Ball Mill for Slurry Processing

product video

Pulp ball mill product description

Continuous slurry ball mill is a monomer continuous slurry ball mill for preprocessing ceramic plastic material. Its main purpose is to transform the physical state of plastic material from solid to liquid mud. Raw materials from the loader to the special mud feeding machine, according to the process can be loaded formula material can also be loaded single material, feed from the feeder to the slurry ball mill, at the same time add water and necessary chemical materials, raw materials in the ball mill body by the grinding body to grind the slurry, from the outlet continuous slurry and sifted into the underground pool for storage. At the same time, the outlet is equipped with a screen to remove impurities, so as to complete the whole grinding process. The whole ball grinding process is fully automatic control, raw materials, water and chemical materials according to the formula according to the program setting accurate addition.Unique bearing support supporting belt drive design, can make the ball mill speed up, improve the pulp efficiency.

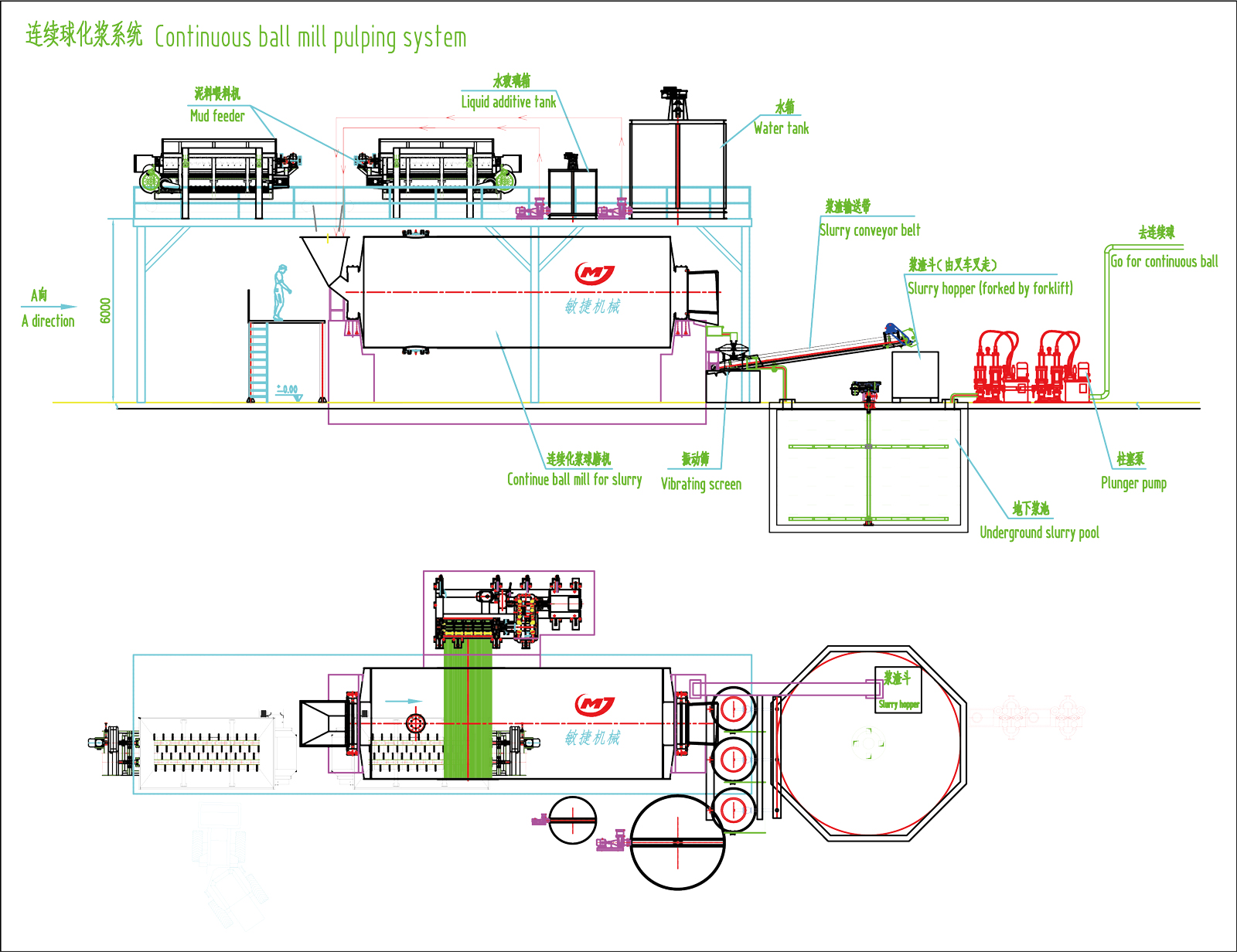

Schematic diagram of continuous ball layout

Main technical parameters

| Model | m ³ Volume | m m Cylinder size | k W Power | r/min Reducer model | Speed | Type of lining | Grinding media |

| QHJ30106 | 82 | Ø3000X10600 | 200-6 | ZLY400 | 9.5-13.8 | Rubber lining | Medium high aluminum ball |

| QHJ32106 | 92 | Ø3200X10600 | 280-6 | ZLY450 | 9-13 | Rubber lining | Medium high aluminum ball |

| QHJ36106 | 103 | Ø3600X10600 | 315-6 | ZLY500 | 8.5-12.3 | Rubber lining | Medium high aluminum ball |