face difficulties in adaptation. These factors should not be overlooked, as they can impact overall efficiency. Continuous improvement in operational practices is necessary to fully leverage the benefits of semi-continuous milling.

| Feature | Semi-Continuous Grinding Ball Mill | Traditional Milling Methods |

|---|---|---|

| Energy Efficiency | High efficiency; reduced energy consumption | Generally lower efficiency; higher energy use |

| Product Quality | Consistent and superior product quality | Higher variability in product quality |

| Operational Flexibility | Easy to adjust for different materials | Limited adjustment capabilities |

| Maintenance | Lower maintenance needs | Higher maintenance requirements |

| Production Capacity | Greater output with continuous operation | Generally lower output; batch processing |

| Environmental Impact | Reduced waste and emissions | Higher waste and emissions |